What is a Ball Grid Array (BGA)?

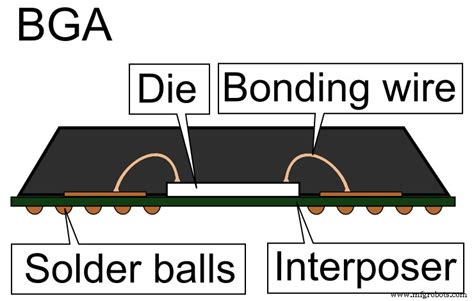

A Ball Grid Array (BGA) is a surface-mount packaging technology that uses a grid of solder balls to connect the IC package to the PCB. The solder balls are arranged in a matrix on the underside of the BGA package, providing a high-density interconnect solution. BGA packages are widely used in various applications, including:

- Microprocessors

- Graphics Processing Units (GPUs)

- Field Programmable Gate Arrays (FPGAs)

- Application-Specific Integrated Circuits (ASICs)

- Memory devices

Advantages of BGA Packages

- High interconnect density: BGA packages offer a high number of interconnects in a small footprint, enabling the packaging of complex ICs with a large number of I/O pins.

- Improved electrical performance: The short lead lengths and low inductance of BGA packages result in better electrical performance compared to other packaging technologies, such as Quad Flat Packages (QFPs).

- Enhanced thermal performance: BGA packages have a large surface area for heat dissipation, allowing for better thermal management of high-power devices.

- Reduced package size: BGA packages enable a smaller package size compared to other packaging technologies, making them suitable for space-constrained applications.

Disadvantages of BGA Packages

- Difficulty in inspection: The solder joints in BGA packages are hidden beneath the package, making visual inspection challenging. X-ray inspection or other specialized techniques are required to verify the integrity of the solder joints.

- Rework challenges: Reworking BGA packages can be difficult and time-consuming, as it requires specialized equipment and skilled operators to remove and replace the package.

- Higher assembly costs: The assembly process for BGA packages is more complex and requires specialized equipment, resulting in higher assembly costs compared to other packaging technologies.

What is a Land Grid Array (LGA)?

A Land Grid Array (LGA) is a surface-mount packaging technology that uses a grid of contact pads, or lands, to connect the IC package to the PCB. Unlike BGA packages, LGA packages do not have solder balls. Instead, the connection between the package and the PCB is achieved through a compression force applied by a socket or a clamping mechanism. LGA packages are commonly used in:

- Microprocessors

- Chipsets

- High-performance computing applications

Advantages of LGA Packages

- Improved thermal performance: LGA packages have a direct metal-to-metal contact between the package and the socket, resulting in better thermal conductivity and heat dissipation compared to BGA packages.

- Enhanced mechanical reliability: The compression force applied to LGA packages ensures a reliable and stable connection between the package and the socket, reducing the risk of solder joint failures.

- Ease of replacement: LGA packages can be easily replaced without the need for soldering, making upgrades and maintenance more convenient.

- Reduced package height: LGA packages have a lower profile compared to BGA packages, as they do not have solder balls, enabling thinner designs.

Disadvantages of LGA Packages

- Higher socket costs: LGA packages require a specialized socket or clamping mechanism to establish the connection between the package and the PCB, which can be more expensive than the assembly process for BGA packages.

- Limited I/O density: LGA packages have a lower I/O density compared to BGA packages, as the contact pads are larger and require more spacing between them.

- Mechanical stress: The compression force applied to LGA packages can cause mechanical stress on the PCB, requiring careful design considerations to prevent warping or damage.

Comparison of BGA and LGA Packages

| Parameter | BGA Packages | LGA Packages |

|---|---|---|

| Interconnect method | Solder balls | Contact pads (lands) |

| I/O density | High | Lower than BGA |

| Electrical performance | Good, short lead lengths and low inductance | Similar to BGA |

| Thermal performance | Good, large surface area for heat dissipation | Better than BGA, direct metal-to-metal contact |

| Mechanical reliability | Dependent on solder joint integrity | Enhanced, compression force ensures stable connection |

| Assembly process | Soldering | Compression force (socket or clamping) |

| Rework | Difficult and time-consuming | Easier, packages can be replaced without soldering |

| Package height | Higher due to solder balls | Lower, no solder balls |

| Cost | Higher assembly costs | Higher socket costs |

Applications of BGA and LGA Packages

BGA and LGA packages are used in a wide range of electronics applications, depending on the specific requirements of the device and the system. Some common applications include:

BGA Package Applications

- Mobile devices (smartphones, tablets)

- Graphics cards

- Gaming consoles

- Network switches and routers

- Wireless communication devices

LGA Package Applications

- Desktop and laptop computers (CPUs, chipsets)

- Servers and workstations

- High-performance computing systems

- Embedded systems

- Industrial control systems

Frequently Asked Questions (FAQ)

- Can BGA packages be replaced with LGA packages?

-

In most cases, BGA and LGA packages are not interchangeable due to differences in their interconnect methods and package dimensions. Switching from one package type to another would require a redesign of the PCB and the packaging solution.

-

Are LGA packages more expensive than BGA packages?

-

The cost comparison between LGA and BGA packages depends on several factors, such as the package size, I/O count, and the specific application. While LGA packages require more expensive sockets, the overall cost may be offset by the simplified assembly process and easier maintenance compared to BGA packages.

-

Which package type offers better electrical performance, BGA or LGA?

-

Both BGA and LGA packages offer good electrical performance, with short lead lengths and low inductance. The specific performance characteristics may vary depending on the package design and the application requirements.

-

Can LGA packages be soldered to the PCB?

-

No, LGA packages are not designed to be soldered to the PCB. They require a socket or a clamping mechanism to establish the electrical and mechanical connection between the package and the PCB.

-

Are there any other grid array package types besides BGA and LGA?

- Yes, there are several other grid array package types, such as:

- Pin Grid Array (PGA): Uses a grid of pins to connect the package to the PCB.

- Column Grid Array (CGA): Similar to BGA, but uses columns instead of solder balls.

- Ceramic Column Grid Array (CCGA): A variant of CGA that uses ceramic substrates for high-reliability applications.

Conclusion

BGA and LGA packages are two widely used packaging technologies in the electronics industry, each with its own advantages and disadvantages. BGA packages offer high interconnect density, good electrical performance, and a smaller package size, making them suitable for a wide range of applications. On the other hand, LGA packages provide better thermal performance, enhanced mechanical reliability, and easier maintenance, making them a preferred choice for high-performance computing and server applications.

When choosing between BGA and LGA packages, designers must consider factors such as the required I/O density, thermal management, mechanical reliability, assembly process, and cost. Understanding the differences between these package types helps in selecting the most suitable packaging solution for a given application, ensuring optimal performance, reliability, and cost-effectiveness.

As technology advances, packaging technologies continue to evolve, with new variations and improvements being introduced to meet the ever-increasing demands of the electronics industry. Regardless of the specific package type, the goal remains the same: to provide a robust and efficient means of connecting ICs to PCBs, enabling the development of innovative and high-performance electronic devices.

Leave a Reply