Introduction to Battery Charge Circuits

A battery charge circuit is an electronic circuit designed to safely and efficiently charge rechargeable batteries. The main purpose of a battery charge circuit is to control the charging process, ensuring that the battery is charged to its optimal capacity without overcharging or undercharging, which can lead to reduced battery life or even damage to the battery.

Battery charge circuits are essential components in various electronic devices, such as smartphones, laptops, power banks, and electric vehicles. They play a crucial role in managing the power flow from the charging source to the battery, monitoring the battery’s voltage and current levels, and terminating the charging process when the battery reaches its full capacity.

Key Components of a Battery Charge Circuit

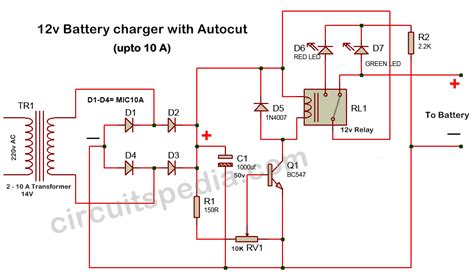

A typical battery charge circuit consists of several key components that work together to ensure a safe and efficient charging process. These components include:

-

Power Source: The power source provides the necessary energy to charge the battery. It can be an AC adapter, a USB port, or a solar panel, depending on the application.

-

Voltage Regulator: The voltage regulator maintains a constant voltage level suitable for charging the battery. It steps down the input voltage from the power source to the required charging voltage of the battery.

-

Current Limiter: The current limiter restricts the maximum current that can flow into the battery during the charging process. It prevents the battery from drawing excessive current, which can cause overheating and damage.

-

Charge Controller: The charge controller is the brain of the battery charge circuit. It monitors the battery’s voltage and current levels, and adjusts the charging process accordingly. It also implements various charging algorithms to optimize the charging efficiency and prolong the battery’s life.

-

Temperature Sensor: The temperature sensor monitors the battery’s temperature during the charging process. It ensures that the battery stays within a safe operating temperature range to prevent overheating and thermal runaway.

-

Battery Protection Circuitry: The battery protection circuitry includes safety features such as overcharge protection, overdischarge protection, and short-circuit protection. These features prevent damage to the battery and ensure safe operation.

Customized Functions for Perfect Charging

To achieve perfect charging, battery charge circuits can be customized with various functions tailored to the specific requirements of different applications. Here are five customized functions that can enhance the charging performance and prolong the battery’s life:

1. Multi-Stage Charging Algorithm

A multi-stage charging algorithm optimizes the charging process by dividing it into multiple stages, each with different voltage and current levels. The most common multi-stage charging algorithm is the CC-CV (Constant Current-Constant Voltage) method, which consists of two main stages:

-

Constant Current (CC) Stage: During this stage, the battery is charged with a constant current until it reaches a predetermined voltage level, typically around 70-80% of its full capacity. The constant current allows for fast charging while preventing overheating.

-

Constant Voltage (CV) Stage: Once the battery reaches the predetermined voltage level, the charging process switches to the constant voltage stage. During this stage, the voltage is maintained at a constant level, while the current gradually decreases as the battery approaches its full capacity. This stage helps to prevent overcharging and extends the battery’s life.

Some advanced battery charge circuits may include additional stages, such as a trickle charge stage for maintaining the battery’s charge level when it’s not in use, or a top-off charge stage for ensuring maximum capacity.

2. Temperature Compensation

Temperature plays a crucial role in the charging process, as it affects the battery’s performance, safety, and longevity. High temperatures can cause the battery to degrade faster, while low temperatures can reduce the charging efficiency and capacity.

To address this issue, battery charge circuits can incorporate temperature compensation functions. These functions adjust the charging voltage and current based on the battery’s temperature, ensuring optimal charging performance across a wide temperature range.

For example, at low temperatures, the charging voltage may be slightly increased to compensate for the reduced charging efficiency. Conversely, at high temperatures, the charging voltage and current may be reduced to prevent overheating and thermal runaway.

Temperature compensation functions rely on temperature sensors, such as thermistors or NTC (Negative Temperature Coefficient) sensors, to monitor the battery’s temperature accurately. The charge controller uses the temperature data to adjust the charging parameters in real-time, ensuring safe and efficient charging under various environmental conditions.

3. Battery Health Monitoring

Battery health monitoring functions track the battery’s performance and condition over time, providing valuable insights into its overall health and remaining life. These functions can help users make informed decisions about when to replace the battery and how to optimize its usage for maximum longevity.

Some common battery health monitoring parameters include:

-

State of Charge (SoC): SoC represents the battery’s remaining capacity as a percentage of its full capacity. It helps users estimate the remaining runtime and plan their device usage accordingly.

-

State of Health (SoH): SoH indicates the battery’s current condition compared to its original condition when it was new. It takes into account factors such as capacity degradation, internal resistance, and self-discharge rate. A low SoH suggests that the battery may need replacement soon.

-

Cycle Count: The cycle count tracks the number of complete charge-discharge cycles the battery has undergone. Each battery has a limited number of cycles before its performance starts to degrade significantly. Monitoring the cycle count can help predict the battery’s remaining life.

Battery charge circuits with health monitoring functions use advanced algorithms and machine learning techniques to analyze the battery’s performance data over time. They can provide users with real-time updates on the battery’s health status, estimated remaining life, and suggestions for optimizing the battery’s usage.

4. Fast Charging Support

Fast charging has become a highly desirable feature in modern electronic devices, especially smartphones and laptops. It allows users to charge their devices quickly, minimizing downtime and enhancing user experience.

Battery charge circuits that support fast charging can deliver higher charging currents to the battery, significantly reducing the charging time compared to standard charging methods. However, implementing fast charging requires careful design considerations to ensure safety and prevent damage to the battery.

Some key aspects of fast charging support in battery charge circuits include:

-

Higher Current Handling: Fast charging circuits must be capable of handling higher charging currents, typically several times higher than standard charging currents. This requires robust components and proper thermal management to prevent overheating.

-

Intelligent Power Management: Fast charging circuits need intelligent power management systems that can dynamically adjust the charging current and voltage based on the battery’s condition, temperature, and other factors. This ensures safe and efficient charging while preventing overcharging or overheating.

-

Battery Chemistry Compatibility: Not all battery chemistries are suitable for fast charging. Lithium-ion batteries, particularly those with advanced chemistries like lithium-polymer or lithium-iron-phosphate, are more compatible with fast charging due to their higher power density and improved safety features.

-

Communication Protocols: Fast charging often involves communication between the charger and the device being charged, using protocols like USB Power Delivery (USB-PD) or Qualcomm Quick Charge. These protocols allow the charger and the device to negotiate the optimal charging voltage and current, ensuring compatibility and safety.

Fast charging support in battery charge circuits has revolutionized the way we charge our devices, making it more convenient and time-efficient. However, it’s essential to ensure that the fast charging implementation is safe, reliable, and compatible with the specific battery chemistry and device requirements.

5. Wireless Charging Compatibility

Wireless charging has gained popularity in recent years, offering a convenient and cable-free way to charge electronic devices. Battery charge circuits that are compatible with wireless charging can enable devices to be charged wirelessly using inductive charging technology.

In wireless charging, the battery charge circuit is connected to a wireless charging receiver coil, which is typically integrated into the device. When the device is placed on a wireless charging pad, the receiver coil receives power from the pad’s transmitter coil through electromagnetic induction.

To ensure compatibility with wireless charging, battery charge circuits must be designed with specific features and considerations:

-

Wireless Power Receiver: The battery charge circuit must include a wireless power receiver module that can efficiently convert the received AC power from the receiver coil into DC power suitable for charging the battery.

-

Foreign Object Detection (FOD): FOD is a safety feature that detects the presence of metallic objects on the wireless charging pad, which can cause overheating or interference. The battery charge circuit should have FOD capabilities to prevent charging when foreign objects are detected.

-

Qi Compatibility: Qi is the most widely adopted wireless charging standard, developed by the Wireless Power Consortium (WPC). Battery charge circuits that are Qi-compatible ensure interoperability with a wide range of wireless charging pads and devices.

-

Efficient Power Transfer: Wireless charging typically has lower efficiency compared to wired charging due to power losses in the inductive coupling process. Battery charge circuits should be designed to maximize the power transfer efficiency, minimizing losses and ensuring faster charging times.

-

Thermal Management: Wireless charging can generate additional heat due to the inductive coupling process. Battery charge circuits must have adequate thermal management features, such as temperature monitoring and power limiting, to prevent overheating and ensure safe operation.

Wireless charging compatibility in battery charge circuits offers users the convenience of charging their devices without the need for cables, enhancing the overall user experience. However, it’s crucial to ensure that the wireless charging implementation is safe, efficient, and compliant with industry standards to ensure interoperability and reliability.

Conclusion

Battery charge circuits play a vital role in ensuring safe, efficient, and optimized charging of rechargeable batteries in various electronic devices. By incorporating customized functions such as multi-stage charging algorithms, temperature compensation, battery health monitoring, fast charging support, and wireless charging compatibility, battery charge circuits can enhance the charging performance, prolong the battery’s life, and improve the overall user experience.

As the demand for longer battery life and faster charging continues to grow, advancements in battery charge circuit design and technology will be crucial in meeting these challenges. With the increasing adoption of renewable energy sources and the growing popularity of electric vehicles, battery charge circuits will also play a significant role in enabling the transition towards a more sustainable future.

Frequently Asked Questions (FAQ)

1. What is the purpose of a battery charge circuit?

A battery charge circuit is designed to safely and efficiently charge rechargeable batteries by controlling the charging process, monitoring the battery’s voltage and current levels, and ensuring that the battery is charged to its optimal capacity without overcharging or undercharging.

2. What are the key components of a battery charge circuit?

The key components of a battery charge circuit include a power source, voltage regulator, current limiter, charge controller, temperature sensor, and battery protection circuitry. These components work together to ensure a safe and efficient charging process.

3. What is a multi-stage charging algorithm?

A multi-stage charging algorithm optimizes the charging process by dividing it into multiple stages, each with different voltage and current levels. The most common multi-stage charging algorithm is the CC-CV (Constant Current-Constant Voltage) method, which consists of a constant current stage followed by a constant voltage stage.

4. How does temperature compensation work in battery charge circuits?

Temperature compensation functions in battery charge circuits adjust the charging voltage and current based on the battery’s temperature, ensuring optimal charging performance across a wide temperature range. These functions rely on temperature sensors to monitor the battery’s temperature accurately and adjust the charging parameters in real-time.

5. What are the benefits of wireless charging compatibility in battery charge circuits?

Wireless charging compatibility in battery charge circuits offers users the convenience of charging their devices without the need for cables, enhancing the overall user experience. It allows devices to be charged wirelessly using inductive charging technology, provided that the battery charge circuit is designed with specific features and considerations, such as a wireless power receiver, foreign object detection, and Qi compatibility.

Leave a Reply