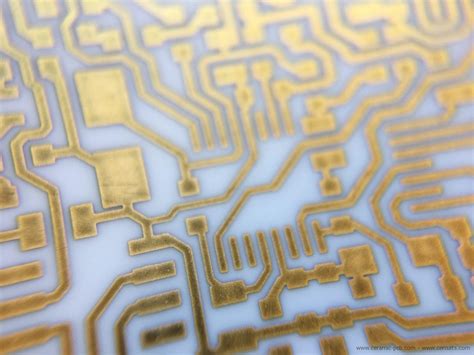

Introduction to AlN-Alumina PCBs

Aluminum Nitride (AlN) and Alumina (Al2O3) are two popular ceramic materials used as substrates for manufacturing high-performance printed Circuit Boards (PCBs). These ceramIC Substrates offer unique properties that make them ideal for applications requiring excellent thermal conductivity, high electrical insulation, and mechanical stability.

Properties of AlN and Alumina Substrates

| Property | AlN | Alumina |

|---|---|---|

| Thermal Conductivity | 170-200 W/mK | 20-30 W/mK |

| Dielectric Constant | 8.6 @ 1 MHz | 9.8 @ 1 MHz |

| Dielectric Strength | 15 kV/mm | 16.7 kV/mm |

| Coefficient of Thermal Expansion (CTE) | 4.5 ppm/°C | 6.5 ppm/°C |

| Flexural Strength | 400 MPa | 400 MPa |

| Density | 3.26 g/cm³ | 3.90 g/cm³ |

AlN substrates exhibit higher thermal conductivity compared to Alumina, making them suitable for applications that generate substantial heat and require efficient heat dissipation. On the other hand, Alumina substrates provide excellent electrical insulation and are more cost-effective than AlN.

Applications of AlN-Alumina PCBs

High-Power Electronics

AlN-Alumina PCBs are extensively used in high-power electronic applications, such as power converters, motor drives, and switch-mode power supplies (SMPS). The excellent thermal conductivity of AlN substrates helps dissipate heat generated by power components, ensuring reliable operation and extended device lifespan.

RF and Microwave Circuits

Ceramic substrates like AlN and Alumina are preferred for high-frequency applications, including RF and microwave circuits. Their low dielectric loss and high dielectric constant enable the design of compact and efficient circuits operating at gigahertz frequencies. AlN-Alumina PCBs find applications in radar systems, satellite communication, and wireless infrastructure.

LED Lighting

AlN substrates are widely used in LED lighting applications due to their high thermal conductivity. Efficient heat dissipation is crucial for maintaining the performance and longevity of high-power LEDs. AlN PCBs provide a reliable platform for mounting and cooling LED packages, ensuring optimal light output and reliability.

Aerospace and Defense

The aerospace and defense industries rely on AlN-Alumina PCBs for their high reliability and robustness in harsh environments. These ceramic substrates can withstand extreme temperatures, vibrations, and shock, making them suitable for avionics, missile systems, and satellite electronics.

Advantages of One-Stop Manufacturing

Streamlined Production Process

One-stop manufacturing simplifies the production process by consolidating all the necessary steps under one roof. From substrate preparation to circuit patterning, component assembly, and final testing, a single vendor handles the entire PCB Manufacturing process. This streamlined approach reduces lead times, minimizes communication gaps, and ensures better Quality Control.

Cost Efficiency

Engaging a one-stop manufacturer for AlN-Alumina PCBs can lead to cost savings compared to sourcing from multiple vendors. By eliminating the need for multiple shipments and reducing inventory management complexities, one-stop manufacturing optimizes the supply chain and lowers overall costs.

Consistent Quality

One-stop manufacturing ensures consistent quality throughout the PCB production process. With a single vendor overseeing all the manufacturing steps, there is better control over material selection, process parameters, and quality inspections. This leads to higher yield rates and fewer defects in the final product.

Customization Flexibility

Working with a one-stop manufacturer allows for greater customization flexibility. Customers can collabor

Leave a Reply