What is an AC PCB Board?

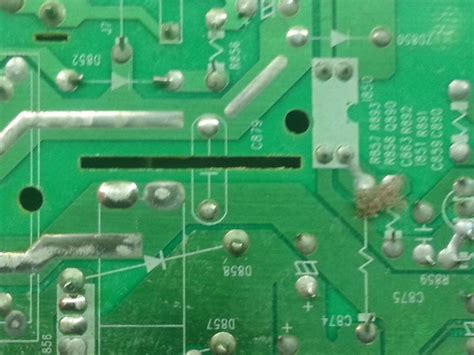

An AC PCB board is a printed circuit board specifically designed for air conditioning units. It serves as the brain of the air conditioner, controlling various components and ensuring smooth operation. The PCB board is populated with electronic components, such as resistors, capacitors, transistors, and microcontrollers, which work together to regulate the air conditioner’s functions.

Key Components of an AC PCB Board

1. Microcontroller

The microcontroller is the central processing unit (CPU) of the AC PCB board. It is responsible for executing the programmed instructions and coordinating the activities of other components on the board. The microcontroller receives input signals from sensors and user controls, processes the information, and sends output signals to control the air conditioner’s functions.

2. Power Supply Circuit

The power supply circuit on the AC PCB board converts the incoming AC voltage to the required DC voltage levels for the various electronic components. It typically includes a transformer, rectifier, and voltage regulator to ensure a stable and consistent power supply to the board.

3. Sensor Interfaces

AC PCB boards incorporate various sensor interfaces to monitor and regulate the air conditioner’s performance. These sensors may include:

- Temperature sensors: Measure the ambient temperature and provide feedback to the microcontroller for temperature control.

- Humidity sensors: Monitor the humidity levels and adjust the air conditioner’s dehumidification function accordingly.

- Pressure sensors: Detect the refrigerant pressure and ensure the system operates within safe limits.

4. User Interface

The user interface on the AC PCB board allows users to interact with the air conditioner and control its settings. It typically includes:

- Buttons or touch panels for power on/off, mode selection, temperature adjustment, and fan speed control.

- LED indicators or LCD displays to provide visual feedback on the air conditioner’s status and settings.

5. Relay and Switching Circuits

Relay and switching circuits on the AC PCB board control the activation and deactivation of various components, such as the compressor, fan motor, and valves. These circuits receive signals from the microcontroller and switch the corresponding components on or off based on the desired operating conditions.

Functionality of an AC PCB Board

The AC PCB board orchestrates the overall functioning of the air conditioner by performing the following tasks:

-

Temperature Regulation: The microcontroller on the PCB board continuously monitors the ambient temperature using the temperature sensor. It compares the measured temperature with the user-set target temperature and controls the compressor and fan motor accordingly to maintain the desired temperature.

-

Dehumidification: If the air conditioner has a dehumidification function, the PCB board utilizes the humidity sensor to detect the moisture levels in the air. When the humidity exceeds a certain threshold, the microcontroller activates the dehumidification mode to remove excess moisture from the air.

-

Fan Speed Control: The PCB board allows users to adjust the fan speed through the user interface. The microcontroller sends signals to the fan motor control circuit to regulate the fan speed based on user preferences or automatic settings.

-

Protective Functions: The AC PCB board incorporates various protective functions to ensure the safe operation of the air conditioner. These may include:

-

Overload protection: Prevents damage to the compressor and other components due to excessive current draw.

- Overheat protection: Shuts down the air conditioner if the internal temperature reaches a critical level.

- Freeze protection: Prevents the evaporator coils from freezing up during low-temperature operation.

Troubleshooting Common AC PCB Board Issues

When an air conditioner malfunctions, the PCB board is often the first place to investigate. Here are some common issues that can arise with AC PCB boards and their potential solutions:

1. No Power

If the air conditioner fails to turn on, the issue could be related to the power supply circuit on the PCB board. Check for any blown fuses, loose connections, or damaged components in the power supply section. If the problem persists, the PCB board may need to be replaced.

2. Erratic Behavior

If the air conditioner exhibits erratic behavior, such as randomly turning on and off or not responding to user input, the microcontroller or its associated circuits may be faulty. In such cases, professional diagnosis and repair or replacement of the PCB board may be necessary.

3. Sensor Malfunction

Faulty sensors can lead to incorrect temperature readings or improper operation of the air conditioner. If the temperature sensor is not providing accurate readings, the PCB board may need to be replaced. Similarly, if the humidity sensor or pressure sensor is malfunctioning, it should be replaced to restore proper functionality.

Maintenance and Care of AC PCB Boards

To ensure the longevity and reliable performance of your air conditioner’s PCB board, follow these maintenance tips:

-

Keep the air conditioner clean: Regular cleaning of the air conditioner’s filters, coils, and vents helps prevent dust and debris from accumulating on the PCB board and its components.

-

Avoid moisture exposure: Protect the PCB board from moisture and humidity to prevent corrosion and short circuits. Ensure proper drainage of condensate and fix any leaks promptly.

-

Schedule professional maintenance: Have your air conditioner serviced by a professional technician at least once a year. They can inspect the PCB board for any signs of wear, corrosion, or damage and address any issues before they escalate.

-

Handle with care: If you need to handle the PCB board for any reason, always use proper electrostatic discharge (ESD) precautions to avoid damaging the sensitive electronic components.

Frequently Asked Questions (FAQ)

1. Can I replace the AC PCB board myself?

While it is possible to replace the AC PCB board yourself if you have the necessary technical skills and tools, it is generally recommended to seek professional assistance. Incorrect handling or installation of the PCB board can lead to further damage or safety hazards.

2. How long does an AC PCB board typically last?

The lifespan of an AC PCB board depends on various factors, such as the quality of the board, operating conditions, and maintenance. On average, a well-maintained PCB board can last between 10 to 15 years. However, exposure to moisture, dust, or extreme temperatures can shorten its lifespan.

3. Are all AC PCB boards interchangeable?

No, AC PCB boards are not universally interchangeable. Each air conditioner model has a specific PCB board designed to match its requirements and specifications. Using an incompatible PCB board can result in malfunction or damage to the air conditioner.

4. How much does it cost to replace an AC PCB board?

The cost of replacing an AC PCB board varies depending on the air conditioner model, the complexity of the board, and labor charges. On average, the cost can range from $200 to $600 or more. It is advisable to obtain quotes from multiple professional service providers to compare prices and services.

5. Can a faulty AC PCB board cause the air conditioner to consume more energy?

Yes, a faulty AC PCB board can lead to increased energy consumption. If the PCB board is not regulating the air conditioner’s functions properly, it may cause components like the compressor or fan motor to run inefficiently or continuously, resulting in higher energy bills.

Conclusion

The AC PCB board is a critical component that ensures the smooth and efficient operation of your air conditioner. Understanding its components, functionality, and common issues can help you better maintain and troubleshoot your air conditioning unit. Regular maintenance, proper care, and professional servicing can extend the lifespan of your AC PCB board and keep your air conditioner running optimally for years to come.

Leave a Reply