Introduction

Pi and FR4 stiffener are two important terms that are commonly used in electronics design and manufacturing. Though they sound similar, they refer to completely different things. This article will provide a detailed comparison between pi and FR4 stiffener to help understand their key differences.

What is Pi?

Pi (π) is a mathematical constant that represents the ratio of a circle’s circumference to its diameter. It is an irrational number that is commonly approximated as 3.14159. Though pi is just a number, it has great significance in mathematics, especially geometry, trigonometry and calculus. Some key facts about pi:

- Pi is an irrational number – it has an infinite number of digits after the decimal that do not repeat in a pattern.

- The value of pi is the same for all circles – it establishes a constant relationship between the diameter and circumference.

- Pi is integral to calculating area and volume of circular and spherical objects.

- Pi can be computed using infinite series, continued fractions, iterated functions and geometric constructions.

- March 14 (3/14) is celebrated as Pi day worldwide, because 3, 1 and 4 are the first three significant digits of π.

So in summary, pi is a transcendental mathematical constant that relates a circle’s diameter to its circumference. It has crucial applications across mathematics, physics, engineering and many other fields.

What is FR4?

FR4 or Flame Retardant 4 is a grade designation for glass-reinforced epoxy laminate sheets used to manufacture printed circuit boards (PCB). The FR4 material consists of woven fiberglass cloth with an epoxy resin binder that is flame resistant. Some key facts about FR4 boards:

- FR4 is the most common PCB substrate material today because of its favorable electrical properties and cost. Over 90% of rigid PCBs are made from FR4.

- The FR4 material has good mechanical strength, excellent electrical insulating properties and can withstand high temperatures.

- The flame retardant additives in FR4 give it fire resistance so that the material does not sustain combustion.

- FR4 laminates are made by impregnating fiberglass sheets with different formulations of epoxy resin. The resin content varies between 30-70%.

- FR4 dielectric constant ranges from 4.2 to 4.5 over a wide frequency range up to GHz levels.

- FR4 PCBs have relatively high thermal conductivity for heat dissipation in electronics.

So FR4 laminates form the core part of the PCB structure and provide it with mechanical support, electrical insulation as well as fire resistance.

Difference between Pi and FR4 Stiffener

Now that we have understood what pi and FR4 refer to individually, let’s compare them to highlight the key differences:

| Parameter | Pi | FR4 Stiffener |

|---|---|---|

| Definition | Mathematical constant that is ratio of circle’s circumference to diameter. | Glass-reinforced epoxy laminate sheets used for PCB substrate. |

| Nature | Abstract irrational number with infinite digits after decimal. | Physical material made from fiberglass and flame-retardant resin. |

| Discovered by | Pi is a mathematical concept known since ancient times. | FR4 was developed by the National Electrical Manufacturers Association (NEMA). |

| Uses | Crucial in geometry, trigonometry, physics and many other fields. | Used as insulating substrate for mounting components in PCBs. |

| Value | Always equal to 3.141592… (rounded to many decimal places). | Varies based on resin content and fiberglass weave. |

| Constancy | Pi remains constant for all circular objects. | FR4 properties differ slightly across manufacturers. |

| Computing Pi | Requires iterative numerical methods, infinite series, etc. | FR4 is manufactured by set industrial processes. |

Therefore, the key points of difference are:

- Pi is an abstract mathematical concept while FR4 is a physical material.

- Pi is a dimensionless number while FR4 has measurable engineering properties.

- Pi has been known for millennia while FR4 was invented recently for PCBs.

- Pi is used in mathematical calculations while FR4 is used to build physical PCBs.

- Pi has a fixed value while FR4 properties vary slightly based on materials and processes.

So in summary, pi and FR4 stiffener are completely different things – one is a mathematical constant while the other is an engineering material. They should not be confused with each other when dealing with electronics design and fabrication.

FR4 Stiffeners in PCBs

Now that we have seen how pi and FR4 differ, let us understand more about FR4 stiffeners and their usage in PCBs.

What is an FR4 Stiffener?

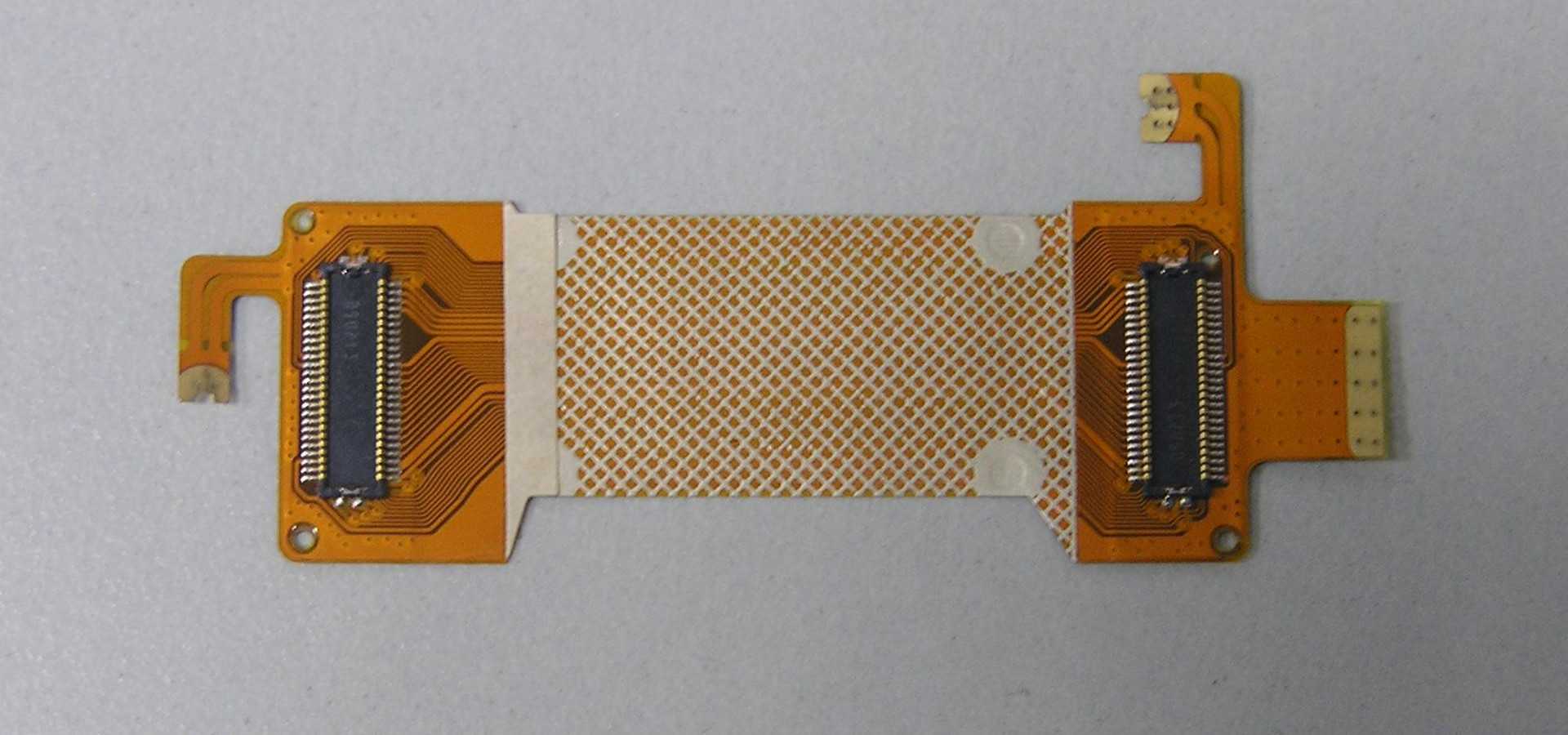

An FR4 stiffener is a piece of high density FR4 laminate that is mounted on a PCB to strengthen and support it. Here are some key points:

- Stiffeners help prevent warpage and twisting of the PCB due to temperature changes during processing.

- They reinforce weak areas of the PCB that are subject to high stress and vibration.

- Stiffeners improve rigidity near component mounting locations, connectors and along edges/corners.

- Multiple small stiffeners are often more effective than one large one.

- FR4 material is used because its thermal expansion matches that of the PCB.

Where are Stiffeners Used?

FR4 stiffeners are commonly used:

- Near large or heavy components like transformers, heat sinks, inductors etc.

- Below connectors and sockets that undergo frequent mating cycles.

- Along PCB edges and corners.

- In densely packed boards with small component-to-component spacing.

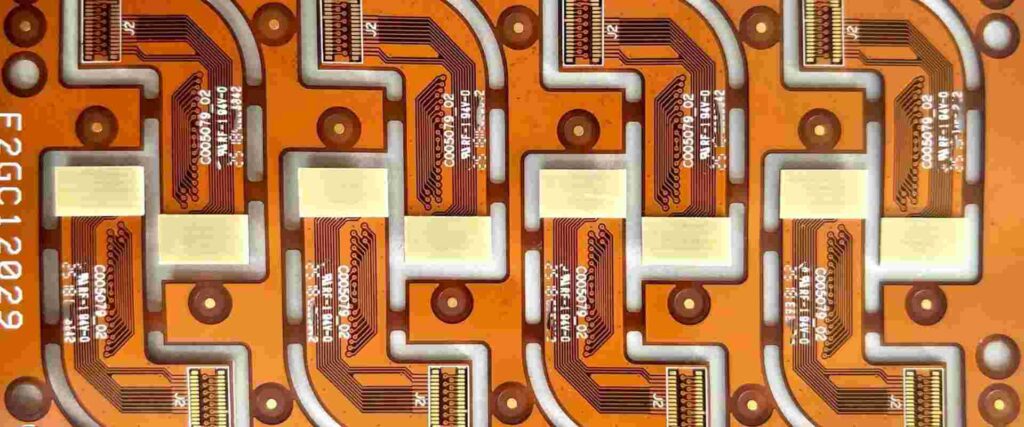

- In flexible-rigid PCB designs.

- Across gaps in the PCB area, e.g. in multi-board assemblies.

Advantages of Using Stiffeners

Some benefits of using FR4 stiffeners in PCB designs:

- Prevent warpage that can cause open circuits or short circuits.

- Avoid stress failures near component leads and solder joints.

- Enable use of thinner PCB materials to reduce weight and cost.

- Support flexible PCB areas and high density interconnects.

- Improve thermal management by reducing board flexing.

- Enable reliable performance under shock, vibration and flexing.

- Allow safe handling of populated boards without damage.

Stiffener Design Considerations

Some points to consider when designing PCB stiffeners:

- Think about movement, flexing and stresses on the PCB during operation.

- Do thermal analysis to account for expansions and contractions.

- Allow small gaps around stiffener perimeter for adhesive.

- Align stiffener symmetrically under the area to be strengthened.

- Use daisy chain routing for breakaway tabs around stiffener.

- Adjust stiffener thickness based on PCB thickness and components.

- Select adhesive to match PCB and stiffener thermal properties.

- Stress relief cutouts can be used around pad vias under stiffener.

So in summary, FR4 stiffeners are important reinforcements in many PCB designs today to prevent failure under stress. They require careful design consideration.

Summary

- Pi is an infinite irrational mathematical constant relating a circle’s diameter to its circumference.

- FR4 is a flame-retardant glass-epoxy material used as the insulating substrate in most PCBs.

- Pi has fixed value while FR4 properties vary slightly with materials and processes.

- Pi is used in mathematical formulae whereas FR4 stiffeners provide physical reinforcement in circuit boards.

- FR4 stiffeners strengthen parts of the PCB subject to stress, vibration, flexing or warpage.

- Careful design of stiffeners is needed based on PCB layout, thermals, components and other factors.

So in conclusion, pi and FR4 stiffeners are completely distinct – understanding their differences allows proper usage in electronics engineering applications.

Frequently Asked Questions

What are some common areas where FR4 stiffeners are used in PCBs?

Some common areas where FR4 stiffeners are used are:

- Below large, heavy components like capacitors, inductors, transformers, sockets etc.

- Along the edges and corners of PCB cards.

- Around cutouts and openings in the PCB.

- Across gaps between modules in multi-PCB assemblies.

- In flexible-rigid PCB designs.

- Near high density BGA packages.

- Under frequently mated connectors and cable attachments.

How does the thickness of an FR4 stiffener get decided?

The thickness of the FR4 stiffener is chosen based on factors like:

- Thickness of the PCB material itself.

- Amount of strengthening required.

- Clearances between components and board.

- Height of components that need to be accommodated.

- Structural stiffness desired.

- Dynamic bending and vibration levels.

Generally, the stiffener thickness is made equal to or slightly greater than the PCB thickness. Thicker stiffeners are used when more reinforcement is needed.

Does the FR4 stiffener get electrically connected to the PCB ground plane?

Typically FR4 stiffeners are not connected directly to the ground plane on the circuit board. They are solely meant for providing mechanical reinforcement. However, in some RF/microwave boards, the stiffeners may be grounded to the chassis or enclosure using metal clips or screws. This prevents any electromagnetic interference.

How are components and traces routed on a PCB area with stiffener?

On a PCB area where an FR4 stiffener is present, clearance gaps are provided between the stiffener edges and components or traces. Smaller components can be routed under the stiffener by providing clearance cutouts. Traces are routed between stiffener edges by making sure electrical spacing rules are met. Stress relief cutouts can be used when traces pass under pad vias within stiffener outline.

What process is used to mount the stiffener on the PCB?

The FR4 stiffener is mounted on the PCB using adhesive bonding. Common adhesives used are epoxy, acrylic or polyurethane. The adhesive is applied by screen printing, dispensing or manual application. The adhesive thickness and curing method is selected to ensure robust stiffener bonding as per the PCB assembly process.

Leave a Reply