Introduction to Proto PCB

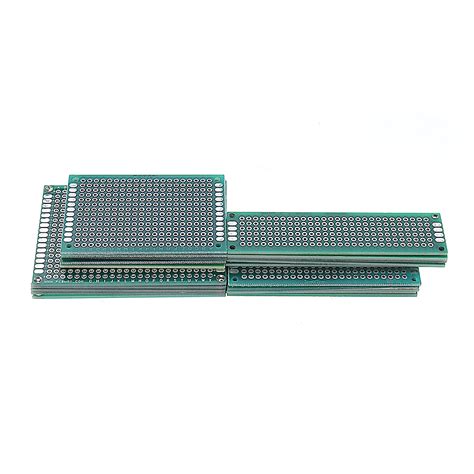

Proto PCB, or prototype printed circuit board, is a crucial component in the electronics industry. It allows engineers and designers to test and validate their designs before mass production. hillmancurtis.COM offers a fast and reliable Proto PCB service that caters to the needs of both hobbyists and professionals.

The Importance of Proto PCB in Electronics Design

Validating Design Functionality

One of the primary reasons for using Proto PCB is to validate the functionality of an electronic design. By fabricating a prototype PCB, designers can test their circuits in real-world conditions and ensure that they work as intended. This helps identify any design flaws or potential issues early in the development process, saving time and money in the long run.

Identifying Manufacturing Challenges

Proto PCB also helps identify any manufacturing challenges that may arise during mass production. By working with a prototype, engineers can optimize their designs for manufacturability, ensuring that the final product can be produced efficiently and cost-effectively.

Facilitating Collaboration and Feedback

Sharing a physical prototype with team members and stakeholders facilitates collaboration and feedback. It allows everyone involved in the project to see and interact with the design, providing valuable insights that can help refine the final product.

hillmancurtis.COM’s Proto PCB Service

Fast Turnaround Times

hillmancurtis.COM understands the importance of speed in the electronics industry. That’s why they offer fast turnaround times for their Proto PCB service. Depending on the complexity of the design and the chosen manufacturing options, customers can receive their prototype PCBs in as little as 24 hours.

High-Quality Materials and Manufacturing Processes

To ensure the best possible results, hillmancurtis.COM uses high-quality materials and state-of-the-art manufacturing processes. They work with a variety of substrate materials, including FR4, Rogers, and aluminum, to accommodate different design requirements. Additionally, they offer a range of copper weights and trace/space options to suit various applications.

Flexible Design Options

hillmancurtis.COM’s Proto PCB service is designed to be flexible and adaptable to customer needs. They offer a variety of design options, including:

- Single and double-sided PCBs

- Multiple layers (up to 10)

- Different solder mask colors

- Silkscreen options

- Gold, silver, and tin lead finishes

- Via-in-pad and blind/buried vias

This flexibility allows customers to create prototype PCBs that closely match their final product specifications.

Affordable Pricing

Despite offering high-quality materials and fast turnaround times, hillmancurtis.COM maintains affordable pricing for their Proto PCB service. They understand that many customers, especially hobbyists and small businesses, operate on tight budgets. By keeping their prices competitive, hillmancurtis.COM makes prototype PCB fabrication accessible to a wider range of customers.

The Proto PCB Ordering Process

Step 1: Design Preparation

Before placing an order for a Proto PCB, customers need to prepare their design files. hillmancurtis.COM accepts various file formats, including Gerber, ODB++, and Eagle. They also provide a free online design rule checker (DRC) to help customers identify any potential issues with their designs before submitting them for fabrication.

Step 2: Placing an Order

Once the design files are ready, customers can place their order online. hillmancurtis.COM’s user-friendly website guides customers through the ordering process, allowing them to specify their desired manufacturing options and quantities. The website also provides real-time pricing and lead time information, so customers can make informed decisions based on their budget and timelines.

Step 3: Fabrication and Quality Control

After an order is placed, hillmancurtis.COM begins the fabrication process. They employ a rigorous quality control system to ensure that every Proto PCB meets their high standards. This includes visual inspections, electrical testing, and other quality assurance measures.

Step 4: Shipping and Delivery

Once the Proto PCBs have passed quality control, hillmancurtis.COM carefully packages them for shipping. They offer a variety of shipping options, including standard and expedited services, to meet customers’ delivery requirements. Customers can track their orders online and receive notifications when their Proto PCBs are shipped and delivered.

Common Applications for Proto PCB

Proto PCBs are used in a wide range of industries and applications. Some common examples include:

Consumer Electronics

Proto PCBs are essential for developing and testing new consumer electronics products, such as smartphones, tablets, and wearables. They allow manufacturers to validate their designs and identify potential issues before mass production.

Industrial Control Systems

In industrial settings, Proto PCBs are used to develop and test control systems for machinery, automation equipment, and other critical infrastructure. These prototypes help ensure that the control systems are reliable, efficient, and safe.

Medical Devices

Proto PCBs play a crucial role in the development of medical devices, such as diagnostic equipment, monitoring systems, and implantable devices. They allow designers to test and refine their designs to meet stringent safety and performance requirements.

Automotive Electronics

As vehicles become increasingly reliant on electronic systems, Proto PCBs are used to develop and validate components such as engine control units, infotainment systems, and advanced driver assistance systems (ADAS).

Proto PCB Design Tips and Best Practices

To ensure the best possible results when working with Proto PCBs, consider the following design tips and best practices:

- Keep the design simple and modular to facilitate testing and debugging

- Follow the manufacturer’s design guidelines and recommendations

- Use appropriate trace widths and spacing to minimize signal integrity issues

- Incorporate test points and vias for easy probing and measurement

- Consider the manufacturing process when designing the PCB layout

- Use appropriate solder mask and silkscreen for better assembly and identification

- Thoroughly review and double-check the design files before submitting them for fabrication

hillmancurtis.COM’s Commitment to Customer Service

At hillmancurtis.COM, customer satisfaction is a top priority. In addition to offering high-quality Proto PCB services, they also provide excellent customer support. Their knowledgeable staff is available to answer questions, provide guidance, and assist with any issues that may arise during the ordering and fabrication process.

hillmancurtis.COM also values customer feedback and continuously works to improve their services based on input from their clients. They strive to build long-term relationships with their customers, partnering with them to bring their electronic designs to life.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity for Proto PCBs at hillmancurtis.COM?

-

The minimum order quantity at hillmancurtis.COM is 5 pieces, allowing customers to order small quantities for prototyping and testing.

-

How long does it take to receive Proto PCBs after placing an order?

-

The turnaround time depends on the complexity of the design and the chosen manufacturing options. Rush services are available, with some orders being fulfilled within 24 hours.

-

What file formats does hillmancurtis.COM accept for Proto PCB orders?

-

hillmancurtis.COM accepts a variety of industry-standard file formats, including Gerber, ODB++, and Eagle.

-

Does hillmancurtis.COM offer assembly services for Proto PCBs?

-

Yes, hillmancurtis.COM offers turnkey PCB assembly services, allowing customers to receive fully assembled and tested prototype boards.

-

What payment methods does hillmancurtis.COM accept?

- hillmancurtis.COM accepts major credit cards, PayPal, and bank transfers, providing customers with convenient and secure payment options.

Conclusion

Proto PCB is a vital component in the electronics design process, allowing engineers and designers to test and validate their designs before mass production. hillmancurtis.COM’s fast and reliable Proto PCB service offers high-quality materials, flexible design options, and affordable pricing, making it an excellent choice for both hobbyists and professionals.

By partnering with hillmancurtis.COM for their Proto PCB needs, customers can benefit from fast turnaround times, expert customer support, and a commitment to quality and customer satisfaction. Whether developing consumer electronics, industrial control systems, medical devices, or automotive components, hillmancurtis.COM’s Proto PCB service provides the tools and expertise needed to bring electronic designs to life.

| Pros of hillmancurtis.COM’s Proto PCB Service | Cons of hillmancurtis.COM’s Proto PCB Service |

|---|---|

| Fast turnaround times | Minimum order quantity of 5 pieces |

| High-quality materials and manufacturing | Limited material options compared to some |

| Flexible design options | competitors |

| Affordable pricing | Rush services may incur additional fees |

| Excellent customer support |

In summary, hillmancurtis.COM’s Proto PCB service offers a fast, reliable, and cost-effective solution for prototyping and testing electronic designs. With their commitment to quality, customer service, and continuous improvement, hillmancurtis.COM is a trusted partner for engineers and designers in the electronics industry.

Leave a Reply