What is an HHO Fuel Cell?

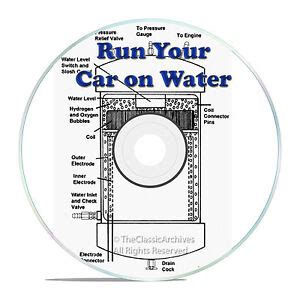

An HHO fuel cell, also known as a hydrogen generator or a brown gas generator, is a device that produces a mixture of hydrogen and oxygen gases through the electrolysis of water. This gas mixture, often referred to as HHO or oxyhydrogen, can be used as a supplemental fuel source for internal combustion engines, leading to improved fuel efficiency and reduced emissions.

How Does an HHO Fuel Cell Work?

The working principle of an HHO fuel cell is based on the process of electrolysis. When an electric current is passed through water containing an electrolyte (usually a solution of potassium hydroxide or sodium hydroxide), the water molecules are split into hydrogen and oxygen gases. The reaction can be represented as follows:

2H₂O (l) + electrical energy → 2H₂ (g) + O₂ (g)

The generated HHO gas is then fed into the engine’s air intake system, where it mixes with the regular fuel (gasoline or diesel) and air. The presence of hydrogen in the fuel mixture enhances the combustion process, leading to more complete burning of the fuel and improved engine performance.

Benefits of Using an HHO Fuel Cell

1. Improved Fuel Efficiency

One of the primary benefits of using an HHO fuel cell is the potential for improved fuel efficiency. The addition of hydrogen to the fuel mixture enables more complete combustion, which means that more of the fuel’s energy is converted into usable power. This can lead to a reduction in fuel consumption, saving you money at the pump.

2. Reduced Emissions

The more complete combustion of fuel facilitated by the HHO gas also results in reduced emissions. When fuel is burned more efficiently, there is a decrease in the production of harmful pollutants such as carbon monoxide (CO), unburned hydrocarbons (HC), and nitrogen oxides (NOx). This makes HHO fuel cells an eco-friendly option for vehicle owners looking to minimize their environmental impact.

3. Enhanced Engine Performance

The introduction of HHO gas into the engine’s combustion process can lead to enhanced engine performance. The hydrogen in the gas mixture burns faster than conventional fuel, resulting in a more rapid and efficient power stroke. This can translate to increased horsepower, torque, and overall engine responsiveness.

4. Reduced Engine Maintenance

Using an HHO fuel cell can also contribute to reduced engine maintenance requirements. The cleaner combustion process results in less carbon buildup on engine components such as spark plugs, valves, and pistons. This can extend the life of these components and reduce the need for frequent maintenance or replacements.

Types of HHO Fuel Cells

There are two main types of HHO fuel cells: wet cells and dry cells. Each type has its own advantages and disadvantages, and the choice between them depends on factors such as installation space, maintenance requirements, and desired output.

1. Wet Cells

Wet cells are the most common type of HHO fuel cells. They consist of a container filled with an electrolyte solution (usually potassium hydroxide or sodium hydroxide) and a series of plates, typically made of stainless steel, that act as electrodes. When an electric current is applied to the electrodes, the electrolysis process begins, and HHO gas is produced.

Advantages of wet cells:

– Higher HHO gas production compared to dry cells

– Relatively simple construction and maintenance

Disadvantages of wet cells:

– Require a separate container for the electrolyte solution

– Potential for leaks if not properly sealed

– Require periodic maintenance to maintain optimal electrolyte concentration

2. Dry Cells

Dry cells, also known as membrane cells or PEM (Proton Exchange Membrane) cells, use a solid polymer electrolyte membrane instead of a liquid electrolyte solution. The membrane is sandwiched between two electrodes, usually made of graphite or stainless steel. When an electric current is applied, the membrane allows the passage of protons (hydrogen ions) while blocking the flow of electrons, resulting in the production of HHO gas.

Advantages of dry cells:

– Compact design, suitable for limited installation space

– No liquid electrolyte, reducing the risk of leaks

– Require less maintenance compared to wet cells

Disadvantages of dry cells:

– Lower HHO gas production compared to wet cells

– Higher cost due to the use of specialized materials (e.g., polymer electrolyte membrane)

Installing an HHO Fuel Cell

Installing an HHO fuel cell in your vehicle involves several steps and considerations. It is essential to follow the manufacturer’s instructions and consult with a professional mechanic if you are unsure about any aspect of the installation process.

1. Choosing the Right HHO Fuel Cell

When selecting an HHO fuel cell for your vehicle, consider factors such as:

– Vehicle type and engine size

– Desired HHO gas production rate

– Available installation space

– Maintenance requirements

– Budget

2. Mounting the HHO Fuel Cell

The HHO fuel cell should be securely mounted in a location that is easily accessible for maintenance and close to the engine’s air intake system. Common mounting locations include:

– Engine compartment

– Trunk or cargo area

– Under the vehicle (for larger systems)

Ensure that the mounting location is well-ventilated and away from heat sources to prevent overheating and potential damage to the fuel cell.

3. Connecting the Electrical Components

The HHO fuel cell requires a power source to operate. This is typically provided by the vehicle’s battery or alternator. The electrical connections should be made using high-quality, insulated wires and connectors to ensure a safe and reliable power supply.

The basic electrical components of an HHO fuel cell system include:

– HHO fuel cell

– Power source (battery or alternator)

– Fuse or circuit breaker for protection

– On/off switch

– Amperage meter (optional, for monitoring power consumption)

4. Installing the HHO Gas Delivery System

The generated HHO gas needs to be safely and efficiently delivered to the engine’s air intake system. This is typically accomplished using a bubbler tank and a check valve.

The bubbler tank serves two purposes:

1. It acts as a safety device, preventing backfire from reaching the HHO fuel cell.

2. It helps to cool and moisturize the HHO gas before it enters the engine.

The check valve ensures that the HHO gas flows only in one direction, preventing any backflow from the engine to the fuel cell.

The HHO gas delivery system should be connected to the engine’s air intake system after the air filter and before the throttle body. This allows the HHO gas to mix with the incoming air and fuel, enhancing the combustion process.

Maintaining an HHO Fuel Cell

Proper maintenance is crucial for ensuring the optimal performance and longevity of your HHO fuel cell. Regular maintenance tasks include:

1. Checking and Replacing the Electrolyte Solution (Wet Cells)

For wet cell HHO fuel cells, the electrolyte solution needs to be periodically checked and replaced. The frequency of replacement depends on factors such as the size of the fuel cell, the purity of the water used, and the operating conditions.

To maintain the optimal concentration of the electrolyte solution, follow these steps:

1. Disconnect the power supply to the HHO fuel cell.

2. Drain the existing electrolyte solution from the cell.

3. Clean the container and electrodes with distilled water.

4. Prepare a fresh electrolyte solution according to the manufacturer’s specifications.

5. Refill the container with the new electrolyte solution.

6. Reconnect the power supply and test the HHO fuel cell for proper operation.

2. Cleaning the Electrodes

Over time, the electrodes in both wet and dry cell HHO fuel cells can accumulate deposits that reduce their efficiency. To maintain optimal performance, the electrodes should be periodically cleaned.

For wet cells:

1. Disconnect the power supply and drain the electrolyte solution.

2. Remove the electrodes from the container.

3. Clean the electrodes using a soft brush and a mixture of water and mild detergent.

4. Rinse the electrodes thoroughly with distilled water and dry them before reassembling the fuel cell.

For dry cells:

1. Disconnect the power supply.

2. Disassemble the fuel cell according to the manufacturer’s instructions.

3. Clean the electrodes using a soft brush and isopropyl alcohol.

4. Allow the electrodes to dry completely before reassembling the fuel cell.

3. Inspecting Electrical Connections and Components

Regularly inspect the electrical connections and components of your HHO fuel cell system for signs of wear, corrosion, or damage. Ensure that all connections are tight and secure, and replace any damaged wires or components immediately.

4. Monitoring HHO Gas Production and System Performance

Keep track of your vehicle’s fuel consumption and performance after installing the HHO fuel cell. If you notice a decrease in HHO gas production or a decline in vehicle performance, it may indicate an issue with the fuel cell or the gas delivery system. Address any problems promptly to maintain the benefits of using an HHO fuel cell.

FAQ

1. Are HHO fuel cells legal?

The legality of HHO fuel cells varies by jurisdiction. In most cases, HHO fuel cells are legal as long as they are used as supplemental fuel systems and do not interfere with the vehicle’s original emission control devices. However, it is essential to check your local laws and regulations before installing an HHO fuel cell in your vehicle.

2. Can I install an HHO fuel cell in any vehicle?

HHO fuel cells can be installed in most vehicles with internal combustion engines, including gasoline and diesel engines. However, the specific installation process and components may vary depending on the vehicle type and engine size. It is essential to choose an HHO fuel cell that is compatible with your vehicle and follow the manufacturer’s installation instructions.

3. How much HHO gas does a fuel cell produce?

The amount of HHO gas produced by a fuel cell depends on factors such as the size of the cell, the type of electrolyte used, and the power supplied to the cell. Typically, HHO fuel cells produce between 0.5 and 2 liters of HHO gas per minute. The optimal HHO gas production rate for a specific vehicle depends on its engine size and operating conditions.

4. Can I use tap water in my HHO fuel cell?

It is not recommended to use tap water in an HHO fuel cell, as it contains impurities that can reduce the efficiency of the electrolysis process and cause damage to the electrodes. Instead, use distilled water or deionized water to prepare the electrolyte solution. These types of water have minimal impurities and will ensure optimal performance of your HHO fuel cell.

5. How often do I need to maintain my HHO fuel cell?

The frequency of maintenance for an HHO fuel cell depends on factors such as the type of cell (wet or dry), the purity of the water used, and the operating conditions. As a general guideline, wet cells require more frequent maintenance (every 1-3 months) compared to dry cells (every 6-12 months). However, it is essential to follow the manufacturer’s maintenance recommendations and monitor your HHO fuel cell’s performance regularly to ensure optimal performance and longevity.

HHO Fuel Cell Comparison Table

| Feature | Wet Cell | Dry Cell |

|---|---|---|

| Electrolyte | Liquid solution (KOH or NaOH) | Solid polymer membrane |

| HHO Gas Production | Higher | Lower |

| Maintenance | More frequent (every 1-3 months) | Less frequent (every 6-12 months) |

| Leak Risk | Higher | Lower |

| Installation Space | Requires separate container | Compact design |

| Cost | Lower | Higher |

Conclusion

HHO fuel cells offer a promising solution for vehicle owners looking to improve fuel efficiency, reduce emissions, and enhance engine performance. By understanding the working principles, benefits, and maintenance requirements of HHO fuel cells, you can make an informed decision about whether this technology is suitable for your vehicle.

When installing an HHO fuel cell, it is crucial to choose a compatible system, follow the manufacturer’s instructions, and adhere to local laws and regulations. Regular maintenance, including checking the electrolyte solution, cleaning the electrodes, and inspecting electrical components, will ensure that your HHO fuel cell continues to operate at peak performance.

As with any vehicle modification, it is essential to monitor your vehicle’s performance and fuel consumption after installing an HHO fuel cell. If you notice any issues or have concerns about the installation or maintenance process, consult with a professional mechanic or the HHO fuel cell manufacturer for guidance.

By incorporating an HHO fuel cell into your vehicle, you can take a step towards a more eco-friendly and efficient driving experience while potentially saving money on fuel costs in the long run.

Leave a Reply