What is PCB Crosstalk?

PCB crosstalk is a phenomenon that occurs when signals from one circuit or trace unintentionally affect signals in another nearby circuit or trace on a printed circuit board (PCB). This unwanted interaction between signals can lead to signal integrity issues, such as signal distortion, noise, and interference, which can ultimately impact the performance and reliability of the electronic device.

Crosstalk happens due to electromagnetic coupling between adjacent traces or circuits. There are two main types of crosstalk:

-

Inductive Crosstalk: This type of crosstalk occurs when changing currents in one trace induce voltages in a neighboring trace through mutual inductance.

-

Capacitive Crosstalk: This type of crosstalk happens when voltages on one trace induce currents in a neighboring trace through mutual capacitance.

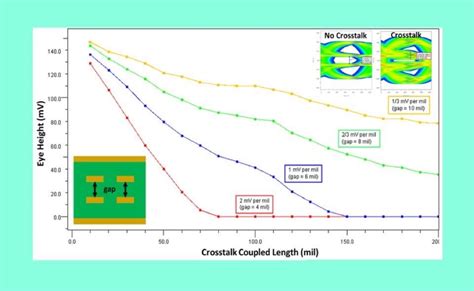

The severity of crosstalk depends on various factors, including:

- The proximity of the traces or circuits

- The length of the parallel run between traces

- The signal rise and fall times

- The characteristic impedance of the traces

- The dielectric constant of the PCB material

Why is PCB Crosstalk a Concern?

PCB crosstalk can cause several issues that negatively impact the performance and reliability of electronic devices:

-

Signal Integrity Degradation: Crosstalk can distort signals, introduce noise, and cause interference, leading to reduced signal integrity. This can result in data errors, false triggering, and other malfunctions.

-

Timing Issues: Crosstalk can cause delays or skews in signal propagation, which can lead to timing violations and synchronization problems, especially in high-speed digital systems.

-

Electromagnetic Interference (EMI): Crosstalk can contribute to EMI, which can cause the electronic device to interfere with other nearby devices or fail to meet regulatory EMI standards.

-

Reduced Reliability: Crosstalk-induced issues can compromise the overall reliability of the electronic device, leading to increased failure rates and reduced product lifespan.

Techniques to Counter PCB Crosstalk

To minimize the impact of PCB crosstalk, designers can employ various techniques during the PCB layout and design process:

1. Trace Spacing and Routing

One of the most effective ways to reduce crosstalk is to increase the spacing between traces and carefully route them to minimize parallel runs. The following table provides general guidelines for trace spacing based on signal types:

| Signal Type | Minimum Spacing |

|---|---|

| Digital | 3 × trace width |

| Analog | 5 × trace width |

| High-speed | 10 × trace width |

Additionally, designers should:

- Route sensitive traces away from noisy traces

- Avoid long parallel runs between traces

- Use diagonal or 45-degree routing when possible

- Separate analog and digital grounds

2. Grounding and Shielding

Proper grounding and shielding techniques can help reduce crosstalk:

- Use ground planes to provide a low-impedance return path for signals

- Place ground traces between sensitive signal traces to act as shields

- Use guard traces or coplanar waveguides for critical signals

- Implement shield cans or Faraday cages for sensitive circuits

3. Impedance Matching and Termination

Matching the characteristic impedance of traces and properly terminating them can help minimize reflections and crosstalk:

- Use controlled impedance traces for high-speed signals

- Terminate traces with resistors or other components to match the source and load impedances

- Implement series termination for source-end reflections

- Use parallel termination for load-end reflections

4. Signal Rise and Fall Times

Reducing signal rise and fall times can help decrease crosstalk:

- Use slew rate control techniques, such as series resistors or ferrite beads, to slow down fast signal edges

- Choose components with lower output slew rates when possible

- Implement waveform shaping circuits to control signal rise and fall times

5. PCB Material Selection

Choosing appropriate PCB materials can help reduce crosstalk:

- Use PCB materials with lower dielectric constants to reduce capacitive coupling

- Select PCB materials with higher resistivity to minimize conductivity between traces

- Consider using low-loss tangent materials for high-frequency applications

Simulation and Analysis Tools

To identify and mitigate crosstalk issues during the PCB design process, designers can use various simulation and analysis tools:

-

Signal Integrity Simulation: Tools like Hyperlynx, Sigrity, and Mentor Graphics HyperLynx can simulate signal behavior and help identify crosstalk issues early in the design process.

-

Electromagnetic Field Solvers: 3D EM field solvers, such as Ansys HFSS and CST Studio Suite, can accurately model electromagnetic interactions between traces and components, helping designers optimize their layouts for minimal crosstalk.

-

SPICE-based Circuit Simulation: SPICE (Simulation Program with Integrated Circuit Emphasis) tools, like LTspice and PSpice, can simulate circuit behavior and help analyze the impact of crosstalk on signal integrity.

-

Post-layout Analysis: Tools like Cadence Allegro PCB Designer and Altium Designer offer post-layout analysis features that can help identify crosstalk issues and suggest improvements to the PCB layout.

Real-World Examples and Case Studies

Example 1: High-Speed Digital Interface

In a high-speed digital interface, such as USB or PCIe, crosstalk can cause data errors and reduce the overall performance of the system. To mitigate crosstalk, designers can:

- Use differential signaling to cancel out common-mode noise

- Maintain tight spacing between differential pairs

- Implement ground shielding between pairs

- Carefully route traces to minimize parallel runs

- Match trace lengths to ensure proper signal timing

Example 2: Mixed-Signal PCB

In a mixed-signal PCB, where analog and digital circuits coexist, crosstalk can cause noise and interference issues. To counter crosstalk, designers can:

- Physically separate analog and digital sections of the PCB

- Use separate analog and digital ground planes

- Route sensitive analog traces away from noisy digital traces

- Implement filters and shielding to isolate analog and digital signals

- Use appropriate PCB materials to minimize coupling

Frequently Asked Questions (FAQ)

1. What is the difference between inductive and capacitive crosstalk?

Inductive crosstalk occurs when changing currents in one trace induce voltages in a neighboring trace through mutual inductance. Capacitive crosstalk happens when voltages on one trace induce currents in a neighboring trace through mutual capacitance.

2. How does trace spacing affect crosstalk?

Increasing the spacing between traces reduces the electromagnetic coupling between them, thus minimizing crosstalk. The minimum recommended spacing depends on the signal type, with high-speed and sensitive signals requiring greater separation.

3. Can grounding techniques help reduce crosstalk?

Yes, proper grounding techniques, such as using ground planes, placing ground traces between sensitive signals, and implementing guard traces or coplanar waveguides, can help reduce crosstalk by providing a low-impedance return path and shielding.

4. What is the role of impedance matching and termination in reducing crosstalk?

Matching the characteristic impedance of traces and properly terminating them helps minimize reflections and ringing, which can contribute to crosstalk. Series and parallel termination techniques can be used to match source and load impedances, respectively.

5. How can simulation and analysis tools help in identifying and mitigating crosstalk issues?

Simulation and analysis tools, such as signal integrity simulators, electromagnetic field solvers, and SPICE-based Circuit Simulators, can help designers identify crosstalk issues early in the design process. These tools can simulate signal behavior, model electromagnetic interactions, and suggest improvements to the PCB layout to minimize crosstalk.

Conclusion

PCB crosstalk is a critical issue that can negatively impact the performance and reliability of electronic devices. By understanding the causes and effects of crosstalk, designers can employ various techniques to minimize its impact, such as optimizing trace spacing and routing, implementing proper grounding and shielding, matching impedances and terminating traces, controlling signal rise and fall times, and selecting appropriate PCB materials.

Additionally, using simulation and analysis tools can help identify and mitigate crosstalk issues early in the design process, saving time and resources in the long run. By following best practices and utilizing the available tools and techniques, designers can effectively counter PCB crosstalk and ensure the optimal performance and reliability of their electronic devices.

Leave a Reply