Introduction to PWM Inverters

A PWM (Pulse Width Modulation) inverter is a type of power inverter that converts direct current (DC) to alternating current (AC) using a switching technique called pulse width modulation. PWM inverters are widely used in various applications, including solar power systems, uninterruptible power supplies (UPS), and motor speed control.

PWM inverters offer several advantages over other types of inverters, such as:

- High efficiency

- Low harmonic distortion

- Ability to handle a wide range of loads

- Compact size and lightweight design

- Affordable cost

In this article, we will explore the working principle of PWM inverters, their applications, advantages, and disadvantages, and how they are ideal for distinct loads connected.

How PWM Inverters Work

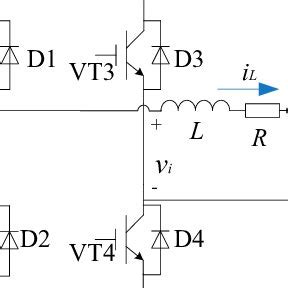

A PWM inverter works by converting DC power into AC power using a series of high-frequency switches, typically MOSFETs (Metal Oxide Semiconductor Field Effect Transistors) or IGBTs (Insulated Gate Bipolar Transistors). The switching frequency is usually in the range of a few kilohertz to several hundred kilohertz.

The PWM technique involves varying the width of the pulses to control the output voltage and frequency. By changing the pulse width, the average voltage can be adjusted to match the desired AC waveform. The longer the pulse width, the higher the output voltage, and vice versa.

The basic components of a PWM inverter include:

- DC input: The DC power source, such as a battery or solar panel, provides the input power to the inverter.

- PWM controller: The PWM controller generates the switching signals for the power switches based on the desired output voltage and frequency.

- Power switches: The power switches, usually MOSFETs or IGBTs, turn on and off rapidly to convert the DC input into a series of high-frequency pulses.

- Output filter: The output filter, consisting of inductors and capacitors, smooths out the high-frequency pulses into a sinusoidal AC waveform.

- Transformer (optional): Some PWM inverters use a transformer to step up or step down the output voltage to match the desired level.

Advantages of PWM Inverters

PWM inverters offer several advantages over other types of inverters, making them ideal for various applications:

High Efficiency

PWM inverters are highly efficient, typically achieving efficiency levels of 90% or higher. This high efficiency is due to the use of high-frequency switching, which minimizes power losses in the inverter components. As a result, PWM inverters generate less heat and require smaller heat sinks, making them more compact and lightweight.

Low Harmonic Distortion

PWM inverters produce AC waveforms with low harmonic distortion, typically less than 3% total harmonic distortion (THD). This low distortion is achieved by using high-frequency switching and output filters to smooth out the waveform. Low harmonic distortion is essential for sensitive electronic equipment and ensures that the connected loads operate efficiently and reliably.

Wide Load Handling Capability

PWM inverters can handle a wide range of loads, including resistive, inductive, and capacitive loads. They can also handle non-linear loads, such as switching power supplies and electronic ballasts, which draw current in short pulses rather than sinusoidal waveforms. This versatility makes PWM inverters suitable for a variety of applications, from powering household appliances to industrial equipment.

Compact Size and Lightweight Design

Due to their high efficiency and low heat generation, PWM inverters can be designed in compact and lightweight packages. This makes them ideal for portable and space-constrained applications, such as solar power systems for RVs and boats, or backup power supplies for computers and other sensitive equipment.

Affordable Cost

PWM inverters are generally more affordable than other types of inverters, such as true sine wave inverters, due to their simpler design and lower component count. This makes them an attractive option for cost-sensitive applications and budget-conscious users.

Applications of PWM Inverters

PWM inverters are used in a wide range of applications, including:

Solar Power Systems

PWM inverters are commonly used in solar power systems to convert the DC power generated by solar panels into AC power for household and commercial use. They are particularly suitable for off-grid solar systems, where the inverter must handle a variety of loads and provide reliable power output.

Uninterruptible Power Supplies (UPS)

PWM inverters are used in UPS systems to provide backup power during power outages or fluctuations. They convert the DC power stored in batteries into AC power to keep critical equipment, such as computers, servers, and medical devices, running smoothly.

Motor Speed Control

PWM inverters are used in motor speed control applications, such as variable frequency drives (VFDs) for industrial motors and electric vehicle drives. By varying the frequency and voltage of the AC output, PWM inverters can control the speed and torque of the connected motors, improving efficiency and performance.

Home Appliances

PWM inverters are used in various home appliances, such as air conditioners, refrigerators, and washing machines, to convert DC power from batteries or solar panels into AC power. They provide a cost-effective and efficient solution for off-grid or backup power applications.

Disadvantages of PWM Inverters

While PWM inverters offer many advantages, they also have some limitations and disadvantages:

Non-Sinusoidal Output Waveform

PWM inverters produce a modified sine wave output, which is not a perfect sinusoidal waveform. While this waveform is suitable for most loads, some sensitive electronic equipment may not operate correctly or efficiently with a modified sine wave input. In such cases, a true sine wave inverter may be required.

Electromagnetic Interference (EMI)

The high-frequency switching in PWM inverters can generate electromagnetic interference (EMI), which can affect nearby electronic devices. To minimize EMI, PWM inverters must be designed with proper shielding and filtering techniques, which can add to the cost and complexity of the inverter.

Limited Surge Capacity

PWM inverters have a limited surge capacity, which is the ability to handle short-term overloads or startup currents from connected loads. If the surge current exceeds the inverter’s capacity, it may trigger the inverter’s protection circuits or damage the inverter components. Users must ensure that the inverter’s surge capacity is sufficient for the intended loads.

Ideal Loads for PWM Inverters

PWM inverters are ideal for a wide range of loads, including:

-

Resistive loads: Resistive loads, such as incandescent light bulbs, electric heaters, and toasters, draw a constant current and have a unity power factor. PWM inverters can efficiently power these loads without any issues.

-

Inductive loads: Inductive loads, such as motors, transformers, and solenoids, have a lagging power factor and draw a higher startup current. PWM inverters can handle these loads effectively, provided that the inverter’s surge capacity is sufficient for the startup current.

-

Capacitive loads: Capacitive loads, such as switching power supplies and electronic ballasts, have a leading power factor and draw current in short pulses. PWM inverters can power these loads efficiently, thanks to their high-frequency switching and output filtering.

-

Non-linear loads: Non-linear loads, such as computers, televisions, and audio equipment, draw current in a non-sinusoidal waveform and can generate harmonics. PWM inverters can power these loads effectively, as long as the total harmonic distortion (THD) is within acceptable limits.

However, PWM inverters may not be suitable for some sensitive electronic equipment that requires a pure sinusoidal waveform, such as medical devices, scientific instruments, and high-end audio equipment. In these cases, a true sine wave inverter may be required to ensure proper operation and performance.

Choosing the Right PWM Inverter

When selecting a PWM inverter for your application, consider the following factors:

-

Power rating: Choose an inverter with a power rating that matches or exceeds the total power consumption of the connected loads. Consider both the continuous power rating and the surge power rating to ensure that the inverter can handle the startup currents of inductive loads.

-

Input voltage: Ensure that the inverter’s input voltage range is compatible with your DC power source, such as a battery bank or solar panel array.

-

Output voltage and frequency: Select an inverter with an output voltage and frequency that matches the requirements of your connected loads. In most cases, a 120V, 60Hz output is suitable for North American applications, while a 230V, 50Hz output is used in many other parts of the world.

-

Efficiency: Choose an inverter with high efficiency to minimize power losses and heat generation. Look for inverters with efficiency ratings of 90% or higher.

-

Protective features: Look for inverters with built-in protective features, such as overload protection, short circuit protection, over-temperature protection, and low battery voltage shutdown. These features help ensure the safety and reliability of the inverter and connected loads.

-

Warranty and support: Choose an inverter from a reputable manufacturer that offers a comprehensive warranty and technical support. This ensures that you can get assistance if any issues arise during installation or operation.

FAQ

1. What is a PWM inverter?

A PWM (Pulse Width Modulation) inverter is a type of power inverter that converts direct current (DC) to alternating current (AC) using a switching technique called pulse width modulation. PWM inverters are widely used in various applications, such as solar power systems, UPS, and motor speed control.

2. What are the advantages of PWM inverters?

The advantages of PWM inverters include high efficiency, low harmonic distortion, wide load handling capability, compact size and lightweight design, and affordable cost.

3. Can PWM inverters handle all types of loads?

PWM inverters can handle a wide range of loads, including resistive, inductive, capacitive, and non-linear loads. However, some sensitive electronic equipment that requires a pure sinusoidal waveform may not operate correctly with a PWM inverter, and a true sine wave inverter may be required.

4. What should I consider when choosing a PWM inverter?

When choosing a PWM inverter, consider factors such as power rating, input voltage, output voltage and frequency, efficiency, protective features, and warranty and support. Ensure that the inverter’s specifications match the requirements of your application and connected loads.

5. Are PWM inverters suitable for off-grid solar power systems?

Yes, PWM inverters are commonly used in off-grid solar power systems to convert the DC power generated by solar panels into AC power for household and commercial use. They are particularly suitable for these applications due to their high efficiency, wide load handling capability, and affordable cost.

Conclusion

PWM inverters are a versatile and efficient solution for converting DC power to AC power in a wide range of applications. Their high efficiency, low harmonic distortion, wide load handling capability, compact size, and affordable cost make them ideal for powering distinct loads in solar power systems, UPS, motor speed control, and home appliances.

When selecting a PWM inverter, it is essential to consider factors such as power rating, input and output specifications, efficiency, protective features, and warranty and support. By choosing the right inverter for your application and ensuring proper installation and maintenance, you can enjoy reliable and efficient power conversion for your connected loads.

As renewable energy sources and battery storage technologies continue to advance, PWM inverters will play an increasingly important role in enabling the adoption of clean and sustainable power solutions. By understanding the working principle, advantages, and applications of PWM inverters, you can make informed decisions when designing or upgrading your power systems.

Leave a Reply