Understanding PCB Fabrication

Before diving into the criteria for selecting a PCB fabrication service, let’s briefly discuss what PCB fabrication entails.

What is PCB Fabrication?

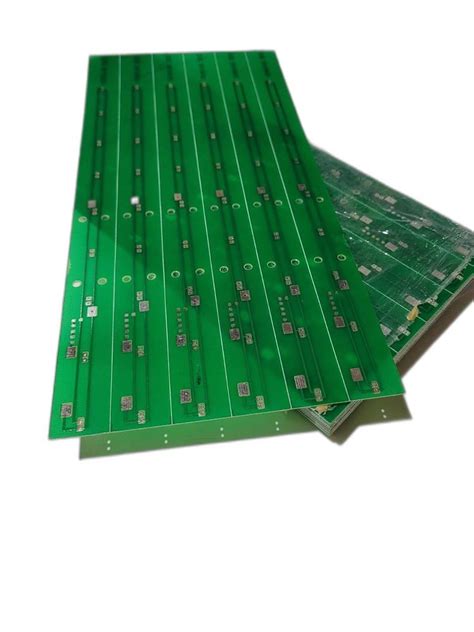

PCB fabrication is the process of creating printed circuit boards that mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate.

PCB Fabrication Process

The PCB fabrication process typically involves the following steps:

- Design: Creating the PCB layout using specialized software

- Printing: Transferring the design onto the copper-clad board

- Etching: Removing unwanted copper to create conductive tracks

- Drilling: Making holes for component placement

- Plating: Applying a thin layer of metal to improve conductivity and prevent oxidation

- Silkscreen: Adding text and symbols for easy identification

- Surface Finish: Applying a protective coating to enhance solderability and durability

- Electrical Testing: Verifying the functionality of the fabricated PCB

Factors to Consider When Choosing a PCB Fabrication Service

Now that we have a basic understanding of PCB fabrication let’s explore the key factors to consider when selecting a reliable PCB fabrication service.

1. Quality and Certifications

One of the most important aspects to consider when choosing a PCB fabrication service is the quality of their products. Look for a manufacturer that adheres to industry standards and has the necessary certifications, such as:

- ISO 9001: Quality Management System

- UL (Underwriters Laboratories): Safety Certification

- IPC (Association Connecting Electronics Industries) Standards: Ensures consistency and reliability

A reputable PCB fabrication service should be able to provide documentation of their certifications and quality control processes.

2. Manufacturing Capabilities

Different PCB fabrication services offer varying manufacturing capabilities. Consider the following aspects when evaluating a manufacturer’s capabilities:

- PCB types: Single-sided, double-sided, or multi-layered boards

- Material Options: FR-4, high-frequency materials, flexible substrates, etc.

- Minimum Feature Sizes: Line width, spacing, and hole diameter

- Surface Finishes: HASL, lead-free HASL, ENIG, OSP, etc.

- Turnaround Time: How quickly they can fabricate and deliver your PCBs

Choose a PCB fabrication service that can accommodate your specific requirements and has experience in manufacturing boards similar to your design.

3. Customer Support and Communication

Effective communication is key to a successful partnership with your PCB fabrication service. Consider the following aspects when evaluating their customer support:

- Responsiveness: How quickly they respond to your inquiries and concerns

- Technical Support: Availability of knowledgeable staff to assist with design and manufacturing issues

- Language Barriers: Ability to communicate effectively in your preferred language

- File Handling: Ease of transferring design files and receiving feedback

A reliable PCB fabrication service should be proactive in their communication and provide clear guidelines for file submission and project management.

4. Pricing and Value

While cost is an important consideration, it should not be the sole deciding factor when choosing a PCB fabrication service. Consider the following aspects when evaluating pricing and value:

- Cost per Unit: Compare prices from multiple manufacturers for your specific requirements

- Minimum Order Quantity (MOQ): Some manufacturers may have higher MOQs, which can impact your overall cost

- Additional Services: Design support, assembly, testing, and packaging options

- Shipping Costs: Consider the manufacturer’s location and shipping options to minimize transit costs and time

Look for a PCB fabrication service that offers competitive pricing while maintaining high-quality standards and value-added services.

5. Reputation and Reviews

Before making a final decision, research the reputation and reviews of the PCB fabrication services you are considering. Take into account the following sources:

- Online Reviews: Check websites like TrustPilot, Google Reviews, and industry forums for customer feedback

- Referrals: Ask for recommendations from colleagues, suppliers, or online communities

- Case Studies: Look for success stories or case studies showcasing the manufacturer’s capabilities

- Industry Awards: Recognition from respected organizations can indicate a manufacturer’s commitment to quality and innovation

A reputable PCB fabrication service should have a track record of satisfied customers and a strong presence in the industry.

Comparing PCB Fabrication Services

To help you make an informed decision, let’s compare a few hypothetical PCB fabrication services based on the factors we discussed earlier:

| Manufacturer | Quality & Certifications | Manufacturing Capabilities | Customer Support | Pricing & Value | Reputation |

|---|---|---|---|---|---|

| ABC Circuits | ISO 9001, UL, IPC Class 2 | Single & Double-sided, FR-4, HASL | Responsive, Multi-language | Competitive, Low MOQ | Excellent |

| XYZ Boards | ISO 9001 | Single-sided, FR-4, HASL | Limited, Language Barriers | Low Cost, High MOQ | Average |

| PQR Tech | ISO 9001, UL, IPC Class 3 | Multi-layer, RF Materials, ENIG | Responsive, Technical Support | Premium, Value-added Services | Good |

Based on this comparison, ABC Circuits appears to be a reliable choice for most standard PCB fabrication needs, while PQR Tech may be more suitable for complex, high-performance designs.

PCB Fabrication Service FAQs

-

Q: What is the typical turnaround time for PCB fabrication?

A: The turnaround time for PCB fabrication varies depending on the manufacturer and the complexity of your design. Standard lead times range from 5 to 15 business days, while expedited services can deliver PCBs in as little as 24-48 hours. -

Q: Can I get a prototype before committing to a full production run?

A: Yes, most PCB fabrication services offer prototyping options. This allows you to test and validate your design before investing in a larger production run. -

Q: What files do I need to provide for PCB fabrication?

A: Typically, you will need to provide Gerber files (RS-274X format), drill files (Excellon format), and a bill of materials (BOM) for your PCB design. Some manufacturers may also accept native CAD files from popular PCB design software. -

Q: How can I ensure my PCB design is manufacturable?

A: To ensure your PCB design is manufacturable, follow the manufacturer’s design guidelines, which include minimum feature sizes, clearances, and drill sizes. Most PCB fabrication services offer design for manufacturability (DFM) checks to identify potential issues before production. -

Q: What should I do if I receive PCBs that do not meet my specifications?

A: If you receive PCBs that do not meet your specifications, contact the manufacturer’s customer support immediately. A reliable PCB fabrication service should have a clear quality control and return policy in place to address such issues and provide appropriate solutions, such as replacements or refunds.

Conclusion

Choosing a reliable PCB fabrication service is essential for the success of your electronic product. By considering factors such as quality, manufacturing capabilities, customer support, pricing, and reputation, you can make an informed decision that meets your specific requirements.

Remember to prioritize quality and reliability over cost alone, as the long-term success of your product depends on the performance and durability of your PCBs. With the right PCB fabrication partner, you can bring your electronic designs to life and stay competitive in today’s fast-paced market.

Leave a Reply