What is a Board Stiffener?

A board stiffener is a device used to add rigidity and support to printed circuit boards (PCBs) or other thin, flat materials. It is typically made of a strong, lightweight material such as aluminum or steel and is attached to the back of the board using adhesive or mechanical fasteners. The purpose of a board stiffener is to prevent the board from flexing or warping due to mechanical stress, thermal expansion, or other factors that can cause damage or affect the performance of the components mounted on the board.

Types of Board Stiffeners

There are several types of board stiffeners available, each with its own unique characteristics and benefits. Some common types include:

-

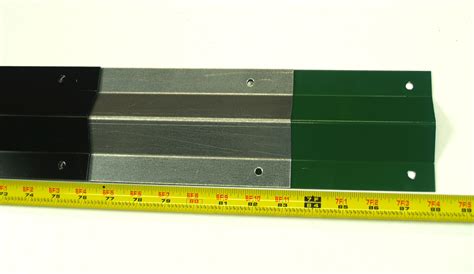

Flat Plate Stiffeners: These are simple, flat pieces of metal that are attached to the back of the board. They provide basic support and rigidity but may not be suitable for boards with complex shapes or high stress requirements.

-

Ribbed Stiffeners: These stiffeners feature raised ribs or channels that run across the surface of the metal plate. The ribs add extra strength and stiffness to the board while also providing channels for air flow and heat dissipation.

-

Frame Stiffeners: These stiffeners consist of a metal frame that surrounds the perimeter of the board. The frame provides support and protection for the edges of the board and can also serve as a mounting point for connectors, heat sinks, or other components.

-

Custom Stiffeners: For boards with unique shapes or requirements, custom stiffeners can be designed and manufactured to provide optimal support and performance. These may include features such as cutouts, mounting holes, or specialized materials.

| Type | Advantages | Disadvantages |

|---|---|---|

| Flat Plate | Simple design, low cost | Limited stiffness, may not suit complex shapes |

| Ribbed | Increased stiffness, improved heat dissipation | Higher cost than flat plate, may require custom design |

| Frame | Edge protection, mounting points for components | Higher cost and weight than other types |

| Custom | Tailored to specific board requirements | Highest cost, longer lead times for manufacturing |

Benefits of Using a Board Stiffener

Using a board stiffener can provide several benefits for PCB designers and manufacturers:

-

Improved Reliability: By preventing the board from flexing or warping, a stiffener can help to reduce stress on components and solder joints, leading to improved reliability and longer product life.

-

Enhanced Performance: A stable, rigid board can help to maintain proper alignment and spacing between components, which can improve signal integrity and overall performance.

-

Better Heat Dissipation: Some types of stiffeners, such as ribbed or custom designs, can provide channels for air flow and heat dissipation, helping to keep components cool and prevent thermal damage.

-

Increased Durability: A board with a stiffener is more resistant to mechanical stress and impact, making it less likely to be damaged during handling, shipping, or use.

-

Space Savings: By allowing for a thinner, lighter board design, a stiffener can help to reduce the overall size and weight of the final product, which can be important in applications where space is limited.

How to Choose the Right Board Stiffener

When selecting a board stiffener for your project, there are several factors to consider:

-

Board Size and Shape: The size and shape of your PCB will determine the type and size of stiffener that is most appropriate. Flat plate stiffeners may be suitable for simple rectangular boards, while more complex shapes may require a custom or frame stiffener.

-

Component Placement: Consider the location and height of components on the board, as well as any connectors or mounting points that may need to be accommodated by the stiffener design.

-

Environmental Factors: Think about the operating environment of your product, including temperature, humidity, and vibration. This will help you choose a stiffener material and design that can withstand these conditions.

-

Cost and Lead Time: Different types of stiffeners vary in cost and manufacturing time, so consider your budget and project schedule when making a selection.

-

Manufacturing Process: The type of stiffener you choose may impact the manufacturing process for your board. For example, a frame stiffener may require additional steps for attachment and alignment compared to a flat plate stiffener.

Installing a Board Stiffener

Once you have selected the appropriate board stiffener for your project, the next step is to install it on your PCB. The specific installation process will vary depending on the type of stiffener and the attachment method used, but generally involves the following steps:

-

Surface Preparation: Clean the surface of the PCB and the stiffener to remove any dirt, grease, or debris that could interfere with adhesion.

-

Alignment: Position the stiffener on the back of the board, ensuring that it is properly aligned with any mounting holes or other features.

-

Attachment: Secure the stiffener to the board using the chosen attachment method, such as adhesive, screws, or rivets. If using adhesive, follow the manufacturer’s instructions for application and curing time.

-

Inspection: After installation, visually inspect the board and stiffener to ensure that it is securely attached and properly aligned.

Frequently Asked Questions (FAQ)

-

Q: Can I use a board stiffener on any type of PCB?

A: Board stiffeners can be used on most types of PCBs, including rigid, flexible, and rigid-flex boards. However, the specific type and design of the stiffener may need to be adapted to suit the particular requirements of your board. -

Q: How do I know if my PCB needs a board stiffener?

A: If your board is experiencing issues with flexing, warping, or mechanical stress, or if you are concerned about the reliability or performance of your components, a board stiffener may be a good solution. Consult with your PCB designer or manufacturer to determine if a stiffener is appropriate for your project. -

Q: Can I install a board stiffener myself, or do I need professional assistance?

A: In most cases, a board stiffener can be installed by a skilled technician or engineer with the appropriate tools and equipment. However, if you are unsure about the process or if your board has complex requirements, it may be best to seek professional assistance from a PCB Assembly provider. -

Q: How much does a board stiffener cost?

A: The cost of a board stiffener can vary widely depending on the type, size, and complexity of the design, as well as the material and manufacturing process used. Simple flat plate stiffeners may cost just a few dollars, while custom designs can be significantly more expensive. Consult with your PCB manufacturer or stiffener provider for specific pricing information. -

Q: Can a board stiffener be removed or replaced if needed?

A: In most cases, a board stiffener is considered a permanent part of the PCB assembly and is not designed to be removed or replaced. However, if a stiffener becomes damaged or needs to be modified, it may be possible to carefully remove it and install a new one, depending on the attachment method used. Consult with a PCB repair specialist for guidance on stiffener removal and replacement.

Conclusion

Board stiffeners are an important tool for PCB designers and manufacturers looking to improve the reliability, performance, and durability of their products. By providing additional support and rigidity to the board, stiffeners can help to prevent flexing, warping, and other issues that can lead to component failure or reduced functionality. When selecting a board stiffener, it is important to consider factors such as board size and shape, component placement, environmental conditions, cost, and manufacturing process to ensure that you choose the best solution for your specific needs. With proper selection and installation, a board stiffener can be a valuable addition to any PCB design, helping to ensure long-term success and customer satisfaction.

Leave a Reply