What is Flexible Flat Cable?

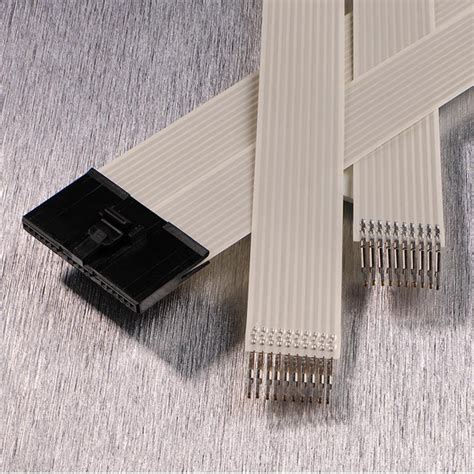

Flexible flat cable is a type of electrical cable that consists of multiple conductors that are arranged in a flat, parallel configuration. The conductors are typically made of copper or other conductive materials, and are insulated with a thin layer of plastic or other insulating material. The insulation is typically made of a flexible material such as polyester or polyimide, which allows the cable to bend and flex without damaging the conductors.

FFC is available in a variety of configurations, including single-sided and double-sided designs. Single-sided FFC has conductors on only one side of the insulation, while double-sided FFC has conductors on both sides. Double-sided FFC is often used in applications where a higher density of conductors is required.

Advantages of Flexible Flat Cable

There are several advantages to using flexible flat cable in your designs:

-

Space Savings: FFC is much thinner and more compact than traditional round cables, which allows you to save space in your designs. This is particularly important in applications where space is limited, such as in mobile devices or wearable electronics.

-

Flexibility: As the name suggests, FFC is highly flexible, which allows it to bend and flex without damaging the conductors. This makes it ideal for applications where the cable needs to move or flex repeatedly, such as in hinges or sliding mechanisms.

-

Lightweight: FFC is much lighter than traditional round cables, which can help reduce the overall weight of your product. This is particularly important in applications where weight is a critical factor, such as in aerospace or automotive applications.

-

High Density: FFC can be designed with a high density of conductors, which allows you to transmit more signals or power in a smaller space. This is particularly useful in applications where a large number of signals need to be transmitted, such as in displays or sensors.

-

Cost-Effective: FFC is often more cost-effective than traditional round cables, particularly in high-volume applications. This is because FFC can be manufactured using automated processes, which reduces labor costs and increases efficiency.

How to Use Flexible Flat Cable in Your Designs

Now that we’ve explored the benefits of using flexible flat cable in your designs, let’s take a look at some of the ways you can incorporate it into your products.

Connecting Displays

One of the most common applications for FFC is in connecting displays to other components in electronic devices. FFC is often used to connect LCD or OLED displays to the main circuit board in devices such as smartphones, tablets, and laptops. The thin, flexible nature of FFC allows it to be routed through tight spaces and around corners, which helps to reduce the overall size of the device.

Connecting Sensors

FFC is also commonly used to connect sensors to other components in electronic devices. For example, in a smartphone, FFC may be used to connect the camera module to the main circuit board, or to connect the fingerprint sensor to the processor. The high density of conductors in FFC allows it to transmit large amounts of data quickly and efficiently, which is essential for high-performance sensors.

Connecting Batteries

In many electronic devices, the battery is located in a separate compartment from the main circuit board. FFC can be used to connect the battery to the main circuit board, providing power to the device. The flexible nature of FFC allows it to be routed through tight spaces and around corners, which helps to reduce the overall size of the device.

Connecting Moving Parts

FFC is also commonly used to connect moving parts in electronic devices. For example, in a laptop, FFC may be used to connect the keyboard to the main circuit board, or to connect the touchpad to the processor. The flexibility of FFC allows it to bend and flex as the device is opened and closed, without damaging the conductors.

Connecting Wearable Devices

Wearable devices such as smartwatches and fitness trackers often require a high degree of flexibility in order to be comfortable to wear. FFC can be used to connect the various components in these devices, such as the display, sensors, and battery. The thin, lightweight nature of FFC allows it to be integrated into the device without adding bulk or weight.

Designing with Flexible Flat Cable

When designing with flexible flat cable, there are several factors to consider in order to ensure optimal performance and reliability.

Cable Length

The length of the FFC can have a significant impact on its performance. Longer cables may be more susceptible to signal loss or interference, particularly at high frequencies. It is important to choose a cable length that is appropriate for your application, and to consider the potential impact of cable length on signal integrity.

Cable Thickness

The thickness of the FFC can also impact its performance and reliability. Thicker cables may be more durable and less susceptible to damage, but they may also be less flexible and more difficult to route through tight spaces. Thinner cables may be more flexible and easier to route, but they may be more susceptible to damage or signal loss. It is important to choose a cable thickness that balances these factors based on your specific application.

Conductor Spacing

The spacing between the conductors in the FFC can also impact its performance and reliability. Closer spacing may allow for higher density and more signals to be transmitted, but it may also increase the risk of crosstalk or interference between adjacent conductors. Wider spacing may reduce the risk of crosstalk, but it may also reduce the overall density of the cable. It is important to choose a conductor spacing that balances these factors based on your specific application.

Insulation Material

The insulation material used in the FFC can also impact its performance and reliability. Different insulation materials have different properties, such as flexibility, durability, and temperature resistance. It is important to choose an insulation material that is appropriate for your application, and to consider factors such as the operating temperature range and the potential for exposure to chemicals or other harsh environments.

Shielding

In some applications, it may be necessary to shield the FFC in order to reduce electromagnetic interference (EMI) or radio frequency interference (RFI). Shielding can be achieved through the use of conductive materials such as foil or braid, which are wrapped around the cable to create a barrier against interference. It is important to consider the potential for interference in your application, and to choose a shielding method that is appropriate for your specific needs.

Applications of Flexible Flat Cable

Flexible flat cable is used in a wide range of applications across various industries. Some of the most common applications include:

| Industry | Application |

|---|---|

| Consumer Electronics | Smartphones, tablets, laptops, wearables |

| Automotive | Infotainment systems, sensors, cameras |

| Medical Devices | Diagnostic equipment, monitoring devices, surgical tools |

| Industrial Automation | Robotics, machine vision, sensors |

| Aerospace | Avionics, in-flight entertainment systems, sensors |

In each of these applications, the benefits of FFC, such as its flexibility, space savings, and high density, make it an ideal choice for connecting components and transmitting signals.

Frequently Asked Questions

- What is the difference between FFC and FPC?

-

FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) are similar in that they are both designed to be thin, lightweight, and flexible. However, FPC typically includes printed circuit traces on a flexible substrate, while FFC consists of flat conductors insulated with a flexible material. FPC may also include additional components such as resistors or capacitors, while FFC is typically used solely for connecting components.

-

Can FFC be used in high-temperature applications?

-

The suitability of FFC for high-temperature applications depends on the specific insulation material used. Some insulation materials, such as polyimide, are designed to withstand high temperatures up to 200°C or more. However, it is important to check the specifications of the specific FFC you are using to ensure that it is rated for your application’s temperature range.

-

How do I choose the right FFC for my application?

- When choosing an FFC for your application, there are several factors to consider, including:

- The number and spacing of conductors required

- The length and thickness of the cable

- The flexibility and durability requirements

- The operating temperature range

- The potential for exposure to chemicals or other harsh environments

-

It is important to work with a reputable FFC manufacturer or supplier to ensure that you are selecting the right cable for your specific needs.

-

Can FFC be customized for specific applications?

-

Yes, FFC can be customized in a variety of ways to meet the specific requirements of different applications. This may include customizing the number and spacing of conductors, the length and thickness of the cable, and the insulation material used. Many FFC manufacturers offer custom design services to help ensure that you get the right cable for your needs.

-

How do I terminate FFC?

- There are several methods for terminating FFC, including:

- Soldering: The conductors can be soldered directly to a PCB or other component.

- Connectors: Specialized connectors can be used to provide a removable connection between the FFC and other components.

- ZIF (Zero Insertion Force) Connectors: These connectors allow the FFC to be inserted and removed without requiring any force, reducing the risk of damage to the cable or components.

- The choice of termination method will depend on factors such as the application requirements, the available space, and the level of reliability required.

Conclusion

Flexible flat cable is a versatile and innovative solution for connecting components in a wide range of electronic devices. Its thin, lightweight, and flexible design offers numerous benefits, including space savings, high density, and cost-effectiveness. When designing with FFC, it is important to consider factors such as cable length, thickness, conductor spacing, insulation material, and shielding to ensure optimal performance and reliability. With its wide range of applications across various industries, FFC is a valuable tool for designers looking to create more innovative and efficient products.

Leave a Reply