Introduction to MEG Circuits

A Motionless Electromagnetic Generator (MEG) is a type of electrical generator that utilizes permanent magnets and electromagnetic coils to generate electricity without any moving parts. The concept behind MEG circuits is based on the principles of electromagnetic induction and the interaction between magnetic fields. In this comprehensive guide, we will explore the design process of a MEG circuit, including the necessary components, calculations, and considerations for optimizing its performance.

Understanding the Basics of Electromagnetic Induction

Before diving into the specifics of MEG circuit design, it is essential to understand the fundamental principles of electromagnetic induction. Electromagnetic induction is the phenomenon where an electric current is generated in a conductor when it is exposed to a changing magnetic field. This principle forms the basis of many electrical generators and transformers.

Faraday’s Law of Induction

Faraday’s Law of Induction states that the electromotive force (EMF) induced in a conductor is proportional to the rate of change of the magnetic flux through the conductor. Mathematically, it can be expressed as:

EMF = -N * (dΦ/dt)

Where:

– EMF is the induced electromotive force (in volts)

– N is the number of turns in the conductor coil

– Φ is the magnetic flux (in webers)

– t is time (in seconds)

This equation highlights the importance of the rate of change of the magnetic flux in generating an induced EMF. In a MEG circuit, the magnetic flux is manipulated through the interaction of permanent magnets and electromagnetic coils to generate a continuous flow of electricity.

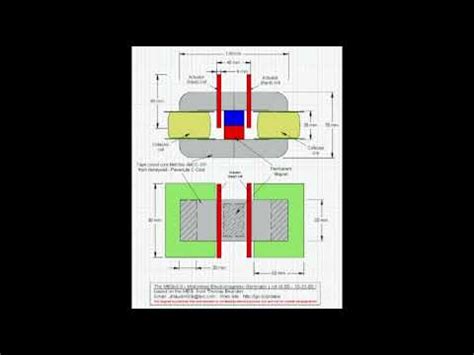

Components of a MEG Circuit

To design a functional MEG circuit, several key components are required. Let’s explore each component in detail:

Permanent Magnets

Permanent magnets are essential for creating the static magnetic field in a MEG circuit. The strength and orientation of the magnets play a crucial role in the overall performance of the generator. Neodymium-Iron-Boron (NdFeB) magnets are commonly used due to their high magnetic field strength and energy density.

When selecting permanent magnets for your MEG circuit, consider the following factors:

– Magnet grade (e.g., N52, N42)

– Dimensions (length, width, thickness)

– Magnetization direction (axial or diametrical)

Electromagnetic Coils

Electromagnetic coils are responsible for interacting with the magnetic field generated by the permanent magnets. These coils typically consist of insulated copper wire wound around a core material, such as ferrite or air. The number of turns, wire gauge, and coil geometry are crucial factors in determining the induced EMF and overall efficiency of the MEG circuit.

When designing electromagnetic coils, consider the following aspects:

– Number of turns

– Wire gauge (AWG)

– Coil diameter and length

– Core material (ferrite, air, or other materials)

Core Materials

The core material used in the electromagnetic coils plays a significant role in the performance of the MEG circuit. Ferrite cores are commonly used due to their high magnetic permeability and low eddy current losses. However, air cores or other materials like powdered iron can also be employed depending on the specific design requirements.

Consider the following factors when selecting a core material:

– Magnetic permeability

– Saturation flux density

– Eddy current losses

– Thermal stability

Additional Components

In addition to the permanent magnets and electromagnetic coils, a MEG circuit may require additional components for proper operation and optimization. These components may include:

- Rectifiers: Used to convert alternating current (AC) to direct current (DC)

- Capacitors: Used for filtering and smoothing the output voltage

- Voltage regulators: Used to maintain a stable output voltage

- Load resistors: Used to simulate the electrical load on the MEG circuit

Designing the MEG Circuit

Now that we have covered the basic components of a MEG circuit, let’s dive into the design process. The following steps will guide you through the creation of a functional MEG circuit:

Step 1: Determine the Desired Output Power

The first step in designing a MEG circuit is to determine the desired output power. This will help you select the appropriate components and dimensions for your generator. Consider factors such as the intended application, available space, and budget when deciding on the output power.

Step 2: Select Permanent Magnets

Based on the desired output power and available space, select the permanent magnets for your MEG circuit. Consider the magnet grade, dimensions, and magnetization direction. Ensure that the magnets are strong enough to generate a sufficient magnetic field for inducing an EMF in the electromagnetic coils.

Step 3: Design Electromagnetic Coils

Design the electromagnetic coils based on the selected permanent magnets and desired output power. Determine the number of turns, wire gauge, coil diameter, and length. Use the following formulas to calculate the induced EMF and coil resistance:

Induced EMF = -N * (dΦ/dt)

Coil Resistance = (ρ * l) / A

Where:

– N is the number of turns

– Φ is the magnetic flux (in webers)

– t is time (in seconds)

– ρ is the resistivity of the wire material (in ohm-meters)

– l is the length of the wire (in meters)

– A is the cross-sectional area of the wire (in square meters)

Step 4: Select Core Material

Choose an appropriate core material for the electromagnetic coils based on the desired performance characteristics. Ferrite cores are commonly used due to their high magnetic permeability and low eddy current losses. Consider factors such as saturation flux density, thermal stability, and cost when selecting the core material.

Step 5: Assemble the MEG Circuit

Once you have designed and fabricated the permanent magnets, electromagnetic coils, and core materials, assemble the MEG circuit according to your design specifications. Ensure proper alignment and spacing between the components to optimize the magnetic flux interaction.

Step 6: Test and Optimize

After assembling the MEG circuit, perform tests to evaluate its performance. Measure the output voltage, current, and power under various load conditions. Optimize the circuit by fine-tuning the component dimensions, materials, and configurations to achieve the desired output characteristics.

Considerations for MEG Circuit Design

When designing a MEG circuit, there are several important considerations to keep in mind:

Magnetic Field Strength and Distribution

The strength and distribution of the magnetic field generated by the permanent magnets are crucial factors in the performance of the MEG circuit. Ensure that the magnets are properly oriented and spaced to maximize the interaction with the electromagnetic coils. Use finite element analysis (FEA) software to simulate the magnetic field distribution and optimize the magnet placement.

Coil Winding Techniques

The technique used for winding the electromagnetic coils can impact the efficiency and performance of the MEG circuit. Consider factors such as winding pattern, wire tension, and insulation when fabricating the coils. Proper winding techniques can minimize electrical losses and improve the overall efficiency of the generator.

Resonance and Frequency Matching

Resonance and frequency matching play a significant role in the performance of a MEG circuit. By matching the resonant frequency of the electromagnetic coils with the frequency of the magnetic flux changes, you can maximize the induced EMF and optimize the power output. Use tuning capacitors or adjust the coil inductance to achieve resonance at the desired frequency.

Thermal Management

MEG circuits can generate heat due to electrical losses in the coils and other components. Proper thermal management is essential to ensure stable operation and prevent overheating. Consider using heat sinks, cooling fans, or other thermal management techniques to dissipate excess heat and maintain optimal operating temperatures.

Shielding and Interference

Electromagnetic interference (EMI) can affect the performance of a MEG circuit. Proper shielding and grounding techniques can help minimize the impact of external electromagnetic fields and ensure stable operation. Use shielded cables, ground planes, and EMI filters to reduce interference and improve signal integrity.

Frequently Asked Questions (FAQ)

1. What is the difference between a MEG circuit and a traditional electromagnetic generator?

A MEG circuit generates electricity without any moving parts, relying on the interaction between permanent magnets and electromagnetic coils. In contrast, traditional electromagnetic generators use rotating or moving components to generate electricity through electromagnetic induction.

2. Can a MEG circuit generate free energy?

No, a MEG circuit cannot generate free energy. The principles of energy conservation dictate that energy cannot be created or destroyed, only converted from one form to another. A MEG circuit converts the energy stored in the permanent magnets into electrical energy, but it does not create energy out of nothing.

3. What are the advantages of using a MEG circuit over other types of generators?

MEG circuits offer several advantages over other types of generators:

– No moving parts, leading to reduced wear and maintenance

– Silent operation due to the absence of mechanical noise

– Potential for compact and lightweight designs

– Ability to generate electricity at various scales, from small portable devices to larger power systems

4. How efficient are MEG circuits compared to traditional generators?

The efficiency of MEG circuits can vary depending on the specific design and components used. While some MEG circuits have demonstrated efficiencies comparable to or higher than traditional generators, others may have lower efficiencies. Continuous research and development efforts aim to improve the efficiency and practicality of MEG circuits.

5. Are MEG circuits commercially available?

Currently, MEG circuits are primarily in the research and development stage. While there have been various claims and demonstrations of functional MEG devices, they are not widely commercially available. Further advancements in materials science, manufacturing techniques, and overall system optimization are required to make MEG circuits a viable commercial technology.

Conclusion

Designing a Motionless Electromagnetic Generator (MEG) circuit requires a deep understanding of electromagnetic principles, careful component selection, and thorough testing and optimization. By following the steps outlined in this guide and considering the various design factors, you can create a functional MEG circuit that generates electricity without any moving parts.

However, it is important to approach MEG technology with a scientific mindset and realistic expectations. While MEG circuits hold promise for innovative power generation solutions, they are still in the early stages of development and require further research and refinement to achieve practical and efficient performance.

As you embark on your journey to design a MEG circuit, remember to experiment, learn from failures, and collaborate with others in the field. With dedication and perseverance, you can contribute to the advancement of this exciting technology and help shape the future of sustainable energy generation.

Leave a Reply