What are PCB Pins?

PCB pins, also known as printed circuit board pins or header pins, are small metal components that are used to create electrical connections between different parts of a printed circuit board (PCB). They are essential components in modern electronics, allowing for the easy and reliable connection of various components such as microcontrollers, sensors, and other modules to the main PCB.

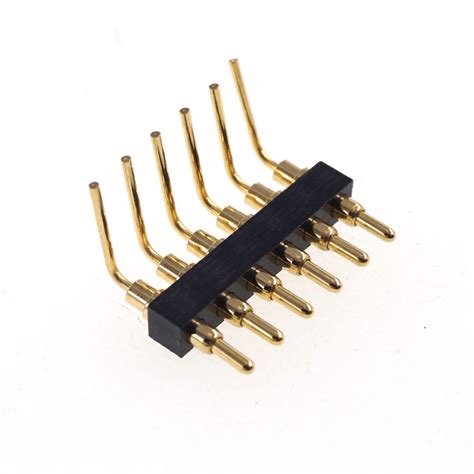

PCB pins come in various shapes, sizes, and materials, depending on the specific application and requirements. They are typically made of copper or brass and are plated with gold, silver, or tin to improve conductivity and prevent corrosion.

Types of PCB Pins

There are several types of PCB pins available, each with its own unique characteristics and uses. Some of the most common types include:

-

Through-hole pins: These pins are designed to be inserted into holes drilled in the PCB and soldered in place. They provide a strong mechanical connection and are often used for components that require high reliability or are subject to mechanical stress.

-

Surface-mount pins: These pins are designed to be soldered directly onto the surface of the PCB, without the need for holes. They are smaller and more compact than through-hole pins, making them ideal for high-density PCB designs.

-

Press-fit pins: These pins are designed to be pressed into plated through-holes in the PCB, creating a secure mechanical and electrical connection without the need for soldering. They are often used in applications where soldering is not possible or desirable, such as in automotive or aerospace electronics.

-

Wire-wrap pins: These pins are designed to be used with wire-wrapping techniques, where a thin wire is tightly wrapped around the pin to create a secure electrical connection. They are often used in prototyping or low-volume production, as they allow for easy modification and testing of circuits.

| Pin Type | Characteristics | Applications |

|---|---|---|

| Through-hole pins | Strong mechanical connection, high reliability | Components subject to mechanical stress |

| Surface-mount pins | Compact, high-density designs | High-density PCB layouts |

| Press-fit pins | No soldering required, secure connection | Automotive, aerospace electronics |

| Wire-wrap pins | Easy modification and testing | Prototyping, low-volume production |

How to Use PCB Pins

Using PCB pins is a straightforward process, but it requires some basic knowledge of electronic assembly techniques. Here are the general steps involved in using PCB pins:

1. Choosing the Right Pins

The first step in using PCB pins is to choose the right type and size of pins for your specific application. Consider factors such as the type of components you will be connecting, the available space on your PCB, and the environmental conditions your device will be exposed to.

2. Preparing the PCB

Before installing the pins, you need to prepare your PCB. This involves designing the PCB layout, specifying the locations and sizes of the pin holes or pads, and manufacturing the PCB according to your design.

3. Installing the Pins

Once your PCB is ready, you can install the pins. The specific installation method will depend on the type of pins you are using:

- For through-hole pins, insert the pins into the designated holes in the PCB and solder them in place using a soldering iron and solder.

- For surface-mount pins, place the pins onto the designated pads on the PCB and solder them in place using a reflow oven or a soldering iron.

- For press-fit pins, align the pins with the plated through-holes and press them into place using a press-fit installation tool.

- For wire-wrap pins, insert the pins into the designated holes and secure them in place using a wire-wrapping tool.

4. Connecting Components

After installing the pins, you can connect your components to the PCB using the appropriate methods, such as soldering, crimping, or wire-wrapping. Ensure that all connections are secure and properly insulated to prevent short circuits or other issues.

5. Testing and Troubleshooting

Once your PCB is fully assembled, it’s essential to test it thoroughly to ensure that all connections are working correctly and that there are no short circuits or other issues. Use a multimeter or other testing equipment to verify the continuity and resistance of each connection, and make any necessary repairs or adjustments.

Advantages of Using PCB Pins

Using PCB pins offers several advantages over other connection methods, such as soldering components directly to the PCB or using connectors. Some of the key benefits include:

-

Versatility: PCB pins can be used with a wide range of components and modules, making them suitable for a variety of applications and projects.

-

Ease of use: Installing and connecting components using PCB pins is generally easier and faster than soldering components directly to the PCB, especially for beginners or those working on complex projects.

-

Modularity: PCB pins allow for the easy replacement or upgrading of individual components without the need to desolder and resolder the entire PCB.

-

Reliability: When installed correctly, PCB pins provide a secure and reliable electrical connection that can withstand vibration, shock, and other environmental stresses.

-

Prototyping: PCB pins are particularly useful for prototyping and testing, as they allow for quick and easy modifications to the circuit without the need for extensive rework.

Disadvantages of Using PCB Pins

While PCB pins offer many benefits, there are also some potential drawbacks to consider:

-

Cost: PCB pins can be more expensive than other connection methods, particularly for high-volume production runs.

-

Space: PCB pins require additional space on the PCB compared to direct soldering, which can be a concern for very compact or high-density designs.

-

Mechanical strength: In some cases, the mechanical strength of PCB pins may be lower than that of directly soldered connections, particularly for heavy or large components.

-

Compatibility: Some components or modules may not be compatible with certain types of PCB pins, requiring the use of adapters or alternative connection methods.

Frequently Asked Questions (FAQ)

-

Q: Can I mix different types of PCB pins on the same board?

A: Yes, you can mix different types of PCB pins on the same board, as long as they are compatible with the components and the PCB design. However, it’s essential to ensure that the pins are properly spaced and aligned to avoid interference or short circuits. -

Q: How do I choose the right size of PCB pins for my project?

A: The size of PCB pins you choose will depend on the specific requirements of your project, such as the size and spacing of the components, the available space on the PCB, and the current and voltage ratings of the circuit. Consult the datasheets of your components and the specifications of the PCB pins to ensure compatibility. -

Q: Can I reuse PCB pins?

A: In most cases, PCB pins can be reused if they are in good condition and have not been damaged during the removal process. However, it’s essential to inspect the pins carefully for any signs of wear, corrosion, or deformation before reusing them, as this can affect their performance and reliability. -

Q: How do I prevent short circuits when using PCB pins?

A: To prevent short circuits when using PCB pins, ensure that the pins are properly spaced and aligned, and that there are no loose or stray wires or debris on the PCB. Use insulating materials such as heat shrink tubing or electrical tape to cover exposed connections, and always double-check your work before applying power to the circuit. -

Q: Can I use PCB pins for high-frequency or RF applications?

A: While PCB pins can be used for high-frequency or RF applications, they may not always be the best choice due to their potential to introduce unwanted inductance or capacitance into the circuit. For these applications, specialized connectors or direct soldering may be more appropriate. Always consider the specific requirements and constraints of your project when choosing a connection method.

Conclusion

PCB pins are essential components in modern electronics, providing a versatile, reliable, and easy-to-use method for connecting components and modules to printed circuit boards. By understanding the different types of PCB pins available, their advantages and disadvantages, and the proper techniques for installing and using them, you can create robust and efficient electronic devices that meet your specific needs and requirements.

As with any electronic assembly process, using PCB pins requires careful planning, attention to detail, and proper tools and techniques. By following best practices and continuously learning and improving your skills, you can unlock the full potential of PCB pins and take your electronics projects to the next level.

Leave a Reply