Introduction to 94v0 Circuit Boards

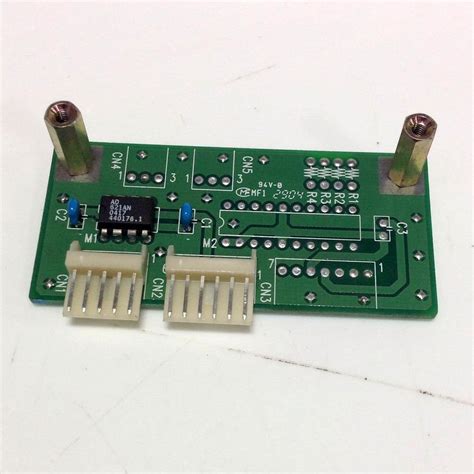

A 94v0 circuit board, also known as a printed circuit board (PCB), is an essential component in electronic devices. It serves as the foundation for connecting and supporting various electronic components. The “94v0” designation indicates that the board is made from a flame-retardant material that meets the UL94V-0 flammability standard.

What is a 94v0 Circuit Board?

A 94v0 circuit board is a type of PCB that is constructed using a flame-retardant substrate material. This material is designed to resist ignition and prevent the spread of flames in case of a fire. The “94” in the name refers to the UL94 flammability standard, while the “v0” indicates that the material has passed the highest level of the vertical burning test.

Advantages of Using 94v0 Circuit Boards

There are several advantages to using 94v0 circuit boards in electronic devices:

- Enhanced safety: The flame-retardant properties of 94v0 boards help prevent fires and ensure the safety of users and surrounding equipment.

- Durability: 94v0 boards are more durable and resistant to heat compared to non-flame-retardant boards.

- Compliance with industry standards: Using 94v0 boards ensures compliance with various industry standards and regulations related to fire safety.

- Versatility: 94v0 boards can be used in a wide range of applications, from consumer electronics to industrial equipment.

Key Features of 94v0 Circuit Boards

Flame Retardancy

The most critical feature of a 94v0 circuit board is its flame-retardant properties. The board is made from a substrate material that has been treated with flame-retardant chemicals. These chemicals help to prevent the board from igniting and spreading flames in case of a fire.

UL94V-0 Flammability Standard

The UL94V-0 flammability standard is a widely recognized safety standard for electronic components and materials. It is a vertical burning test that measures the ability of a material to self-extinguish and prevent the spread of flames. To meet the UL94V-0 standard, a material must:

- Not burn for more than 10 seconds after the ignition source is removed

- Not produce flaming drips that ignite a cotton indicator placed below the sample

- Have a total flaming time of less than 50 seconds for 10 flame applications

Copper Layers and Traces

94v0 circuit boards typically consist of multiple layers of copper traces separated by insulating layers. The number of copper layers can vary depending on the complexity of the circuit design. The copper traces are responsible for carrying electrical signals between components on the board.

Types of Copper Layers

There are two main types of copper layers used in 94v0 circuit boards:

- Signal layers: These layers are used for carrying electrical signals between components on the board. They are typically thinner than power and ground layers.

- Power and ground layers: These layers are used for distributing power and providing a reference ground for the circuit. They are typically thicker than signal layers to handle higher currents.

| Layer Type | Thickness | Purpose |

|---|---|---|

| Signal | 0.5-1 oz | Carrying electrical signals |

| Power/Ground | 1-2 oz | Distributing power and providing reference ground |

Solder Mask and Silkscreen

In addition to the copper layers, 94v0 circuit boards also feature a solder mask and silkscreen. The solder mask is a protective layer that covers the copper traces, leaving only the pads exposed for soldering components. The silkscreen is a printed layer that provides text and symbols for identifying components and their locations on the board.

Solder Mask Colors

Solder masks are available in various colors, with green being the most common. Other popular colors include:

- Blue

- Red

- Yellow

- Black

- White

The choice of solder mask color is often a matter of personal preference or branding requirements.

Silkscreen Colors

Silkscreen is typically printed in white color on top of the solder mask. However, other colors such as black or yellow can also be used for better contrast against certain solder mask colors.

Applications of 94v0 Circuit Boards

94v0 circuit boards are used in a wide range of electronic devices and applications. Some common examples include:

Consumer Electronics

- Smartphones and tablets

- Laptops and desktop computers

- Televisions and home entertainment systems

- Gaming consoles and controllers

Industrial Equipment

- Process control systems

- Automation and robotics

- Test and measurement equipment

- Power supplies and converters

Medical Devices

- Patient monitoring systems

- Diagnostic equipment

- Surgical instruments

- Wearable medical devices

Automotive Electronics

- Engine control units (ECUs)

- Infotainment systems

- Advanced driver assistance systems (ADAS)

- Electric vehicle charging systems

94v0 Circuit Board Design Considerations

When designing a 94v0 circuit board, there are several key factors to consider:

Component Placement

Proper component placement is crucial for ensuring the optimal performance and reliability of the circuit. Components should be placed in a way that minimizes the length of copper traces and reduces the risk of signal interference.

Trace Width and Spacing

The width and spacing of copper traces on a 94v0 circuit board should be carefully calculated based on the current carrying requirements and signal integrity considerations. Traces that are too narrow or too close together can lead to signal integrity issues and potential failures.

| Trace Current | Minimum Trace Width (mm) |

|---|---|

| 0.5A | 0.2 |

| 1A | 0.3 |

| 2A | 0.4 |

| 3A | 0.6 |

Via Placement and Sizing

Vias are used to connect copper traces on different layers of the circuit board. The placement and sizing of vias should be optimized to minimize signal reflections and ensure reliable connections between layers.

Thermal Management

Proper thermal management is essential for preventing overheating and ensuring the long-term reliability of the circuit board. This can be achieved through the use of thermal vias, heatsinks, and other cooling techniques.

FAQ

What does “94v0” mean in the context of circuit boards?

“94v0” refers to the UL94V-0 flammability standard, which is a safety standard for electronic components and materials. Circuit boards that meet this standard are made from flame-retardant materials that resist ignition and prevent the spread of flames.

Are 94v0 circuit boards more expensive than non-flame-retardant boards?

Yes, 94v0 circuit boards are typically more expensive than non-flame-retardant boards due to the additional processing and materials required to achieve the flame-retardant properties.

Can 94v0 circuit boards be used in all electronic devices?

While 94v0 circuit boards can be used in a wide range of electronic devices, they may not be necessary or cost-effective for all applications. The decision to use a 94v0 board should be based on the specific safety and performance requirements of the device.

How do I choose the right solder mask color for my 94v0 circuit board?

The choice of solder mask color is often a matter of personal preference or branding requirements. Green is the most common color, but other colors such as blue, red, yellow, black, and white are also available.

What are some key design considerations for 94v0 circuit boards?

When designing a 94v0 circuit board, some key factors to consider include component placement, trace width and spacing, via placement and sizing, and thermal management. Proper attention to these factors can help ensure the optimal performance and reliability of the circuit board.

Conclusion

94v0 circuit boards are essential components in a wide range of electronic devices, offering enhanced safety and reliability through their flame-retardant properties. By understanding the key features and applications of these boards, as well as the important design considerations, engineers and manufacturers can create high-quality electronic products that meet the needs of their customers and comply with industry safety standards.

Leave a Reply