What is a Low Voltage Cutoff Circuit?

A low voltage cutoff circuit is an electronic circuit that monitors the voltage of a battery and disconnects the load when the voltage drops below a predetermined threshold. This prevents the battery from being over-discharged, which can lead to reduced performance, shorter lifespan, and even permanent damage.

Why is a Low Voltage Cutoff Circuit Important?

Batteries have a minimum voltage level below which they should not be discharged. If a battery is discharged beyond this point, it may suffer from the following issues:

- Reduced capacity: Over-discharging a battery can cause irreversible chemical changes, leading to a permanent reduction in its capacity.

- Shorter lifespan: Repeatedly over-discharging a battery will significantly shorten its lifespan.

- Safety hazards: Some batteries, such as lithium-ion batteries, can become unstable and pose a safety risk if over-discharged.

By using a low voltage cutoff circuit, you can ensure that your battery-powered devices operate within safe limits and prolong the life of the battery.

How Does a Low Voltage Cutoff Circuit Work?

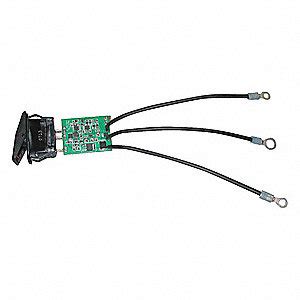

A low voltage cutoff circuit consists of three main components:

- Voltage sensor: This component monitors the battery voltage and provides a signal when the voltage drops below a predetermined threshold.

- Comparator: The comparator takes the signal from the voltage sensor and compares it with a reference voltage. When the battery voltage drops below the reference voltage, the comparator triggers the switch.

- Switch: The switch is responsible for disconnecting the load from the battery when triggered by the comparator. This can be an electronic switch, such as a transistor or a relay.

Here’s a simple block diagram illustrating the working principle of a low voltage cutoff circuit:

+---------+ +------------+ +--------+

| Voltage |---->| Comparator |---->| Switch |

| Sensor | +------------+ +--------+

+---------+ | |

| |

+----+----+ |

|Reference| |

| Voltage | |

+---------+ |

|

+------+-------+

| Load |

+-------------+

When the battery voltage drops below the reference voltage, the comparator sends a signal to the switch, which then disconnects the load from the battery.

Designing a Low Voltage Cutoff Circuit

To design a low voltage cutoff circuit, you need to consider the following factors:

-

Battery type and voltage: Different batteries have different minimum discharge voltages. For example, a lithium-ion battery should not be discharged below 3.0V per cell, while a lead-acid battery should not be discharged below 1.75V per cell. Choose a reference voltage based on the battery type and the number of cells in series.

-

Load current: The low voltage cutoff circuit should be able to handle the maximum load current. Choose components that can handle the expected current levels.

-

Hysteresis: To prevent the circuit from oscillating between on and off states when the battery voltage is close to the threshold, add a small amount of hysteresis. This can be achieved by using a comparator with built-in hysteresis or by adding a feedback resistor.

Schematic Diagram

Here’s a schematic diagram of a simple low voltage cutoff circuit using a comparator and a MOSFET:

+-------+

|Battery|

+---+---+

|

|

+----+----+

| Voltage |

| Divider |

+-+-----+-+

| |

| |

+---+-----+---+

|Comparator |

+---+---+ +---+---+

| - | | + |

| | | |

+---+---+ +---+---+

| |

| |

| +--------+

+----+MOSFET |

| |

| +--+--+

+-----|Load |

+-----+

In this circuit, the voltage divider is used to scale down the battery voltage to a level suitable for the comparator. The comparator compares the scaled voltage with a reference voltage and triggers the MOSFET when the battery voltage drops below the threshold. The MOSFET acts as a switch, disconnecting the load from the battery.

Component Selection

To build the low voltage cutoff circuit, you will need the following components:

-

Comparator: Choose a comparator with low power consumption and a suitable voltage range. For example, the LM393 is a popular choice for 5V systems.

-

MOSFET: Select a MOSFET with a low on-resistance and a sufficient current rating for your load. The IRF540 is a common choice for low-voltage, high-current applications.

-

Voltage divider resistors: Choose resistors with values that scale the battery voltage to a level suitable for the comparator. A typical voltage divider ratio is 1:1, which halves the battery voltage.

-

Reference voltage: Use a stable reference voltage source, such as a zener diode or a voltage reference IC, to set the threshold voltage for the comparator.

Constructing the Low Voltage Cutoff Circuit

Follow these steps to build the low voltage cutoff circuit:

- Assemble the voltage divider:

- Connect two resistors in series between the battery positive terminal and ground.

-

The junction point of the two resistors will provide the scaled voltage for the comparator.

-

Connect the comparator:

- Connect the scaled voltage from the voltage divider to the non-inverting input (+) of the comparator.

- Connect the reference voltage to the inverting input (-) of the comparator.

-

Connect the comparator’s power supply pins to the battery positive terminal and ground.

-

Connect the MOSFET:

- Connect the gate of the MOSFET to the output of the comparator.

- Connect the drain of the MOSFET to the load positive terminal.

-

Connect the source of the MOSFET to the battery negative terminal.

-

Test the circuit:

- Connect the load to the circuit.

- Gradually reduce the battery voltage using a Variable Power Supply or by discharging the battery.

- Observe the voltage at which the load is disconnected.

- Adjust the reference voltage or voltage divider ratio if needed to achieve the desired cutoff voltage.

Example Low Voltage Cutoff Circuit for a 12V Lead-Acid Battery

Let’s design a low voltage cutoff circuit for a 12V lead-acid battery. Lead-acid batteries should not be discharged below 10.5V to prevent damage.

Component Selection

- Comparator: LM393

- MOSFET: IRF540

- Voltage divider resistors: 10kΩ and 10kΩ

- Reference voltage: 5.25V (using a 5.25V zener diode)

Schematic Diagram

+-------+

| 12V |

|Battery|

+---+---+

|

|

+----+----+

| 10kΩ |

+--+---+--+

| |

| |

| +--+

| |

| 10kΩ|

| |

+------+

|

|

+---+---+

|LM393 |

+---+---+---+---+

+---| - | + |---+

| | | | |

| +-------+-------+ |

| |

| +---+---+

| +-----|IRF540 |----+

| | +-------+ |

| | |

+-------------+ |

|

+----+----+

| Load |

+---------+

In this circuit, the voltage divider scales the 12V battery voltage down to 6V at the non-inverting input of the comparator. The 5.25V zener diode provides a stable reference voltage at the inverting input. When the battery voltage drops below 10.5V, the scaled voltage at the non-inverting input will be less than 5.25V, causing the comparator output to go low and turning off the MOSFET, disconnecting the load from the battery.

Frequently Asked Questions (FAQ)

-

What is the purpose of a low voltage cutoff circuit?

A low voltage cutoff circuit protects batteries from over-discharge by disconnecting the load when the battery voltage drops below a predetermined threshold. -

Why is it important to prevent battery over-discharge?

Over-discharging a battery can cause irreversible chemical changes, leading to reduced capacity, shorter lifespan, and potential safety hazards. -

What are the main components of a low voltage cutoff circuit?

The main components of a low voltage cutoff circuit are a voltage sensor, a comparator, and a switch (usually a MOSFET). -

How do I choose the appropriate reference voltage for my low voltage cutoff circuit?

The reference voltage should be chosen based on the minimum discharge voltage of the battery type you are using. For example, a lithium-ion battery should not be discharged below 3.0V per cell, so the reference voltage should be set accordingly. -

Can a low voltage cutoff circuit be used with any type of battery?

Yes, a low voltage cutoff circuit can be designed for any type of battery by selecting the appropriate reference voltage and components based on the Battery Specifications and load requirements.

Conclusion

A low voltage cutoff circuit is a crucial component in battery-powered electronic devices, ensuring that batteries are not over-discharged, which can lead to reduced performance, shorter lifespan, and safety hazards. By understanding the working principle of a low voltage cutoff circuit and following the steps to design and construct one, you can protect your batteries and extend the life of your electronic devices.

Leave a Reply