Introduction to Gerber Files

Gerber files are a standard file format used in the printed circuit board (PCB) industry to describe the layout of a PCB. They are named after the Gerber Scientific Instrument Company, which developed the format in the 1960s. Gerber files are used to transfer PCB design information from computer-aided design (CAD) software to manufacturing equipment, such as plotters, photo plotters, and CNC machines.

Types of Gerber Files

There are two main types of Gerber files:

- Gerber RS-274D: This is the older format, which has been used since the 1980s. It is also known as Extended Gerber or Gerber X1.

- Gerber RS-274X: This is the newer format, introduced in 1998. It is also known as Gerber X2.

Differences between Gerber and Gerber X2 Files

File Extension

- Gerber RS-274D files use the file extension

.gbr. - Gerber X2 files use the file extension

.gb2or.gbx.

Aperture Definitions

- In Gerber RS-274D, aperture definitions are separate from the main file and are typically stored in an aperture list file with the extension

.apror.lst. - In Gerber X2, aperture definitions are embedded within the main file, making the file self-contained and eliminating the need for a separate aperture list file.

Attribute Data

- Gerber RS-274D does not support attribute data.

- Gerber X2 introduces attribute data, which allows for the inclusion of additional information about the PCB, such as layer types, pad functions, and netlist data. This information is enclosed in

%characters and appears as comments in the file.

Coordinate Format

- Gerber RS-274D uses a fixed-point coordinate format, with coordinates represented as integers.

- Gerber X2 introduces a floating-point coordinate format, which allows for greater precision and eliminates the need for leading zeros.

Macro Apertures

- In Gerber RS-274D, macro apertures are defined using the

AM(Aperture Macro) command, followed by the macro definition. - In Gerber X2, macro apertures are defined using the

%AMcommand, which is more consistent with the attribute data syntax.

Polarity and Rotation

- Gerber RS-274D does not have explicit commands for setting the polarity (dark or clear) or rotation of apertures.

- Gerber X2 introduces the

%LPD*%and%LPC*%commands for setting the polarity to dark or clear, respectively, and the%IRcommand for setting the aperture rotation.

Advantages of Gerber X2

- Self-contained files: With embedded aperture definitions and attribute data, Gerber X2 files are self-contained, reducing the risk of errors caused by mismatched or missing aperture list files.

- Improved precision: The floating-point coordinate format in Gerber X2 allows for greater precision in PCB layouts.

- Enhanced information: Attribute data in Gerber X2 files provides additional information about the PCB, making it easier for manufacturers to understand the designer’s intent and catch potential issues early in the production process.

- Standardization: Gerber X2 offers a more standardized and consistent way of representing PCB data, reducing the potential for misinterpretation and errors.

Comparing Gerber and Gerber X2

| Feature | Gerber RS-274D | Gerber X2 |

|---|---|---|

| File Extension | .gbr |

.gb2 or .gbx |

| Aperture Definitions | Separate file (.apr or .lst) |

Embedded in main file |

| Attribute Data | Not supported | Supported |

| Coordinate Format | Fixed-point (integers) | Floating-point |

| Macro Apertures | Defined using AM command |

Defined using %AM command |

| Polarity and Rotation | No explicit commands | %LPD*%, %LPC*%, and %IR commands |

Frequently Asked Questions (FAQ)

-

Q: Can Gerber X2 files be used with older PCB manufacturing equipment?

A: Most modern PCB manufacturing equipment supports both Gerber RS-274D and Gerber X2 file formats. However, some older equipment may only support Gerber RS-274D. In such cases, it is possible to convert Gerber X2 files to Gerber RS-274D using CAD software or file conversion tools. -

Q: Are Gerber X2 files backward compatible with Gerber RS-274D?

A: No, Gerber X2 files are not backward compatible with Gerber RS-274D due to the differences in file structure and commands. However, Gerber RS-274D files can be used with systems that support Gerber X2. -

Q: Do all PCB manufacturers support Gerber X2 files?

A: Most PCB manufacturers today support Gerber X2 files, as it has become the preferred format in the industry. However, it is always a good idea to check with your specific manufacturer to ensure they can work with Gerber X2 files. -

Q: What are the benefits of using Gerber X2 files over Gerber RS-274D?

A: Gerber X2 files offer several advantages, including self-contained files with embedded aperture definitions and attribute data, improved precision with floating-point coordinates, and enhanced standardization. These features can help reduce errors and improve the overall PCB manufacturing process. -

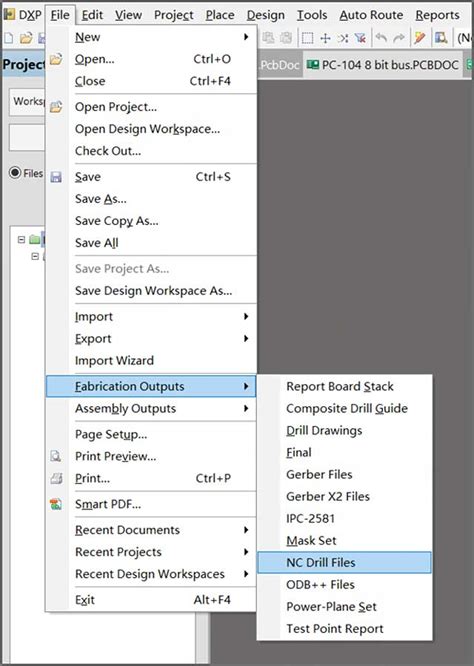

Q: Can I use Gerber X2 files with my existing CAD software?

A: Most modern PCB CAD software supports exporting designs in both Gerber RS-274D and Gerber X2 formats. Check your software’s documentation or support resources to learn how to export Gerber X2 files. If your current software does not support Gerber X2, you may need to upgrade to a newer version or consider alternative CAD solutions.

Conclusion

Gerber X2 represents a significant improvement over the older Gerber RS-274D format, offering a more standardized, precise, and information-rich way of representing PCB data. With self-contained files, floating-point coordinates, and attribute data, Gerber X2 helps streamline the PCB manufacturing process and reduce the potential for errors.

While Gerber RS-274D is still widely used and supported, the industry is gradually shifting towards the adoption of Gerber X2. As a PCB designer, it is essential to understand the differences between these two formats and communicate with your manufacturer to ensure your design files are compatible with their systems and processes.

By embracing Gerber X2 and taking advantage of its enhanced features, you can create more accurate and informative PCB design files, ultimately leading to better collaboration with manufacturers and a more efficient production process.

Leave a Reply