What is Electroless Gold-Nickel Plating?

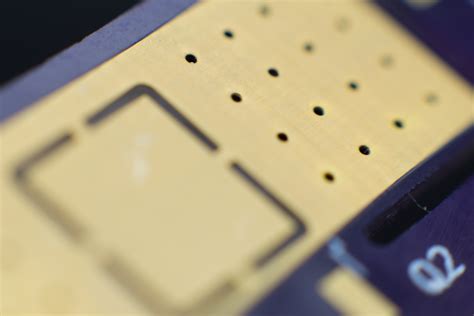

Electroless gold-nickel (Au/Ni) plating is a multi-layer metal finishing process that deposits a thin layer of gold over a nickel underlayer on a substrate material, without the use of an external electrical current. The nickel layer provides excellent corrosion resistance and acts as a diffusion barrier, while the gold layer offers superior electrical conductivity, wear resistance, and protection against oxidation.

This chemical plating process involves the autocatalytic reduction of metal ions in an aqueous solution, resulting in a uniform coating on the substrate surface. Electroless Au/Ni plating is widely used in the electronics industry for printed circuit boards (PCBs), connectors, and other components that require reliable and durable surface finishes.

Advantages of Electroless Gold-Nickel Plating

- Excellent corrosion resistance

- Superior wear resistance

- High electrical conductivity

- Uniform coating thickness, even on complex geometries

- RoHS and REACH compliant

- Good solderability and wire bonding capabilities

RoHS Compliance and Electroless Gold-Nickel Plating

The Restriction of Hazardous Substances (RoHS) Directive is a European Union regulation that limits the use of certain hazardous substances in electrical and electronic equipment. The directive aims to reduce the environmental impact and health risks associated with the disposal of electronic waste.

Electroless Au/Ni plating is RoHS compliant as it does not contain any of the restricted substances, such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), or polybrominated diphenyl ethers (PBDEs). This makes it an ideal choice for manufacturers who need to comply with the RoHS Directive while ensuring high-quality surface finishes for their products.

RoHS Restricted Substances and Maximum Concentration Values

| Substance | Maximum Concentration Value |

|---|---|

| Lead (Pb) | 0.1% |

| Mercury (Hg) | 0.1% |

| Cadmium (Cd) | 0.01% |

| Hexavalent Chromium (Cr6+) | 0.1% |

| Polybrominated Biphenyls (PBBs) | 0.1% |

| Polybrominated Diphenyl Ethers (PBDEs) | 0.1% |

Electroless Gold-Nickel Plating Process

The electroless Au/Ni plating process involves several steps to ensure a high-quality, uniform coating on the substrate surface. The general process flow is as follows:

-

Cleaning: The substrate is thoroughly cleaned to remove any contaminants, such as oils, greases, or oxides, that may interfere with the plating process.

-

Surface preparation: The substrate surface is etched or activated to improve adhesion of the nickel layer.

-

Electroless nickel plating: The substrate is immersed in an electroless nickel plating solution, where the nickel ions are reduced and deposited onto the surface. The nickel layer thickness is typically between 1-10 μm.

-

Rinsing: The nickel-plated substrate is rinsed with deionized water to remove any residual plating solution.

-

Electroless gold plating: The nickel-plated substrate is then immersed in an electroless gold plating solution, where the gold ions are reduced and deposited onto the nickel surface. The gold layer thickness is usually between 0.05-0.5 μm.

-

Final rinsing and drying: The Au/Ni plated substrate is rinsed with deionized water and dried using hot air or nitrogen gas.

Factors Affecting Electroless Gold-Nickel Plating Quality

Several factors can influence the quality and performance of electroless Au/Ni plating:

- Substrate material and surface preparation

- Plating solution composition and purity

- Operating parameters, such as temperature, pH, and agitation

- Contaminants and impurities in the plating solution

- Post-plating handling and storage conditions

To ensure consistent and high-quality results, it is essential to control these factors and follow best practices throughout the plating process.

Applications of Electroless Gold-Nickel Plating

Electroless Au/Ni plating finds extensive applications in various industries, particularly in the electronics sector. Some common applications include:

-

Printed Circuit Boards (PCBs): Au/Ni plating is used to protect copper traces and pads from corrosion and wear, while providing excellent solderability and electrical conductivity.

-

Connectors: Electroless Au/Ni plating is applied to connector contacts to ensure reliable electrical connections and prevent corrosion.

-

Semiconductor Packaging: Au/Ni plating is used on leadframes and other components in semiconductor packages to enhance wire bonding performance and protect against environmental factors.

-

Aerospace and Defense: Electroless Au/Ni plating is used on various components in aerospace and defense applications due to its excellent corrosion resistance and durability.

-

Medical Devices: Au/Ni plating is used on medical device components to provide biocompatibility, corrosion resistance, and wear resistance.

Case Study: Electroless Gold-Nickel Plating for High-Reliability Connectors

A major connector manufacturer was facing challenges with corrosion and wear on their high-density connectors used in harsh industrial environments. The existing surface finish was not providing adequate protection, leading to premature failures and customer complaints.

The manufacturer decided to switch to electroless Au/Ni plating for their connector contacts. The Au/Ni plating process was optimized to achieve a nickel layer thickness of 5 μm and a gold layer thickness of 0.2 μm. The plated connectors were subjected to various performance tests, including salt spray corrosion, wear resistance, and electrical conductivity.

The results showed significant improvements in corrosion resistance and wear resistance compared to the previous surface finish. The Au/Ni plated connectors also demonstrated excellent electrical conductivity and reliability, even after extended exposure to harsh environments.

By adopting electroless Au/Ni plating, the connector manufacturer was able to enhance the performance and durability of their products, while ensuring compliance with RoHS regulations. This resulted in increased customer satisfaction, reduced warranty claims, and improved market share in the competitive connector industry.

Comparing Electroless Gold-Nickel Plating with Other Surface Finishes

Electroless Au/Ni plating offers several advantages over other common surface finishes used in the electronics industry. Here’s a comparison of Au/Ni plating with some popular alternatives:

Electroless Gold-Nickel vs. Immersion Gold

Immersion gold plating is a single-layer process that deposits a thin layer of gold directly onto the substrate material, typically copper. While immersion gold provides good solderability and wire bonding performance, it lacks the corrosion resistance and durability offered by the nickel underlayer in Au/Ni plating.

| Property | Electroless Gold-Nickel | Immersion Gold |

|---|---|---|

| Corrosion Resistance | Excellent | Good |

| Wear Resistance | Excellent | Fair |

| Solderability | Good | Excellent |

| Wire Bonding Performance | Good | Excellent |

| Coating Thickness | Au: 0.05-0.5 μm, Ni: 1-10 μm | Au: 0.05-0.2 μm |

Electroless Gold-Nickel vs. ENIG (Electroless Nickel Immersion Gold)

ENIG is a two-layer plating process that involves an electroless nickel underlayer and an immersion gold top layer. While ENIG offers good solderability and corrosion resistance, the immersion gold layer is thinner compared to electroless gold, resulting in slightly lower wear resistance and durability.

| Property | Electroless Gold-Nickel | ENIG |

|---|---|---|

| Corrosion Resistance | Excellent | Good |

| Wear Resistance | Excellent | Good |

| Solderability | Good | Excellent |

| Wire Bonding Performance | Good | Good |

| Coating Thickness | Au: 0.05-0.5 μm, Ni: 1-10 μm | Au: 0.05-0.1 μm, Ni: 3-6 μm |

Frequently Asked Questions (FAQ)

-

Q: Is electroless Au/Ni plating RoHS compliant?

A: Yes, electroless Au/Ni plating is RoHS compliant as it does not contain any of the restricted substances listed in the RoHS Directive. -

Q: What are the typical thicknesses of the nickel and gold layers in electroless Au/Ni plating?

A: The nickel layer thickness is typically between 1-10 μm, while the gold layer thickness is usually between 0.05-0.5 μm. -

Q: Can electroless Au/Ni plating be applied to any substrate material?

A: Electroless Au/Ni plating can be applied to various substrate materials, including copper, nickel, and aluminum. However, proper surface preparation is essential to ensure good adhesion and plating quality. -

Q: How does electroless Au/Ni plating compare to ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)?

A: ENEPIG offers similar benefits to electroless Au/Ni plating, with the addition of a thin palladium layer between the nickel and gold layers. The palladium layer enhances wire bonding performance and provides additional oxidation resistance. However, ENEPIG is a more complex and expensive process compared to electroless Au/Ni plating. -

Q: What are the main advantages of using electroless Au/Ni plating for electronic components?

A: The main advantages of electroless Au/Ni plating include excellent corrosion resistance, superior wear resistance, high electrical conductivity, uniform coating thickness, RoHS compliance, and good solderability and wire bonding capabilities. These properties make it an ideal choice for various electronic components exposed to harsh environments or requiring reliable electrical connections.

Conclusion

Electroless gold-nickel (Au/Ni) plating is a versatile and high-performance surface finishing process that offers numerous benefits for the electronics industry. Its excellent corrosion resistance, wear resistance, and electrical conductivity make it an ideal choice for various applications, including printed circuit boards, connectors, and semiconductor packaging.

As an RoHS compliant surface finish, electroless Au/Ni plating allows manufacturers to meet stringent environmental regulations while ensuring the durability and reliability of their products. By understanding the plating process, factors affecting its quality, and its advantages over other surface finishes, engineers and designers can make informed decisions when selecting the most suitable surface finish for their specific applications.

As the demand for high-performance electronic components continues to grow, electroless Au/Ni plating is expected to play an increasingly important role in enabling the development of advanced technologies and products that can withstand the challenges of modern industries.

Leave a Reply