Introduction to Gerber Formats

Gerber format is a standard file format used in the electronic industry for describing the printed circuit board (PCB) designs and schematics. It is a vector image file format that contains information about the copper layers, solder mask, legend, and drill holes of a PCB. Gerber files are essential for PCB fabrication as they provide the necessary information to manufacture the board.

History of Gerber Formats

The Gerber format was originally developed by the Gerber Systems Corp. in the 1960s as a means of controlling their vector photoplotters. It quickly became the de facto standard format for PCB design data exchange. In 1998, Ucamco took over the development and standardization of the Gerber format.

Importance of Gerber Formats in PCB Design and Manufacturing

Gerber files are crucial in PCB design and manufacturing because they contain all the necessary information required to fabricate a PCB. The PCB fabrication process involves several steps, including:

-

PCB Design: The PCB design is created using Electronic Design Automation (EDA) software, such as Altium Designer, Eagle, or KiCad.

-

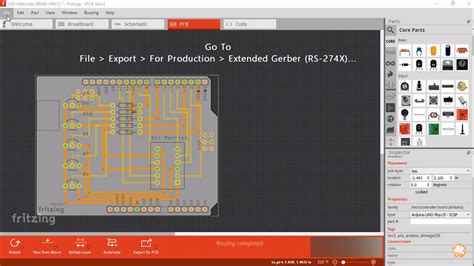

Gerber File Generation: Once the PCB design is complete, the EDA software generates Gerber files for each layer of the PCB.

-

PCB Fabrication: The Gerber files are sent to the PCB manufacturer, who uses them to create the physical PCB.

Without Gerber files, it would be impossible to manufacture a PCB accurately and consistently.

Types of Gerber Formats

There are several types of Gerber formats, each serving a specific purpose in the PCB fabrication process.

RS-274D

RS-274D, also known as Gerber D-Code format, is the oldest and most basic Gerber format. It uses a set of predefined apertures (D-Codes) to describe the PCB features. Each D-Code represents a specific shape, such as a circle, rectangle, or oblong.

| D-Code | Shape | Size (mm) |

|---|---|---|

| D10 | Circle | 0.5 |

| D11 | Rectangle | 1.0 x 2.0 |

| D12 | Oblong | 0.8 x 1.6 |

RS-274D has several limitations, such as the lack of support for advanced features like embedded apertures and the need for a separate aperture list file.

RS-274X

RS-274X, also known as Extended Gerber or Gerber X format, is an improvement over the RS-274D format. It introduced several new features, such as:

- Embedded aperture definitions

- Aperture macros

- Polarity control

- Interpolation modes

These features allow for more compact and efficient Gerber files, eliminating the need for separate aperture list files.

| Function | RS-274D | RS-274X |

|---|---|---|

| Apertures | Predefined list | Embedded |

| Macros | Not supported | Supported |

| Polarity | Limited support | Full support |

Gerber X2

Gerber X2 is the latest revision of the Gerber format, introduced in 2014. It builds upon the RS-274X format and adds several new features, such as:

- Attributes: Allows for the inclusion of metadata, such as part numbers, revisions, and materials.

- Nested step and repeat: Enables the creation of complex patterns and arrays.

- Pads and vias: Provides a more intuitive way to define pads and vias.

Gerber X2 aims to improve the communication between PCB designers and manufacturers, reducing the potential for errors and misinterpretations.

Gerber File Structure

A typical Gerber file consists of several sections, each serving a specific purpose.

Header

The header section contains information about the file format, such as the file name, creation date, and format specification.

G04 Ucamco ex. 1: Minimal NEW*

%TF.FileFunction,Copper,L1,Top*%

%TF.Part,Single*%

%FSLAX25Y25*%

%MOMM*%

%ADD10C,0.5*%

Aperture Definitions

The aperture definitions section defines the shapes and sizes of the apertures used in the file. In RS-274X and Gerber X2 formats, the aperture definitions are embedded within the file.

%ADD10C,0.5*%

%ADD11R,1.0X2.0*%

%ADD12O,0.8X1.6*%

Data Blocks

The data blocks section contains the actual PCB design data, such as the coordinates and aperture commands for each feature.

G01*

D10*

X1000Y1000D03*

X2000Y2000D03*

D11*

X3000Y1500D03*

X4000Y2500D03*

End of File

The end of file section marks the end of the Gerber file.

M02*

Best Practices for Creating Gerber Files

To ensure the accuracy and reliability of your Gerber files, follow these best practices:

- Use the latest Gerber format (Gerber X2) whenever possible.

- Include all necessary layers, such as copper, solder mask, and silkscreen.

- Provide a clear and concise readme file with any additional information or instructions.

- Verify your Gerber files using a Gerber viewer or DFM (Design for Manufacturability) tool.

- Communicate with your PCB manufacturer to ensure they can work with your Gerber files and understand your requirements.

Common Issues and Solutions

Incorrect Aperture Definitions

Incorrect aperture definitions can lead to manufacturing errors, such as missing or incorrectly sized features.

Solution: Double-check your aperture definitions and ensure they match the intended design.

Missing Layers

Missing layers can result in an incomplete PCB, lacking essential features like solder mask or silkscreen.

Solution: Verify that all necessary layers are included in your Gerber files.

Incorrect File Extensions

Using incorrect file extensions can cause confusion and delays in the manufacturing process.

Solution: Use the correct file extensions for each layer, as specified by your PCB manufacturer.

Incompatible File Formats

Some PCB manufacturers may not support older Gerber formats, such as RS-274D.

Solution: Use a newer Gerber format, such as RS-274X or Gerber X2, and check with your manufacturer for their preferred format.

FAQ

What is the difference between RS-274D and RS-274X Gerber formats?

RS-274X is an improved version of the RS-274D format, offering features like embedded aperture definitions, aperture macros, and polarity control. RS-274X eliminates the need for separate aperture list files and allows for more compact and efficient Gerber files.

Can I use different Gerber formats for different layers?

While it is possible to use different Gerber formats for different layers, it is generally recommended to use the same format for all layers to ensure compatibility and avoid potential issues during manufacturing.

How can I verify my Gerber files before sending them to a PCB manufacturer?

You can use a Gerber viewer or DFM (Design for Manufacturability) tool to verify your Gerber files. These tools can help you identify potential issues, such as incorrect aperture definitions or missing layers, before sending your files to the manufacturer.

What should I include in a readme file for my Gerber files?

A readme file should include any additional information or instructions that are not conveyed in the Gerber files themselves. This can include the PCB design software used, the Gerber format version, layer descriptions, and any special requirements or considerations for manufacturing.

How do I choose the right PCB manufacturer for my Gerber files?

When choosing a PCB manufacturer, consider factors such as their experience, manufacturing capabilities, and support for your preferred Gerber format. Communicate with potential manufacturers to ensure they can work with your Gerber files and understand your requirements.

Conclusion

Gerber formats are essential for accurate and consistent PCB design and manufacturing. By understanding the different types of Gerber formats, their structure, and best practices for creating and verifying Gerber files, you can ensure that your PCB designs are effectively communicated to manufacturers and fabricated to your specifications. Staying up-to-date with the latest Gerber format developments and maintaining clear communication with your PCB manufacturer will help streamline the manufacturing process and minimize potential issues.

Leave a Reply