Introduction to IC block removal

Integrated Circuit (IC) blocks are essential components of Printed Circuit Boards (PCBs) that perform various functions in electronic devices. However, there may be instances when you need to remove an IC block from a PCB, such as for replacement, repair, or upgrades. This article will guide you through the process of safely and effectively removing an IC block from a PCB.

What is an IC Block?

An IC block, also known as an IC chip or package, is a small electronic component that contains a complex circuit designed to perform specific functions within an electronic device. These functions can range from simple logic operations to complex processing tasks. IC blocks are typically mounted on a PCB using various techniques, such as through-hole or surface-mount technology (SMT).

Reasons for Removing an IC Block

There are several reasons why you may need to remove an IC block from a PCB:

- Replacing a faulty or damaged IC block

- Upgrading to a newer or more efficient IC block

- Modifying the circuit design of the PCB

- Salvaging a specific IC block for use in another project

Tools and Materials Required for IC Block Removal

Before attempting to remove an IC block from a PCB, it’s essential to gather the necessary tools and materials. Here’s a list of items you’ll need:

- Soldering iron with adjustable temperature control

- Desoldering pump or solder sucker

- Desoldering wick or braid

- Tweezers or pliers

- Flux (optional)

- Isopropyl alcohol for cleaning

- Safety glasses and gloves for protection

Choosing the Right Soldering Iron

When selecting a soldering iron for IC block removal, consider the following factors:

- Wattage: A soldering iron with a wattage between 30W and 50W is suitable for most IC block removal tasks.

- Temperature control: An adjustable temperature control feature allows you to set the appropriate temperature for the specific IC block and PCB materials.

- Tip size and shape: Choose a tip that is appropriate for the size of the IC block and the PCB pads. A chisel or blade tip is often preferred for desoldering tasks.

Step-by-Step Guide to Removing an IC Block

Follow these steps to safely remove an IC block from a PCB:

Step 1: Preparation

- Ensure that the PCB is clean and free from dirt or debris.

- Identify the IC block that needs to be removed and locate its pins or leads.

- Put on safety glasses and gloves to protect yourself from potential burns or injuries.

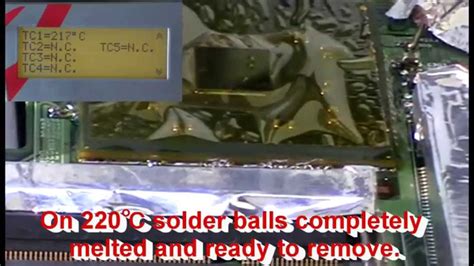

Step 2: Applying Heat

- Set your soldering iron to the appropriate temperature for the IC block and PCB materials (usually between 300°C and 400°C).

- Apply the soldering iron tip to the pins or leads of the IC block, ensuring that all the solder joints are heated evenly.

- Gently move the soldering iron tip around the pins to distribute the heat and melt the solder.

Step 3: Removing Solder

- While keeping the soldering iron tip in contact with the pins, use a desoldering pump or solder sucker to remove the melted solder from the joints.

- Alternatively, you can use desoldering wick or braid to absorb the melted solder by placing it on the pins and pressing the soldering iron tip against it.

- Repeat the process until most of the solder is removed from the pins.

Step 4: Lifting the IC Block

- Once the solder has been removed, gently lift the IC block using tweezers or pliers.

- If the IC block is still stuck, apply a small amount of flux to the pins and reheat them with the soldering iron to help loosen the connection.

- Carefully remove the IC block from the PCB, ensuring that you do not damage the PCB pads or traces.

Step 5: Cleaning and Inspection

- Clean the PCB pads and surrounding area with isopropyl alcohol to remove any residual flux or solder.

- Inspect the PCB for any damage, such as lifted pads or broken traces. If necessary, repair the PCB before proceeding with any further work.

Tips and Tricks for Successful IC Block Removal

- Always use the appropriate tools and materials for the job to minimize the risk of damage to the PCB or the IC block.

- Ensure that the soldering iron tip is clean and well-tinned before use to promote efficient heat transfer.

- Apply heat evenly to all the pins of the IC block to avoid thermal stress and potential damage.

- Use flux to help the solder flow more easily and to prevent oxidation during the desoldering process.

- Be patient and take your time when removing the solder and lifting the IC block to minimize the risk of damage.

Common Challenges and Solutions

Challenge 1: Difficulty Removing All the Solder

If you find it challenging to remove all the solder from the IC block pins, try the following solutions:

- Use a larger soldering iron tip or increase the temperature slightly to improve heat transfer.

- Apply a small amount of flux to the pins to help the solder flow more easily.

- Use a combination of desoldering pump and desoldering wick to remove the solder effectively.

Challenge 2: Damaged PCB Pads or Traces

If you accidentally damage the PCB pads or traces during the IC block removal process, consider these solutions:

- Use a fine-tipped soldering iron and a small amount of solder to repair any lifted or damaged pads.

- For broken traces, carefully scrape away the solder mask and use a thin wire to bridge the gap between the broken trace ends.

- If the damage is extensive, consider using a PCB repair kit or consulting a professional PCB repair service.

Alternatives to Manual IC Block Removal

If you find manual IC block removal too challenging or time-consuming, there are alternative methods available:

Hot Air Rework Station

A hot air rework station uses a focused stream of hot air to melt the solder and remove the IC block. This method is particularly useful for surface-mounted IC blocks and can be less likely to cause damage to the PCB compared to manual removal.

Desoldering Station

A desoldering station combines a soldering iron with a vacuum pump to simultaneously melt the solder and remove it from the pins. This method is more efficient than manual removal and can be particularly useful for through-hole IC blocks.

Frequently Asked Questions (FAQ)

-

Q: Can I reuse an IC block after removing it from a PCB?

A: In most cases, yes. However, ensure that the IC block is not damaged during the removal process and that it is compatible with the new PCB or application. -

Q: What should I do if I accidentally damage the PCB during IC block removal?

A: Assess the extent of the damage and determine whether it can be repaired using the methods mentioned in the “Common Challenges and Solutions” section. If the damage is severe, consider replacing the PCB or consulting a professional repair service. -

Q: Can I use a regular soldering iron for IC block removal?

A: While a regular soldering iron can be used, it is recommended to use a soldering iron with adjustable temperature control and a suitable tip size and shape for better results and to minimize the risk of damage. -

Q: How do I know if I have removed all the solder from the IC block pins?

A: Visually inspect the pins using a magnifying glass or microscope to ensure that all the solder has been removed. You can also gently wiggle the IC block to check if it is loose and ready to be lifted. -

Q: Is it necessary to use flux when removing an IC block?

A: While flux is not always necessary, it can help the solder flow more easily and prevent oxidation during the desoldering process, making the removal process more efficient and reducing the risk of damage to the PCB or IC block.

Conclusion

Removing an IC block from a PCB can be a delicate and challenging process, but with the right tools, materials, and techniques, it can be done safely and effectively. By following the step-by-step guide and considering the tips, tricks, and alternative methods outlined in this article, you can successfully remove an IC block from a PCB for replacement, repair, or salvage purposes. Remember to prioritize safety, take your time, and practice patience to achieve the best results.

| Step | Description | Tools Required |

|---|---|---|

| 1 | Preparation | Safety glasses, gloves |

| 2 | Applying Heat | Soldering iron |

| 3 | Removing Solder | Desoldering pump, desoldering wick |

| 4 | Lifting the IC Block | Tweezers, pliers |

| 5 | Cleaning and Inspection | Isopropyl alcohol |

Leave a Reply