Introduction to Microammeter Circuits

A microammeter is an essential tool for measuring small electric currents, typically in the range of microamperes (μA). These instruments find applications in various fields, including electronics, research, and industrial settings. In this article, we will explore the design and construction of a simple microammeter circuit that can be built using readily available components.

What is a Microammeter?

A microammeter is a sensitive current-measuring device capable of detecting and measuring currents in the microampere range. Unlike conventional ammeters, which measure currents in the milliampere (mA) or ampere (A) range, microammeters are specifically designed to handle much smaller currents.

Applications of Microammeters

Microammeters find use in a wide range of applications, such as:

- Testing and troubleshooting low-current electronic circuits

- Measuring leakage currents in capacitors and other components

- Monitoring the output of sensors and transducers

- Investigating the electrical properties of materials

- Calibrating and verifying the performance of other measuring instruments

Designing a Microammeter Circuit

To design a simple microammeter circuit, we need to understand the basic principles behind current measurement and the components required to build the circuit.

Current Measurement Principles

Current measurement is based on the principle of Ohm’s law, which states that the voltage across a resistor is directly proportional to the current flowing through it. Mathematically, Ohm’s law is expressed as:

V = I × R

Where:

– V is the voltage across the resistor (in volts)

– I is the current flowing through the resistor (in amperes)

– R is the resistance of the resistor (in ohms)

By measuring the voltage drop across a known resistor and applying Ohm’s law, we can determine the current flowing through the circuit.

Components Required

To build a simple microammeter circuit, you will need the following components:

- Operational amplifier (op-amp)

- Resistors

- Capacitors

- Potentiometer

- Diodes

- Battery or Power Supply

- Printed circuit board (PCB) or breadboard

- Connectors and wires

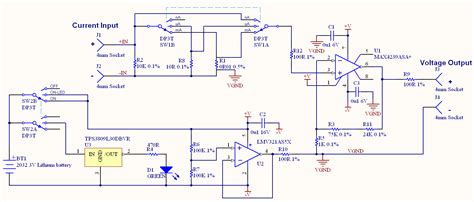

Circuit Design

The core of the microammeter circuit is an operational amplifier (op-amp) configured as a current-to-Voltage Converter. The op-amp amplifies the small current signal and converts it into a proportional voltage that can be easily measured.

Here’s a simplified schematic of the microammeter circuit:

+V

|

|

+-+

| |

| | R1

| |

+-+

|

|

Vin ---+--- Vout

|

|

+-+

| |

| | R2

| |

+-+

|

|

GND

In this circuit:

– Vin is the input voltage from the current-sensing resistor

– R1 and R2 form a Voltage Divider to set the gain of the op-amp

– Vout is the amplified output voltage proportional to the input current

The values of R1 and R2 determine the gain of the op-amp and, consequently, the sensitivity of the microammeter. The gain can be calculated using the following formula:

Gain = 1 + (R2 / R1)

By carefully selecting the values of R1 and R2, you can adjust the range and resolution of the microammeter to suit your specific measurement needs.

Calibration and Scaling

Once the microammeter circuit is assembled, it needs to be calibrated to ensure accurate readings. Calibration involves applying known currents to the input and adjusting the potentiometer to obtain the desired output voltage.

To calibrate the microammeter:

- Connect a variable current source (e.g., a adjustable power supply with a series resistor) to the input of the microammeter.

- Set the current source to a known value within the desired measurement range.

- Adjust the potentiometer until the output voltage corresponds to the expected value based on the input current and the op-amp gain.

- Repeat steps 2 and 3 for different input currents to verify the linearity and accuracy of the microammeter.

After calibration, you can create a scale or lookup table that relates the output voltage to the corresponding input current. This scale will allow you to directly read the current in microamperes based on the measured output voltage.

Constructing the Microammeter

With the circuit design and calibration process understood, let’s walk through the steps to construct the microammeter.

Step 1: Gather the Components

Collect all the necessary components listed in the “Components Required” section. Make sure you have the correct values for the resistors and capacitors based on your desired measurement range and circuit characteristics.

Step 2: Assemble the Circuit

You can assemble the microammeter circuit on a printed circuit board (PCB) or a breadboard, depending on your preference and the intended permanence of the project.

- Begin by placing the op-amp on the PCB or breadboard.

- Connect the power supply pins of the op-amp to the appropriate voltage rails (positive and negative supply or ground).

- Place the resistors R1 and R2 according to the schematic, forming the voltage divider at the non-inverting input of the op-amp.

- Connect the potentiometer in series with R1 to allow for calibration adjustments.

- Add the input and output connections as shown in the schematic.

- Include any additional components, such as capacitors for filtering or diodes for protection, as required by your specific design.

Step 3: Soldering (Optional)

If you are using a PCB, you will need to solder the components in place. Follow these guidelines for soldering:

- Use a soldering iron with an appropriate tip size and temperature.

- Apply heat to the pad and the component lead simultaneously.

- Feed solder into the joint while maintaining heat.

- Remove the soldering iron and allow the joint to cool naturally.

- Inspect the soldered joint for a clean and shiny appearance.

Step 4: Testing and Troubleshooting

After assembling the microammeter circuit, it’s essential to test its functionality and troubleshoot any issues that may arise.

- Double-check all connections to ensure they are secure and correct.

- Apply power to the circuit and verify that the op-amp is receiving the proper supply voltages.

- Connect a known current source to the input and measure the output voltage using a digital Multimeter (DMM).

- Compare the measured output voltage with the expected value based on the input current and the op-amp gain.

- If the output voltage is incorrect or unstable, recheck the connections, component values, and power supply.

- Use an oscilloscope, if available, to check for any noise or oscillations in the output signal.

Step 5: Calibration

Perform the calibration process as described in the “Calibration and Scaling” section. Adjust the potentiometer until the microammeter provides accurate readings across the desired measurement range.

Using the Microammeter

Once your microammeter is constructed and calibrated, you can start using it to measure small currents in various applications.

Connecting the Microammeter

To measure current using the microammeter:

- Ensure the circuit under test is powered off.

- Identify the location in the circuit where you want to measure the current.

- Break the circuit at that point and connect the microammeter in series.

- Power on the circuit and observe the microammeter’s output voltage.

- Convert the output voltage to current using the calibrated scale or lookup table.

Remember to always connect the microammeter in series with the circuit under test. Connecting it in parallel can damage the microammeter and lead to inaccurate readings.

Measuring Tips

Here are some tips to help you obtain accurate and reliable measurements with your microammeter:

- Ensure the microammeter is calibrated before taking measurements.

- Select the appropriate measurement range based on the expected current levels.

- Avoid overloading the microammeter by measuring currents beyond its maximum rating.

- Use shielded cables or twisted pairs to reduce electromagnetic interference and noise pickup.

- Allow the microammeter to warm up and stabilize before taking critical measurements.

- Take multiple readings and average them to minimize the impact of random errors.

By following these tips and understanding the limitations of your microammeter, you can ensure accurate and reliable current measurements in your projects and experiments.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a microammeter and a standard ammeter?

A: A microammeter is designed to measure very small currents in the microampere (μA) range, while a standard ammeter measures currents in the milliampere (mA) or ampere (A) range. Microammeters are more sensitive and have a higher resolution than standard ammeters. -

Q: Can I use a microammeter to measure voltage?

A: No, a microammeter is specifically designed to measure current. To measure voltage, you would need a voltmeter or a multimeter with a voltage measurement function. -

Q: How do I protect my microammeter from overload or damage?

A: To protect your microammeter, always ensure that the current being measured is within the specified range of the instrument. You can also include protective components such as fuses or Current-Limiting Resistors in series with the microammeter to prevent excessive current flow. -

Q: Can I build a microammeter with a digital output instead of an analog output?

A: Yes, you can modify the microammeter circuit to include an analog-to-digital converter (ADC) and a digital display or interface. This would allow you to directly read the current in digital format and potentially interface the microammeter with a computer or data logging system. -

Q: Are there any safety precautions I should take when using a microammeter?

A: When using a microammeter, always follow proper electrical safety practices. Ensure the circuit under test is powered off before connecting or disconnecting the microammeter. Avoid touching exposed conductors or live parts of the circuit. If measuring currents in high-voltage or high-power circuits, use appropriate personal protective equipment (PPE) and follow established safety protocols.

Conclusion

In this article, we explored the design, construction, and use of a simple microammeter circuit. By understanding the principles of current measurement, selecting the appropriate components, and following the calibration and usage guidelines, you can build a functional microammeter for measuring small currents in various applications.

Remember to prioritize safety, adhere to the instrument’s specifications, and take necessary precautions when working with electrical circuits. With a well-constructed and calibrated microammeter, you can accurately measure and analyze low-current signals, enabling you to troubleshoot, optimize, and innovate in your electronics projects.

Happy measuring!

Leave a Reply