Introduction to PCB Assembly in Colorado

Printed circuit board (PCB) assembly is a key process in the electronics manufacturing industry. It involves soldering electronic components onto PCBs using surface mount technology (SMT) and/or through-hole technology (THT). Colorado has emerged as a major hub for PCB assembly in the United States, driven by the following factors:

- Presence of a vibrant high-tech industry centered around aerospace, defense, telecom, medical devices, etc. which require electronics assembly services.

- Excellent infrastructure and operating environment which attracts investments. This includes top engineering talent from the state’s research institutes and universities.

- Favorable tax incentives offered by the state government to promote manufacturing activity.

- Proximity to high-tech hubs in Silicon Valley and electronics supply chains in Asia which makes logistics efficient.

This article provides an overview of the top 5 PCB assembly companies in Colorado based on factors like capabilities, experience, certifications and customer reviews.

Top 5 PCB Assembly Companies in Colorado

1. SigmaTron International

SigmaTron has been providing electronics manufacturing services for over 50 years. The company operates an extensive 170,000 sq. ft. facility in El Paso County, Colorado dedicated to PCB assembly and box build.

Capabilities

- SMT assembly with lines from Fuji, Universal, and Assembleon

- Complex board assembly with 01005 components, 0.3mm pitch BGAs, Press Fit

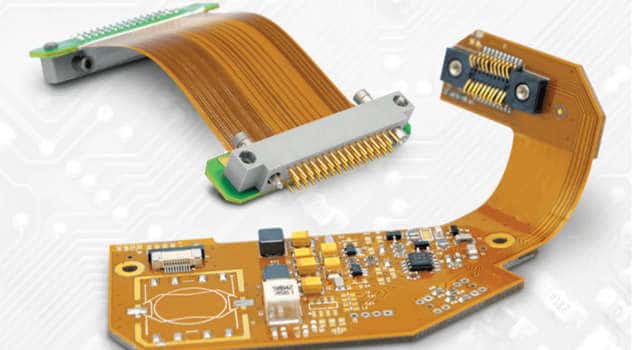

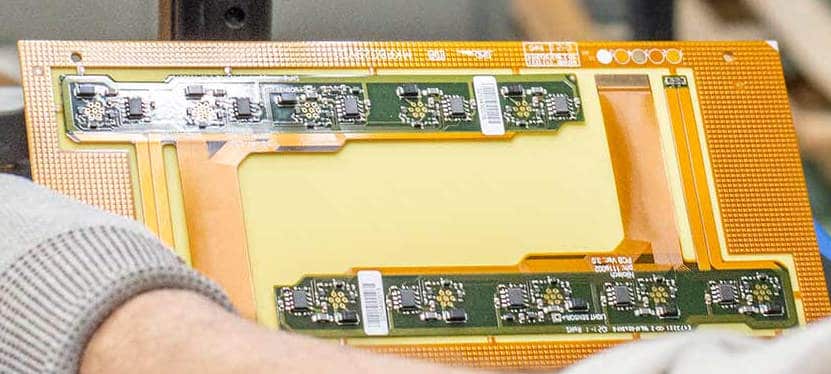

- Flexible and rigid-flex PCB assembly

- DFM analysis and test engineering services

- Full box build, rack integration, and product assembly

Industries Served

Aerospace, Defense, Industrial, Medical, Semiconductor

Certifications

ISO9001, ISO13485, AS9100D, IPC Class 2, 3

Sample Customers

Ball Aerospace, L3Harris, Emerson, Hewlett-Packard, Agilent

Location – El Paso County, Colorado, USA

2. Creation Technologies

Founded in 1991, Creation Technologies operates 18 manufacturing sites across the USA, including a major facility in Denver, Colorado dedicated to electronics assembly.

Capabilities

- SMT, thru-hole and mixed technology assembly

- 01005 chip components, 0.4mm pitch, 0.3mm BGA

- Multi-up PCB configurations

- Conformal coating and potting

- Automated optical inspection

- Functional test and ICT

Industries

Medical, Industrial Equipment, Aerospace, Transportation, IoT

Certifications

ISO13485, ISO9001, IPC Class 2, 3, ITAR Registered

Sample Customers

Medtronic, Abbott, Waters, Emerson, Rockwell, Schneider, Zebra

Location – Denver, Colorado

3. Innovative Circuits

Located in Alamosa, Colorado, Innovative Circuits provides quickturn PCB assembly catering to prototyping and medium volume production needs.

Capabilities

- SMT, thru-hole and mixed assembly

- Quickturn assemblies from 24-48 hours

- IPC Class 2 and Class 3 workmanship standards

- Automated optical inspection (AOI)

- Flexible and rigid-flex PCBs

- Design and DFM review services

Industries

Aerospace, Defense, Medical, Communications, Industrial

Certifications

ISO 9001:2015, ITAR Registered

Sample Customers

Ball Aerospace, L3Harris, Lockheed Martin, Intel, Emerson

Location – Alamosa, Colorado

4. Saline Lectronics

Saline Lectronics has over 25 years of experience delivering high mix, low volume PCB assemblies for aerospace, defense and high-rel markets from their facility in Grand Junction, CO.

Capabilities

- Prototyping, quickturns, medium and high volume

- 01005 passives, 0.4mm pitch, 0.5mm BGA assembly

- IPC Class 2, Class 3 and space rated assemblies

- Rigid, rigid-flex, and multi-layer boards

- NADCAP certified processes

Industries

Space, Avionics, Military, Medical, Downhole

Certifications

AS9100D, ISO9001:2015, IPC-A-610 Class 2/3

Sample Customers

Ball Aerospace, L3Harris, Lockheed Martin, Honeywell, Essex

Location – Grand Junction, Colorado

5. Bitwise Solutions

Located near Denver, Bitwise Solutions provides advanced PCB assembly focused on high-reliability, mission-critical applications since 1999.

Capabilities

- High mix, low to medium volume assembly

- MIL-PRF-31032 and space rated assembly

- 01005 components, 0.4mm pitch, 0.3mm BGA

- IPC Class 3 and NASA workmanship standards

- Soldering to MIL-STDs

Industries

Aerospace, Space Systems, Avionics, Defense, Medical

Certifications

AS9100D, ISO9001:2015, IPC Class 2, 3, J-STD-001

Sample Customers

Lockheed Martin, Northrop Grumman, Raytheon, Boeing, Juniper Networks

Location – Westminster, Colorado

This covers 5 leading PCB assembly providers in Colorado that offer a range of solutions from quickturn prototyping to high-reliability, defense-grade assembly capabilities. Their strategic location, engineering expertise, and customer-focused approach makes them ideal partners for electronics product realization and contract manufacturing.

Key Considerations for Selecting a PCB Assembly Partner

Here are some important factors companies should evaluate when choosing a PCB assembly partner in Colorado or elsewhere:

Technical Capabilities

- What assembly technologies are supported – SMT, THT, mixed, etc.?

- How small of components, fine pitch ICs, BGAs etc. can be handled?

- What size and type of boards are supported? Rigid, flex, rigid-flex, multilayer, etc.

- Are engineers available for DFM analysis and test development?

- What test capabilities are available – ICT, AOI, functional, environmental?

Quality and Certifications

- Is the facility certified for standards like ISO13485, AS9100, IPC, ITAR, etc.?

- What IPC workmanship standards are followed? Class 2, Class 3, Class 3/A?

- Is an ESD-controlled environment maintained?

- How are processes validated and what quality metrics are tracked?

Volume Production

- What is the annual assembly capacity? Can they support low to medium volumes?

- How fast can they turnaround prototypes and quick-turn assemblies?

- Do they offer process optimization, test, inspection at each stage?

Supply Chain

- Can they procure components required or do I need to supply?

- How is inventory managed – stocking programs, JIT, consigned parts?

- Can they take responsibility for supplier quality management?

Program Management

- What is the customer communication process during builds?

- How well are product change notices, obsolescence and other risks managed?

- Can they provide detailed assembly and test reports?

Location and Security

- Where are their production facilities located?

- Are the facilities secure with restricted access controls?

- Is ITAR registration required based on my product compliance needs?

Carefully evaluating PCB assembly partners against these criteria minimizes project execution risks and results in high-quality outcomes.

Key Steps in the PCB Assembly Process

The typical printed circuit board assembly process involves the following key steps:

1. Design for Manufacturing: Upfront collaboration between designer and assembler to design products optimized for manufacturability and testability.

2. Sourcing Components: Procurement of components required as per bill of materials – may be supplied by customer or purchased by assembler.

3. Solder Paste Stencil: Laser cut metal stencil for applying paste precisely on PCB pads.

4. Solder Paste Printing: Solder paste deposited on pads through the stencil openings before component placement.

5. Pick and Place Assembly: Robotic pick and place system picks components and places accurately on board.

6. Reflow Soldering: SMT components soldered to board in conveyor ovens through thermal reflow process.

7. Conformal Coating: Protective coating applied to shield boards from moisture, debris etc.

8. AOI and Testing: Automated optical inspection and electrical testing performed to catch assembly defects.

9. Box Build: Final mechanical assembly integrating boards, connectors, cables, housings etc.

10. Final functional test: Validation of fully built system versus customer requirements.

Understanding these assembly steps allows for better design choices and visibility into the manufacturing process.

Latest Trends in Printed Circuit Board Assembly

Here are some key trends influencing PCB assembly currently:

Miniaturization

As devices get more compact, components are shrinking. 01005 chips, 0.30mm pitch ICs and microBGAs are becoming more common. This requires advanced assembly equipment.

Higher Density

Board real estate is shrinking. To maximize space, assemblers are placing components on both sides and providing high density interconnects.

Improved Yields

With miniaturization, optimizing yield is critical. Assemblers leverage AI-based inspection, strict process control and analyses to improve yields.

Flex/Rigid Flex

Flexible PCB sections enable conformity to product shape or mechanical movement. Assembling flex and rigid-flex boards requires specialized processes.

Functional Integration

More functionality is being integrated onto boards through advanced packaging approaches like Multi-Chip Modules (MCMs).

Higher Speeds

Data rates are increasing in products. This demands precision assembly to maintain signal integrity at microwave frequencies.

Leading PCB assembly partners proactively adopt new processes aligned with these trends to deliver innovative, high-performance electronics solutions.

How Partnering with an EMS Provider Supports Product Success

Partnering with a full-service electronics manufacturing services (EMS) provider that offers PCB assembly, can deliver significant advantages for your product programs:

Faster Time-to-Market

- Leverage EMS industry knowledge to design for optimal manufacturing and test.

- Source components while product is being designed to avoid delays.

- Flexible prototype builds and quick-turn assembly services.

Lower Total Cost

- Strategic component sourcing through the EMS’s global supply chain.

- Volume pricing on components.

- Assistance managing inventory and reducing waste.

High Quality

- Consistent processes with continuous improvement programs.

- IPC workmanship and rigorous testing.

- Quality metrics visible to customers at each step.

Better Focus

- EMS takes care of manufacturing details so you can focus on product innovation.

- Seamless transfer from R&D to production.

Supply Chain Resilience

- Dual sourcing of components.

- Established supplier relationships to manage disruptions.

- Distribution centers close to your facilities for JIT delivery.

Choosing the right EMS partner provides access to expertise and resources critical for bringing reliable, high-quality connected products to market quickly and cost-effectively.

Frequently Asked Questions

Q: What certifications are most important for a PCB assembler to have?

Some of the most valuable certifications to look for in a PCB assembly partner include:

- IPC-A-610 – Industry standard for electronics assembly workmanship quality. Class 2 and 3 are common. Class 3/A denotes the highest quality level.

- IPC J-STD-001 – Joint industry standard for soldering processes like reflow, wave, hand, rework, repair etc. Critical for quality and reliability.

- ISO 9001 – Confirms the company’s quality management system is standardized and follows best practices.

- ISO 13485 – For medical devices, this denotes processes meet stringent regulatory requirements.

- AS 9100 – Aerospace standard indicating high-reliability processes for defense and avionics.

- ITAR Registration – Required for companies handling sensitive defense or space-related electronics controlled under ITAR regulations.

Q: How can I estimate costs for PCB assembly?

While getting a final price quote requires getting details from the assembler, here are some helpful guidelines on factors impacting cost:

- Number of PCBs being assembled – unit price drops significantly with larger volumes due to efficiencies.

- BOM component costs – driven by total count and cost of individual parts. Component sourcing can help reduce this.

- Board size / complexity – more labor required for larger boards with higher component counts.

- Through-hole content – manual insertion is required so can increase costs versus just SMT.

- Any special processes like conformal coating, programming, testing etc.

- Lead times – quickturn and priority builds attract premiums.

As a rough estimate, an assembly shop rate is around $50 to $75 per hour. Complex boards can cost $1500+ at low volumes but drop below $100 each at mid to high volumes.

Q: What differences are there between IPC Class 2 and Class 3 PCB assembly?

The main differences between IPC Class 2 and Class 3 assembly are:

- Class 2 allows fewer visible defects and variance in workmanship criteria. Class 3 is more stringent.

- Class 2 tolerates some non-interconnect defects like discoloration that do not impact function. Class 3 does not.

- Class 3 requires more statistical process control and quality management rigor than Class 2.

- For solder fillets, Class 2 allows more variation in height and shape. In Class 3, height must be consistent.

- Class 2 permits some irregularities in part alignment. Class 3 requires uniform precise alignment.

- PCB pad etching defects are more permissible in Class 2 versus Class 3 which has essentially none allowed.

- Class 3 requires excellent surface cleanliness while Class 2 allows some flux residue.

So in summary, Class 3 represents the highest quality grade with essentially zero visible defects. It is typically used for high-reliability products where top performance and long-term reliability are critical. Class 2 is more of a commercial grade suitable for cost-sensitive consumer products.

Q: How can I ensure consistent quality across long production runs?

Some effective ways assemblers ensure consistency across long PCB production runs include:

- Statistical process control tracking key process parameters like temperature, humidity, paste volumes etc.

- Regular maintenance and calibration of equipment like reflow ovens.

- Analysis of defects and process drift from inspection and testing data to identify areas needing intervention.

- Sampling – testing and inspection of sample boards from start, middle and end of run to check stability.

- Qualification of critical components across multiple reels to minimize variation.

- Cycle time monitoring and optimization to avoid bottlenecks.

- Operator training reinforcement and workmanship certification.

- Updating documentation like drawings, work instructions in sync across production span.

- Change control procedures to carefully introduce any component, design or process changes.

- Quality team oversight with cross-functional focus on defect reduction and continuous improvement.

With rigorous quality practices implemented properly, long run consistency can match prototype and initial batch quality.

Q: What documentation do I need to provide to a PCB assembly shop?

Typical documentation required when outsourcing PCB assembly includes:

- Gerber Files – Fabrication layer images for assembly drawing reference.

- Bill of Materials (BOM) – Complete component list with reference designators, manufacturer part numbers and quantities.

- Pick-and-Place/Centroid File – Defines location and orientation of every part for surface mount assembly.

- Assembly Drawings – Top, bottom and side view drawings to illustrate assembly.

- Silkscreen/Soldermask Drawings – Show areas requiring soldermask and silkscreen application.

- Netlist – Connectivity matrix of components pin-to-pin and pin-to-pad.

- Stackup/Profile Drawings – For multilayer boards, shows lamination layers and sequence.

- AVL – Approved vendor list for components.

- Test/QC Requirements – Details checks to be performed during and after assembly.

Providing this comprehensive package ensures the assembler has all data needed to build your boards correctly.

Leave a Reply