Introduction

Printed circuit boards (PCBs) are essential components in nearly all modern electronic devices and equipment. They provide the underlying physical structure to mount components and interconnect them into functional circuits. For many electronics projects, getting PCB prototypes produced quickly is crucial for development and testing new designs rapidly. This capability is referred to as quick turn PCB fabrication.

Quick turn PCBs allow designers to obtain boards with very short lead times, often in just 24-48 hours. This accelerates the pace of prototyping and feedback. Understanding quick turn PCB manufacturing and how to best utilize it can help streamline the electronics design process.

What is Quick Turn PCB Production?

Quick turn PCB fabrication refers to the ability to get prototype or small-batch PCB orders produced very rapidly by a PCB manufacturer. Standard lead times in the industry are around 15 business days, but quick turn services can deliver in under 5 days. The fastest turnaround is next-day shipping of completed boards.

Some key characteristics of quick turn PCB production are:

- Extremely accelerated fabrication time allowing 1-2 day delivery

- Small quantities of 5, 10 or 15 boards typical

- Rush fabrication based on quick payment and quick design file delivery

- Higher costs than normal long-lead PCB production

- Restricted to simpler board technologies

Quick turn is focused on speed. It trades off advanced PCB capabilities for faster manufacturing by keeping design rules and features relatively straightforward.

Why Use Quick Turn PCBs?

Here are some typical situations where quick turn PCBs provide value:

- Faster prototyping – Validate designs and functions much sooner

- Accelerate testing – Start evaluation and debugging earlier

- Fix mistakes faster – Receiving boards rapidly reduces costly errors

- Meet deadlines – Quickly create boards needed to hit market windows

- Shorten design cycles – Crank through more prototype iterations and refinements

- Respond to demand – Get boards shipped almost immediately

For products with compressed development timelines, quick turn PCBs are indispensable to achieving short schedules. The high costs are offset by the ability to uncover issues early and ramp up production faster.

Quick Turn Manufacturing Process

Producing PCBs with extremely fast turnaround times requires streamlining of the fabrication process. Here is an overview of the quick turn manufacturing flow:

Simplified Design Rules

Only standard design rules are supported to avoid any manual checks or intervention. For instance, 10 mil minimum trace width and spacing.

Limited Technology Choices

Only the most common substrate materials, layer counts, trace densities, and copper weights are offered to avoid complex processing.

Front of Line Priority

Quick turn boards get top priority at each fabrication step to avoid waiting in queues.

Minimum Processing

Only essential processing steps are done, skipping any non-critical operations. For example, skipping soldermask or legend printing.

Reduced Testing

Electrical testing and inspection may be reduced or eliminated to save time.

Ship Immediately

Boards typically ship right after completion without waiting for scheduled shipments. Overnight express delivery.

This optimized workflow minimizes delays to hit extremely aggressive turnaround targets.

Quick Turn Design Guidelines

To qualify for quick turn fabrication and avoid delays, designs must adhere to a set of design guidelines:

- Simple 2-6 layer designs only

- Standard FR-4 substrate material

- No advanced substrates (e.g. Rogers)

- Common copper thickness (1 oz base, 0.5 to 1 oz external)

- Soldermask and silkscreen layers optional

- Maximum board sizes around 6” x 6” or 8” x 8”

- No complex board shapes or cutouts

- Minimum feature size 8-10 mil trace/space

- No impedance control or length matching required

- Avoid press-fit connectors and odd component packages

- Only leaded through-hole or basic SMT parts

- Standard lead times if using BGAs, microvias, blind/buried vias

By restricting the design to widely available capabilities, the PCB fabricator can shuffle the job quickly through their standard assembly line process without issue.

Cost Implications

The accelerated fabrication of quick turn PCBs comes at a premium cost. Some typical factors raising quick turn costs:

- Rush fees – Upfront surcharge for immediate turnaround

- Small volumes – No bulk discounts for prototype quantities

- Higher layer prices – Extra for fast multi-layer processing

- Reduced panel utilization – Lower efficiency from small boards

- Expedited materials – Premium pricing for getting materials fastest

- Additional labor – Around the clock staffing required

- Faster shipping – Overnight express delivery fees

- Potential scrap – Increased likelihood of unusable boards

The actual cost multiplier versus standard turn time can range from 2x to 10x depending on how fast the delivery is. One-day turnaround is the most expensive. The small number of boards limits the economies of scale.

Order Process Optimization

To further compress fabrication time, the design, order and delivery process must be optimized:

- Check design rules and Gerber files thoroughly before submitting orders

- Provide complete fabrication notes and instructions upfront for manufacturing

- Use online quoting tools to get target pricing established early

- Confirm manufacturing availability and qualify lead time

- Purchase order needs to be entered quickly after quoted for immediate processing

- Provide Gerber files, BOM, netlist, test procedures as soon as possible

- Use pre-paid accounts to avoid delays with purchase order paperwork and invoicing

- Have designer available for prompt responses if fabrication questions come up

- Provide shipping account and preferences for fastest delivery

Streamlining the peripheral administrative tasks allows manufacturers to start PCB panelization and fabrication as soon as the order is placed.

Comparison of Standard and Quick-Turn Processes

This table highlights the major differences between standard turn time PCB production and quick turn fabrication:

| Parameter | Standard Turn Time | Quick Turn |

|---|---|---|

| Lead Time | 10-15 days | 24-48 hours |

| Quantity | Medium-high | Prototyping |

| Cost | Lower | 2-10x higher |

| Layers | Any | 2-6 typical |

| Max Board Size | Large | Smaller |

| Features | Advanced OK | Only standard |

| Testing | Full electrical | Limited or none |

| Shipping | Bulk | Overnight express |

Applications Benefiting from Quick Turn PCBs

Here are some product development situations where quick turn PCB manufacturing provides important advantages:

Rapid Prototyping

With 1-2 day turnaround on boards, designers can quickly iterate through multiple revisions to test out different arrangements. Quick turn is ideal for prototyping phase.

Speed Up Qualification

Getting boards faster means qualification and testing can start sooner. This accelerates the development schedule.

Catch Errors Early

Mistakes can be identified while designs are still fluid, avoiding costly mid-stream changes.

Meet Deadlines

Fast boards help keep projects on pace to hit key milestones and market windows.

Accelerate Innovation

More experiments and design variations can progress in parallel using quick turn fabrication.

Shorten Design Cycles

Quick turn PCBs support faster concept-to-production development as each iteration happens quicker.

Just-in-Time Manufacturing

Get small batches of boards shipped immediately to build latest versions of products.

Respond to Urgent Needs

Produce boards rapidly to fulfill urgent field issues or customer change requests when needed.

Conclusion

Quick turn PCB fabrication provides crucial short lead time production of prototype boards needed to accelerate electronics product development. By streamlining order and fabrication processes, boards can be turned around in as little as 24 hours. Despite higher costs due to smaller quantities and rush fabrication, quick turn PCB capabilities can improve development schedules and time to market for innovative products. When used strategically, quick turn PCB manufacturing delivers valuable flexibility and responsiveness for companies pushing the boundaries with cutting-edge electronic designs.

Frequently Asked Questions

What is the fastest turnaround time for quick turn PCBs?

The fastest quick turn time is typically next-day fabrication and shipping. Some manufacturers also offer same-day shipping if orders are placed early enough in the day.

What are the limitations of quick turn PCB capabilities?

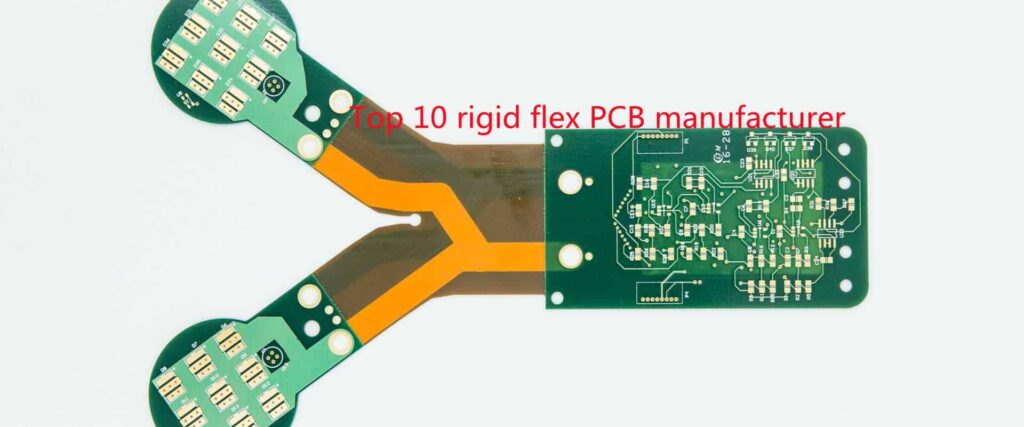

Quick turn boards cannot use advanced features like high layer counts, PTHs, blind/buried vias, HDI, or rigid-flex. Only standard FR4 substrates and simpler designs are allowed.

Does quick turn pricing change based on quantity?

Yes, larger quantities will cost proportionally less, but in general each PCB can be 2-4 times higher priced than normal turn time boards even at modest volumes.

How can I maximize the chance of success with quick turn boards?

Use a simple design, standard processes, avoid cutting edge features, follow design rules precisely, and review Gerber files thoroughly before submitting the order.

Are there ways to reduce the costs for quick turn PCBs?

Using fewer layers, smaller board sizes, eliminating soldermask/silkscreen, and ordering slightly larger quantities can help minimize quick turn costs somewhat.

Leave a Reply