Introduction to PCB Assembly

Printed circuit board (PCB) assembly is the process of soldering or assembling electronic components onto a PCB to create a functional electronic circuit. It is an important step in the electronics manufacturing supply chain after the PCB fabrication process. Some key facts about PCB assembly:

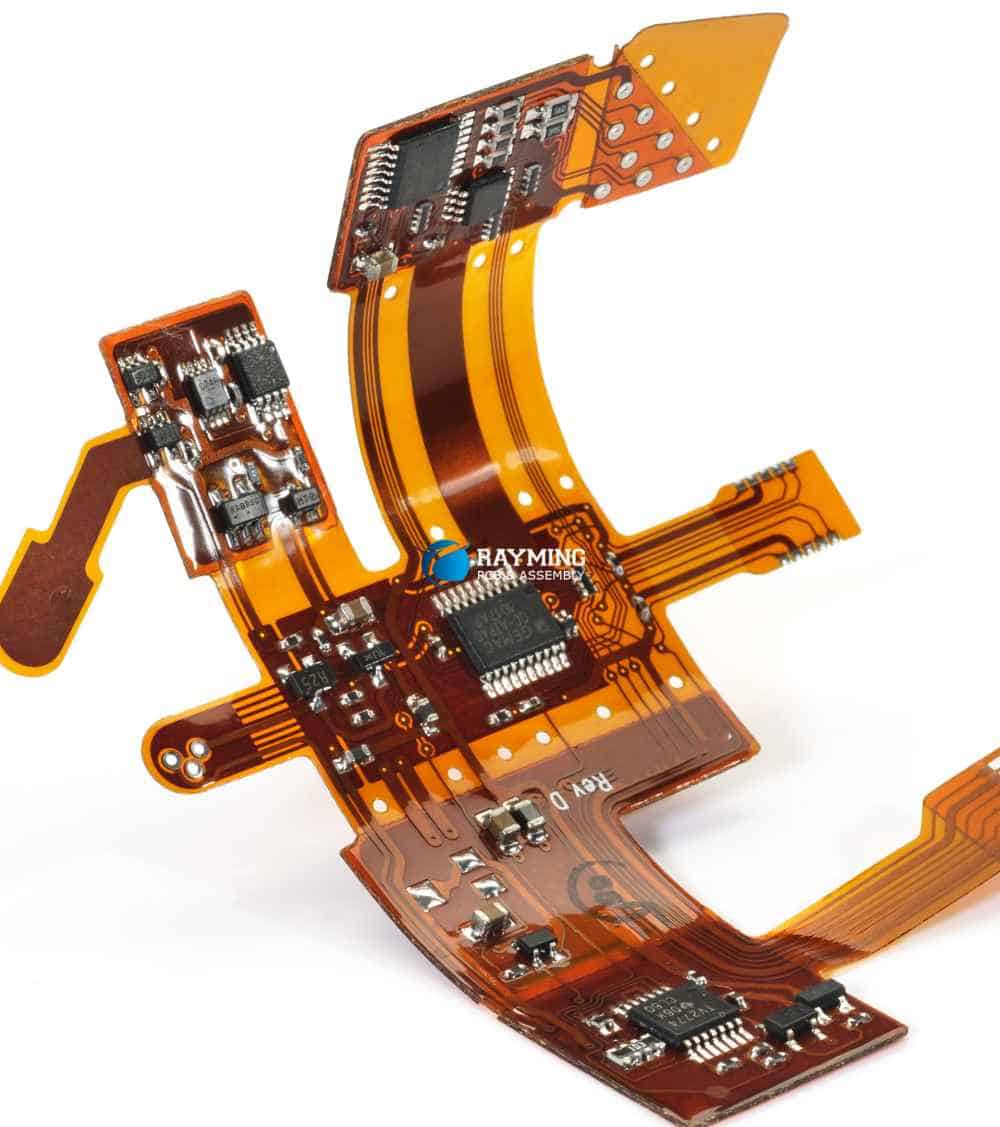

- PCB assembly involves placing components such as integrated circuits (ICs), resistors, capacitors, diodes etc. onto the bare PCB and soldering them in place using surface mount technology (SMT) or through-hole technology (THT).

- High speed pick and place machines, solder paste printers and reflow ovens are used for automated SMT assembly. Manual assembly may be used for quick-turn prototypes.

- PCB assembly can be performed in low, medium and high volume production. Complexity ranges from single-sided to multilayer boards.

- Important factors are assembly quality, speed, precision, flexibility, scalability and cost.

- Main application areas are consumer electronics, computers and peripherals, communications, industrial equipment, automotive etc.

PCB Assembly Manufacturing in China

China has become a major global manufacturing hub for electronic components and products over the last few decades. Some key facts about PCB assembly in China:

- China currently produces over 50% of the world’s consumer electronics products. A large majority of mobile phones, computers, TVs etc. contain PCBAs made in China.

- PCB assembly revenue in China was estimated to be over $100 billion in 2021. The PCB assembly industry employs millions of workers in China.

- There are thousands of PCB assembly manufacturers in China located mainly in the Guangdong, Jiangsu, Zhejiang and Shandong provinces which are major electronics hubs.

- These include large multinational companies with advanced facilities as well as numerous medium and smaller companies. There is a mix of dedicated and diverse electronics manufacturers.

- Main customer markets served are consumer electronics brands based in the USA, Europe and Asia. Many global electronics companies have products assembled in China.

- Manufacturing capabilities range from prototyping and low volume to very high volume assembly of up to hundreds of thousands of boards per month.

- Latest technologies like high density SMT lines, 3D AOI, robotic soldering etc. are used for quality and automation.

Factors to Consider when Selecting a PCB Assembly Partner

Selecting a good PCB assembly partner in China is crucial for OEMs and ODMs. Here are some key factors to consider:

Technical Capability

- Experience and expertise in PCB assembly process for the required production volume and complexity. This includes capabilities in SMT, THT, wave soldering, box build etc.

- Range of assembly capabilities – single-sided to multilayers boards, leaded and leadless components, fine-pitch ICs, BGAs, 01005 passive components etc.

- Knowledge of latest standards, techniques and technologies for quality assembly. Certifications like IPC 610 help.

- Engineering support for DFM, testing, inspection, repair etc. Helpful for prototyping and pre-production phases.

- Ability to work with various CAD tools and manufacturing files like Gerber, BOM, centroid data etc.

Production Capacity

- Suitable production capacity for required monthly volumes. Number of SMT lines, shift timings and workload are considerations.

- Scalability to adjust capacity up or down flexibly as needed. In-house or partner facilities help increase capacity.

- Consistent on-time delivery record even during peak volumes. Good inventory, sourcing and production planning.

Quality Systems

- Quality certifications such as ISO 9001, ISO 13485 etc. reflect standardized processes.

- Latest test and inspection equipment like 3D AOIs, x-ray inspection etc. help achieve quality standards.

- Process controls and checks in place during assembly, post-production testing, burn-in etc.

- Reliable and established suppliers used for components sourcing. Counterfeit component prevention.

- Traceability systems for tracking products and components used in individual boards.

Cost Factors

- Competitive pricing with detailed quotation covering materials, labor, overhead costs etc.

- Economies of scale by working with high volume manufacturers. Lower costs for higher volumes.

- Purchasing power of turnkey providers with financial leverage on components procurement. Saves on supply chain costs.

- Options to reduce costs like partial vs full turnkey assembly, supply chain alternatives etc.

Customer Service

- Good communication and project management skills. Fluent English speaking staff.

- Responsiveness to quote requests, product queries, tooling development, engineering changes etc.

- Experience supporting foreign customers. Understanding of global business culture.

- Helpful value-added services like procurement, prototyping, testing, logistics etc.

- Flexibility and willingness to meet special requirements or project needs.

Leading PCB Assembly Manufacturers in China

Here is an overview of some leading PCB assembly manufacturers in China with advanced capabilities and experience:

Foxconn

- Global giant in contract manufacturing and largest exporter from China.

- Massive production facilities in China located in Shenzhen, Chengdu, Zhengzhou etc. Over 1 million employees.

- Huge capacity with over hundreds of advanced SMT lines. Serves major electronics brands worldwide.

- Produces very high volumes – millions of iPhones, game consoles, TVs, PCs etc. Top quality standards.

- Full range of services from prototyping to volume assembly, testing, logistics etc.

Pegatron

- Major electronics manufacturing services company spun off from Asus. Revenues over $200 billion.

- Modern campuses in China in Shanghai, Kunshan and Suzhou. Around 100,000 employees.

- Broad PCB assembly capabilities for high complexity boards. Produces for major brands.

- Strong expertise in computing, networking, communications and consumer electronics.

- Extensive vertical integration for components production in-house.

Flex

- Global provider of design, engineering, manufacturing, and supply chain services and solutions.

- Numerous facilities in China across Beijing, Wuxi, Zhuhai etc. Employs over 200,000 staff worldwide.

- Broad expertise across industries – consumer, automotive, enterprise, aerospace, healthcare etc.

- Produces high mix / low-medium volume products. Great for prototypes and new product introduction.

- Flexible production set-up allowing quick ramp up and shifts in output.

Jabil

- One of the world’s largest manufacturing solutions providers. Revenues of over $29 billion.

- Operates several manufacturing campuses in China including sites in Guangzhou, Shenzhen, Shanghai etc.

- Expertise in consumer electronics, telecom, enterprise computing, healthcare etc.

- Focuses on medium to high volume production. Quality certifications like ISO 13485.

- End-to-end capabilities from design to production, supply chain and aftermarket services.

Sanmina

- Leading integrated manufacturing solutions company with revenues over $6 billion.

- State of the art facility in Suzhou, China with high-mix / medium volume capacity.

- Broad expertise in electronics manufacturing across industries like communications, medical, defense, automotive etc.

- Strong engineering capabilities for new product introduction and ramp to volume production.

- Complete turnkey solutions encompassing manufacturing, logistics and repair services.

Venture

- Singapore MNC providing electronics manufacturing services and solutions.

- Extensive operations in China with facilities in Shanghai, Suzhou, Xiamen, Wuxi etc. Employs over 40,000 staff.

- Specializes in high complexity PCB assemblies for networking and communications infrastructure.

- Excellent technical expertise with engineering resources across China.

- Capabilities spanning design support, manufacturing, fulfilment and aftermarket services.

Benchmark

- One of the Top 10 EMS companies globally headquartered in Taiwan.

- Several advanced facilities across Suzhou, Dongguan, Shanghai etc. in China.

- Broad expertise in computing, data networking, telecom infrastructure, medical, automotive and IoT products.

- Strong engineering design, prototyping and NPI capabilities.

- Offerings encompass manufacturing, system integration, precision machining/tooling etc.

Inventec

- Major Taiwanese ODM company supplying ICT products and solutions globally.

- Operates large production facilities in Shanghai, Nanjing, Chongqing, Taicang and other cities in China.

- Key products include notebooks, servers, storage, switches, routers, telecom equipment etc.

- Significant expertise in higher complexity PCB assemblies for servers and networking products.

- End-to-end ODM services from system design, components sourcing to logistics and after sales service.

Tips for Selecting the Right PCB Assembly Partner

Here are some useful tips for OEMs/ODMs to select the right PCB assembly partner in China:

- Clearly define production requirements – volumes, complexity, quality expectations, budget etc.

- Evaluate technical capabilities by site visits, qualification samples etc.

- Validate quality certifications, customer references, facilities and staff.

- Get quotes from multiple manufacturers for comparison. But don’t decide only on price.

- Select partners with relevant experience in your product application area.

- Consider long term factors like scalability, stability, customer focus etc.

- Start with small orders first to test capabilities and quality before larger orders.

- Maintain frequent communication and timely feedback during product ramp up.

- Opt for turnkey providers offering value-added services for convenience.

- Visit facilities personally if possible to directly assess manufacturing infrastructure.

- Don’t neglect compliance factors like environmental, labor, data protection etc.

Conclusion

China offers a wide range of competent PCB assembly manufacturers to choose from. With diligent partner evaluation and selection considering key factors like technical expertise, quality systems, production capacity, costs and customer service, OEMs can find the right partner to deliver high quality, timely and cost-effective PCB assembly and contract manufacturing solutions in China. Maintaining close communication and building long term partnerships based on performance and trust are key for success.

Frequently Asked Questions

Q1. What are the key advantages of outsourcing PCB assembly to China?

Some of the main advantages include:

- Cost savings – Lower labor and production costs compared to the US or Europe.

- High production capacities – Large number of manufacturers provide big scale at competitive rates.

- Technical capabilities – Availability of advanced assembly technologies and skills.

- Supply chain access – Proximity to upstream component suppliers in China.

- Time to market – Faster manufacturing and product launch.

Q2. What types of PCBs are typically assembled in China?

All types and complexities of PCB assemblies can be handled in China including:

- Single sided, double sided, multilayer, HDI, flex, rigid-flex.

- PCBs with leadless components like 0201 size chips, BGAs, CSPs etc.

- High density boards with fine lines, microvias, tight tolerances etc.

- Simple consumer electronics PCBs to highly complex communication boards.

Q3. What are some alternatives to using PCB assembly service in China?

Some alternatives include:

- Using PCB assembly partners in low cost locations like Southeast Asia, Mexico, Eastern Europe etc.

- Building a small in-house assembly line for proprietary products in lower volumes.

- Near-shoring manufacturing closer to the target market for faster turnaround.

- Leveraging contract manufacturers with facilities globally and allocating by region.

- Exploring newer options like advanced manufacturing technologies, on-demand assembly etc.

Q4. How to ensure and validate the quality of PCB assemblies from China?

Tips to ensure and validate quality:

- Check for quality certifications like ISO 9001, IATF 16949 etc.

- Review test and inspection equipment – automated optical, x-ray, AOI etc.

- Evaluate process controls during assembly, SMT, post-production testing.

- Get samples built and inspected based on acceptance standards like IPC Class 2 or 3.

- Perform audits of facilities, processes, equipment maintenance, data, staff skills etc.

- Do regular quality monitoring when production starts through inspections, testing.

Q5. What documents are required for quoting and ordering PCB assembly services in China?

Typical documents needed are:

- Gerber files for PCB fabrication released for manufacturing.

- Bill of materials (BOM) with approved vendor list for components.

- Assembly drawings with reference designators.

- Centroid or XY placement data for pick and place machine.

- Mechanical drawings for enclosures etc. if box build included.

- Quality acceptance standards – IPC class, workmanship requirements etc.

- Target costs, volumes, delivery schedule, product roadmap if applicable.

Leave a Reply