Introduction to Rigid-flex PCBs

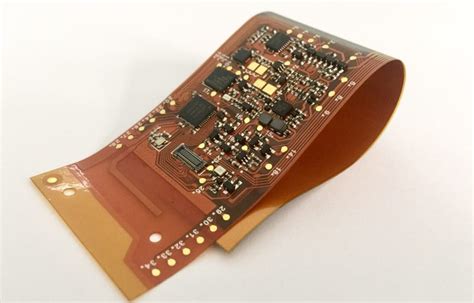

Rigid-flex PCBs are a unique combination of rigid and flexible printed circuit boards that offer numerous advantages over traditional PCBs. These boards consist of rigid and flexible substrates that are laminated together, allowing for three-dimensional packaging and improved electrical performance. Rigid-flex PCBs are widely used in various industries, including aerospace, medical devices, automotive, and consumer electronics, due to their ability to reduce weight, save space, and enhance reliability.

When it comes to manufacturing rigid-flex PCBs, choosing the right manufacturer is crucial to ensure the quality and reliability of your final product. In this article, we will discuss nine essential tips to help you select the best rigid-flex PCB manufacturer for your needs.

Tip 1: Look for Experience and Expertise

One of the most important factors to consider when choosing a rigid-flex PCB manufacturer is their experience and expertise in the field. Rigid-flex PCB manufacturing is a complex process that requires specialized knowledge and skills. Look for a manufacturer with a proven track record of successfully producing high-quality rigid-flex PCBs for various applications.

An experienced manufacturer will have a deep understanding of the materials, design considerations, and manufacturing techniques involved in producing rigid-flex PCBs. They should be able to provide valuable insights and recommendations based on your specific requirements and help you optimize your design for manufacturability and reliability.

Tip 2: Evaluate Manufacturing Capabilities

When evaluating potential rigid-flex PCB manufacturers, it is essential to assess their manufacturing capabilities. A capable manufacturer should have state-of-the-art equipment and facilities to handle the complex fabrication process of rigid-flex PCBs. Some key manufacturing capabilities to look for include:

- High-precision lamination equipment

- Advanced drilling and routing machines

- Automated optical inspection (AOI) systems

- 3D modeling and design verification tools

- Controlled impedance testing equipment

A manufacturer with advanced manufacturing capabilities will be able to produce high-quality rigid-flex PCBs with tight tolerances, minimal defects, and consistent performance.

Tip 3: Check for Quality Certifications

Quality certifications are a good indicator of a manufacturer’s commitment to producing high-quality products and adhering to industry standards. When choosing a rigid-flex PCB manufacturer, look for certifications such as:

- ISO 9001: Quality Management System

- IATF 16949: Quality Management System for Automotive Industry

- AS9100: Quality Management System for Aerospace Industry

- ISO 13485: Quality Management System for Medical Devices

- IPC-6013: Qualification and Performance Specification for Flexible Printed Boards

These certifications demonstrate that the manufacturer has established quality management systems and follows strict quality control procedures to ensure consistent product quality and reliability.

Tip 4: Consider the Manufacturer’s Design Support

Designing rigid-flex PCBs can be challenging, especially if you are new to the technology. Look for a manufacturer that offers comprehensive design support to help you optimize your design for manufacturability, reliability, and cost-effectiveness. A good manufacturer should have a team of experienced engineers who can provide the following:

- Design review and feedback

- Material selection guidance

- Stack-up and layer configuration recommendations

- Signal integrity analysis

- 3D modeling and simulation

Working closely with the manufacturer’s design support team can help you avoid common design pitfalls, reduce development time, and ensure a smooth transition from design to manufacturing.

Tip 5: Assess the Manufacturer’s Communication and Responsiveness

Effective communication and responsiveness are crucial when working with a rigid-flex PCB manufacturer. Look for a manufacturer that is easy to communicate with and responsive to your inquiries and concerns. They should have a dedicated point of contact who can keep you informed about the progress of your project and address any issues that may arise.

A responsive manufacturer will also be proactive in providing updates and seeking your input when necessary. They should have a clear and efficient process for handling revisions, changes, and feedback to ensure that your project stays on track and meets your expectations.

Tip 6: Evaluate the Manufacturer’s Supply Chain Management

A reliable rigid-flex PCB manufacturer should have a robust supply chain management system to ensure the timely availability of raw materials and components. They should have established relationships with reputable suppliers and maintain adequate inventory levels to minimize lead times and avoid production delays.

Additionally, the manufacturer should have a process in place to monitor and control the quality of incoming materials and components. They should perform incoming inspections and testing to ensure that the materials meet the required specifications and standards.

Tip 7: Consider the Manufacturer’s Testing and Inspection Capabilities

Rigorous testing and inspection are essential to ensure the quality and reliability of rigid-flex PCBs. Look for a manufacturer that has comprehensive testing and inspection capabilities to verify the performance and integrity of your boards at various stages of the manufacturing process. Some key testing and inspection capabilities to consider include:

- Flying probe testing

- In-circuit testing (ICT)

- Functional testing

- Thermal cycling and shock testing

- X-ray inspection

- Cross-sectioning analysis

A manufacturer with advanced testing and inspection capabilities will be able to identify and address any issues early in the process, reducing the risk of field failures and ensuring the overall quality of your final product.

Tip 8: Evaluate the Manufacturer’s Pricing and Lead Times

Pricing and lead times are important considerations when choosing a rigid-flex PCB manufacturer. While it may be tempting to choose the lowest-priced option, it is essential to consider the overall value provided by the manufacturer. Look for a manufacturer that offers competitive pricing without compromising on quality, reliability, and service.

When evaluating lead times, consider the manufacturer’s production capacity, supply chain efficiency, and ability to handle rush orders if necessary. A manufacturer with shorter lead times and flexible production capabilities will be better equipped to meet your project deadlines and accommodate any changes in your requirements.

Tip 9: Consider the Manufacturer’s Customer Support and Service

Finally, consider the level of customer support and service provided by the rigid-flex PCB manufacturer. A good manufacturer should have a dedicated customer support team that is knowledgeable, responsive, and proactive in addressing your needs and concerns. They should be willing to go the extra mile to ensure your satisfaction and the success of your project.

Look for a manufacturer that offers value-added services such as design assistance, prototyping, and post-sales support. They should also have a clear and fair process for handling returns, replacements, and warranty claims.

FAQs

-

What is the difference between rigid and rigid-flex PCBs?

Rigid PCBs are made entirely of rigid substrates, while rigid-flex PCBs combine rigid and flexible substrates laminated together. Rigid-flex PCBs offer greater design flexibility, reduced weight and size, and improved reliability compared to traditional rigid PCBs. -

What industries commonly use rigid-flex PCBs?

Rigid-flex PCBs are widely used in industries such as aerospace, medical devices, automotive, consumer electronics, and telecommunications. These industries require high-density packaging, reliability, and flexibility in their electronic designs. -

How do I determine if a rigid-flex PCB is the right choice for my project?

Consider using a rigid-flex PCB if your project requires: - Three-dimensional packaging or complex board shapes

- Reduced weight and size compared to traditional rigid PCBs

- High reliability and resistance to vibration and shock

- Dynamic flexing or bending during operation

-

Integration of multiple electronic components or subsystems

-

What should I provide to a rigid-flex PCB manufacturer for a quote?

To obtain an accurate quote from a rigid-flex PCB manufacturer, provide the following information: - Detailed design files (Gerber, ODB++, or CAD files)

- Bill of Materials (BOM)

- Quantity and delivery requirements

-

Any special requirements or certifications needed

-

How can I ensure the reliability of my rigid-flex PCBs?

To ensure the reliability of your rigid-flex PCBs: - Choose a reputable and experienced manufacturer

- Follow best practices for rigid-flex PCB design

- Use high-quality materials and components

- Perform thorough testing and inspection during the manufacturing process

- Work closely with the manufacturer to address any issues or concerns

Conclusion

Choosing the right rigid-flex PCB manufacturer is essential to ensure the success of your project and the quality and reliability of your final product. By considering factors such as experience, manufacturing capabilities, quality certifications, design support, communication, supply chain management, testing and inspection, pricing and lead times, and customer support, you can make an informed decision and select the best manufacturer for your needs.

Remember to work closely with your chosen manufacturer throughout the design and manufacturing process to ensure that your project stays on track and meets your requirements. By following these tips and partnering with a reputable rigid-flex PCB manufacturer, you can unlock the full potential of this innovative technology and bring your electronic designs to life.

Leave a Reply