1. Safety Concerns

Handling Hazardous Chemicals

One of the primary disadvantages of PCB etching at home is the need to handle hazardous chemicals. The etching process typically involves using corrosive substances such as ferric chloride or ammonium persulfate. These chemicals can cause skin irritation, eye damage, and respiratory issues if not handled properly.

To mitigate these risks, it’s essential to:

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and a respirator

- Work in a well-ventilated area

- Store chemicals in clearly labeled containers and keep them out of reach of children and pets

Disposing of Chemical Waste

After the etching process, you’ll be left with chemical waste that must be disposed of responsibly. Improper disposal can lead to environmental damage and potential legal consequences. Check with your local authorities for guidelines on how to safely dispose of chemical waste in your area.

2. Time-Consuming Process

Preparation and Etching

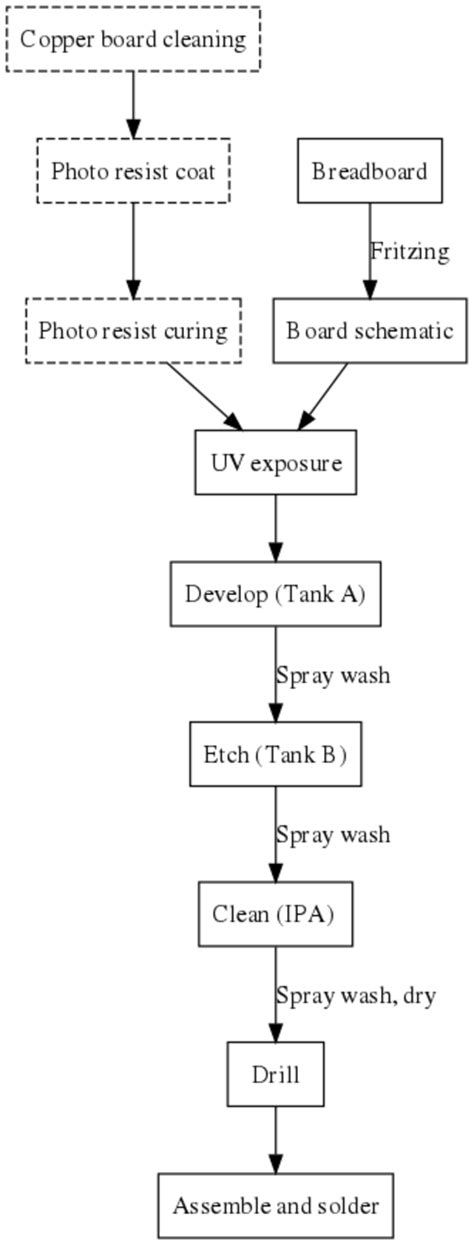

Creating PCBs at home can be a time-consuming process, especially for beginners. The preparation stage involves designing the PCB layout, printing the design onto a transparency film, and transferring the design onto the copper-clad board. The etching process itself can take anywhere from a few minutes to several hours, depending on the size and complexity of the board.

Troubleshooting and Rework

Even with careful preparation, there’s a chance that your etched PCB may have issues such as incomplete etching, overetching, or poor connections. Troubleshooting and reworking these problems can add significant time to the overall process.

3. Limited PCB Complexity

Single-Sided Boards

Home PCB etching is generally limited to single-sided boards, which means that all the components and traces are on one side of the board. This limitation can restrict the complexity and functionality of your projects.

Trace Width and Spacing

When etching PCBs at home, it can be challenging to achieve very fine trace widths and spacing between traces. This limitation can affect the size and performance of your circuits, especially for high-frequency or high-density designs.

4. Equipment and Material Costs

Initial Investment

To get started with PCB etching at home, you’ll need to invest in various equipment and materials. This can include:

- PCB design software

- Laser printer or photoplotter

- UV exposure unit

- Etching tank and heater

- Drill press or hand drill

- Copper-clad boards

- Etching chemicals

- Personal protective equipment

While some of these items can be found at relatively low costs, the initial investment can still be substantial, especially for hobbyists on a tight budget.

Ongoing Costs

In addition to the initial investment, there are ongoing costs associated with PCB etching at home. These can include:

- Replacing consumables such as copper-clad boards, transparencies, and etching chemicals

- Maintenance and repair of equipment

- Electricity costs for running equipment

5. Inconsistent Results

Environmental Factors

The success of your home-etched PCBs can be influenced by various environmental factors such as temperature, humidity, and air quality. Fluctuations in these conditions can lead to inconsistent results, such as uneven etching or poor adhesion of the resist layer.

Human Error

As with any manual process, human error can also contribute to inconsistent results in home PCB etching. Mistakes in exposure time, etching duration, or agitation of the etching solution can all impact the quality of the final board.

6. Limited PCB Size

Equipment Constraints

The size of the PCBs you can etch at home is often limited by the size of your equipment, such as your UV exposure unit or etching tank. This can restrict the scope of your projects and may require you to break larger designs into smaller, interconnected boards.

Material Availability

Copper-clad boards for home etching are typically available in a limited range of sizes. If you require larger or custom-sized boards, you may need to source them from specialized suppliers, which can be more expensive and time-consuming.

7. Steep Learning Curve

Understanding the Process

PCB etching at home involves a series of steps that require a good understanding of the underlying principles. Beginners may find it challenging to grasp concepts such as resist application, exposure times, and etching rates. This learning curve can lead to frustration and wasted materials in the early stages.

Troubleshooting Skills

When issues arise during the etching process, troubleshooting skills are essential. Identifying and resolving problems such as underexposure, overetching, or poor resist adhesion can be difficult for those new to the process. Developing these skills takes time and practice.

8. Messy and Smelly Process

Chemical Odors

The chemicals used in PCB etching, such as ferric chloride or ammonium persulfate, can produce strong and unpleasant odors. These odors can linger in your workspace and may be difficult to eliminate without proper ventilation.

Stains and Spills

Etching chemicals can also cause stains on surfaces, clothing, and skin. Accidental spills can be difficult to clean up and may lead to permanent damage. It’s essential to work in a dedicated space with appropriate protective measures to minimize the risk of stains and spills.

9. Space Requirements

Dedicated Workspace

To safely and effectively etch PCBs at home, you’ll need a dedicated workspace that is well-ventilated and free from potential hazards. This space should be large enough to accommodate your equipment and provide ample room for handling chemicals and materials.

Storage Space

In addition to a dedicated workspace, you’ll need storage space for your equipment, materials, and chemical waste. This can be challenging in smaller homes or apartments where space is at a premium.

10. Alternatives to Home Etching

PCB Fabrication Services

For those who find the disadvantages of home PCB etching too daunting, there are alternatives available. PCB fabrication services, such as those offered by online manufacturers, can provide high-quality, professional-grade PCBs at relatively low costs. These services offer a wide range of options, including multi-layer boards, solder masks, and silkscreen printing.

Breadboarding and Prototyping

For simpler projects or initial prototypes, breadboarding can be a quick and easy alternative to etching PCBs. Breadboards allow you to create temporary circuits without the need for soldering or etching. Once your design is finalized, you can then consider moving to a more permanent PCB solution.

FAQ

-

Is PCB etching at home safe?

PCB etching at home can be safe if proper precautions are taken. This includes wearing appropriate personal protective equipment, working in a well-ventilated area, and handling and disposing of chemicals responsibly. However, there are inherent risks involved, and it’s essential to understand and mitigate these risks before beginning. -

How much does it cost to get started with PCB etching at home?

The cost of getting started with PCB etching at home can vary depending on the equipment and materials you choose. A basic setup can cost anywhere from a few hundred to a few thousand dollars. It’s important to consider both the initial investment and ongoing costs when deciding if home PCB etching is right for you. -

Can I etch complex, multi-layer PCBs at home?

Etching complex, multi-layer PCBs at home can be very challenging and is not recommended for beginners. Home etching is generally limited to single-sided boards with relatively simple designs. For more complex projects, it’s often better to use a professional PCB fabrication service. -

How long does it take to etch a PCB at home?

The time it takes to etch a PCB at home can vary depending on the size and complexity of the board, as well as your experience level. The preparation stage, including design and resist application, can take several hours. The actual etching process can range from a few minutes to several hours, depending on the etching method and solution strength. -

Are there any legal considerations when etching PCBs at home?

When etching PCBs at home, it’s essential to comply with local laws and regulations regarding the use and disposal of hazardous chemicals. Failure to do so can result in fines or legal consequences. It’s also important to consider any potential impact on your living space, such as fumes or odors that may affect neighbors in a multi-unit dwelling. Always check with your local authorities for specific guidelines and restrictions.

Conclusion

PCB etching at home can be a rewarding and educational experience for electronics enthusiasts. However, it’s crucial to weigh the potential disadvantages before diving in. Safety concerns, time and cost investments, and limitations on PCB complexity and size are all important factors to consider. For those who find the challenges of home etching too daunting, alternatives such as professional PCB fabrication services or breadboarding can provide a more accessible path to bringing their electronic projects to life.

| Aspect | Consideration |

|---|---|

| Safety | Handling hazardous chemicals, PPE, ventilation, waste disposal |

| Time Investment | Preparation, etching, troubleshooting, rework |

| PCB Complexity | Single-sided boards, trace width and spacing limitations |

| Equipment and Materials | Initial investment, ongoing costs |

| Results Consistency | Environmental factors, human error |

| PCB Size | Equipment constraints, material availability |

| Learning Curve | Understanding the process, troubleshooting skills |

| Workspace | Dedicated space, ventilation, storage |

| Alternatives | PCB fabrication services, breadboarding, prototyping |

By carefully evaluating these factors and understanding the potential drawbacks, you can make an informed decision about whether PCB etching at home is the right choice for your needs and resources. With proper planning, preparation, and safety measures, home PCB etching can be a fulfilling and cost-effective way to bring your electronic designs to life.

Leave a Reply